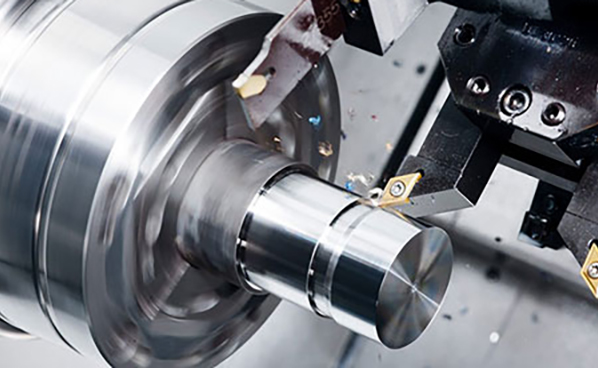

In the world of precision manufacturing, where digital designs meet physical reality, a universal language acts as the critical bridge. For CNC (Computer Numerical Control) machines, the undisputed standard tool language is G-code. This alphanumeric programming language is the fundamental set of instructions that directs every movement, speed, and function of a CNC machine tool, transforming a 3D CAD model into a tangible, high-precision component.

Understanding this language is not just academic; it’s central to grasping how a manufacturer like GreatLight CNC Machining Factory reliably converts your complex designs into flawless parts.

H2: Deconstructing G-code: The DNA of CNC Instructions

At its core, G-code is a sequential list of commands that tell the machine:

Where to move (X, Y, Z coordinates, and often A, B, C rotary axes in 5-axis machining).

How fast to move (feed rates).

How fast to spin the tool (spindle speed).

Which path to follow (linear or circular interpolation).

When to turn coolant on or off, and much more.

A typical block of G-code might look like this:

G01 X100.5 Y25.2 Z-10.0 F500 S12000

This command instructs the machine to perform a linear move (G01) to the coordinates X100.5mm, Y25.2mm, Z-10.0mm at a feed rate of 500 mm per minute (F500) with the spindle rotating at 12,000 RPM (S12000).

H3: The Ecosystem Around G-code: From CAD to Finished Part

G-code is rarely written manually for complex parts today. Instead, it is generated through a critical software process:

CAD (Computer-Aided Design): The journey begins with your 3D model, defining the part’s final geometry.

CAM (Computer-Aided Manufacturing): This is where engineering expertise shines. A CAM programmer, using software like Mastercam, Siemens NX, or HyperMill, imports the CAD model. They then define:

Tool Selection: Choosing the optimal end mill, drill, or turning tool from a vast digital library.

Toolpaths: Strategically planning the most efficient and accurate routes for the tool to remove material.

Cutting Parameters: Precisely calculating speeds, feeds, and depth of cuts based on the material (e.g., aerospace aluminum, medical-grade titanium, or PEEK plastic).

Post-Processing: The CAM software’s generic toolpath data is translated by a post-processor—a machine-specific translator—into the exact G-code dialect that the particular brand and model of CNC machine (e.g., a DMG MORI 5-axis mill or a GreatLight-maintained precision machining center) understands.

H4: Beyond the “Standard”: Dialects and Best Practices

While G-code follows ISO 6983 standards, variations exist—similar to regional dialects. A Fanuc-style control system might use slightly different codes than a Heidenhain or Siemens system. A top-tier manufacturer’s expertise lies in:

Optimizing Code: Writing lean, efficient code that minimizes unnecessary machine movements, reduces cycle time, and prolongs tool life.

Ensuring Compatibility: Using perfectly calibrated post-processors to ensure zero translation errors between the CAM system and the machine tool.

Implementing Advanced Techniques: Utilizing M-codes (miscellaneous functions for machine control) and custom macros for complex, repetitive operations, ensuring consistency in high-volume production runs.

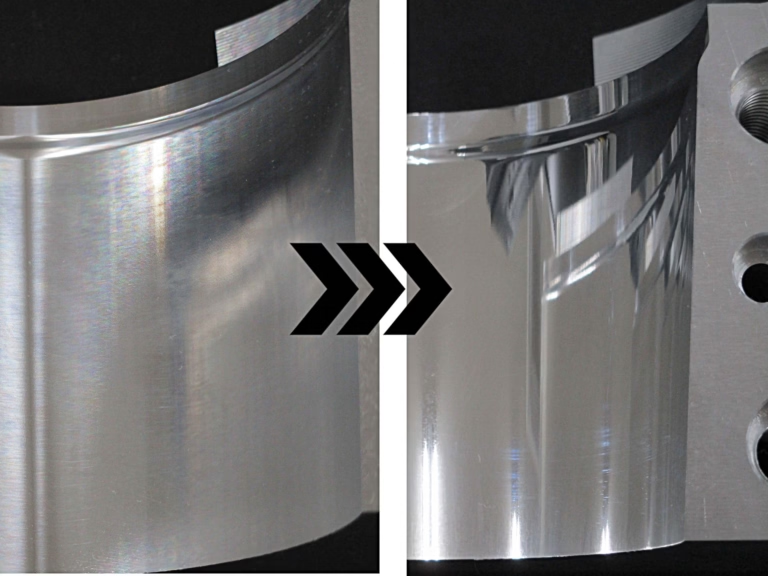

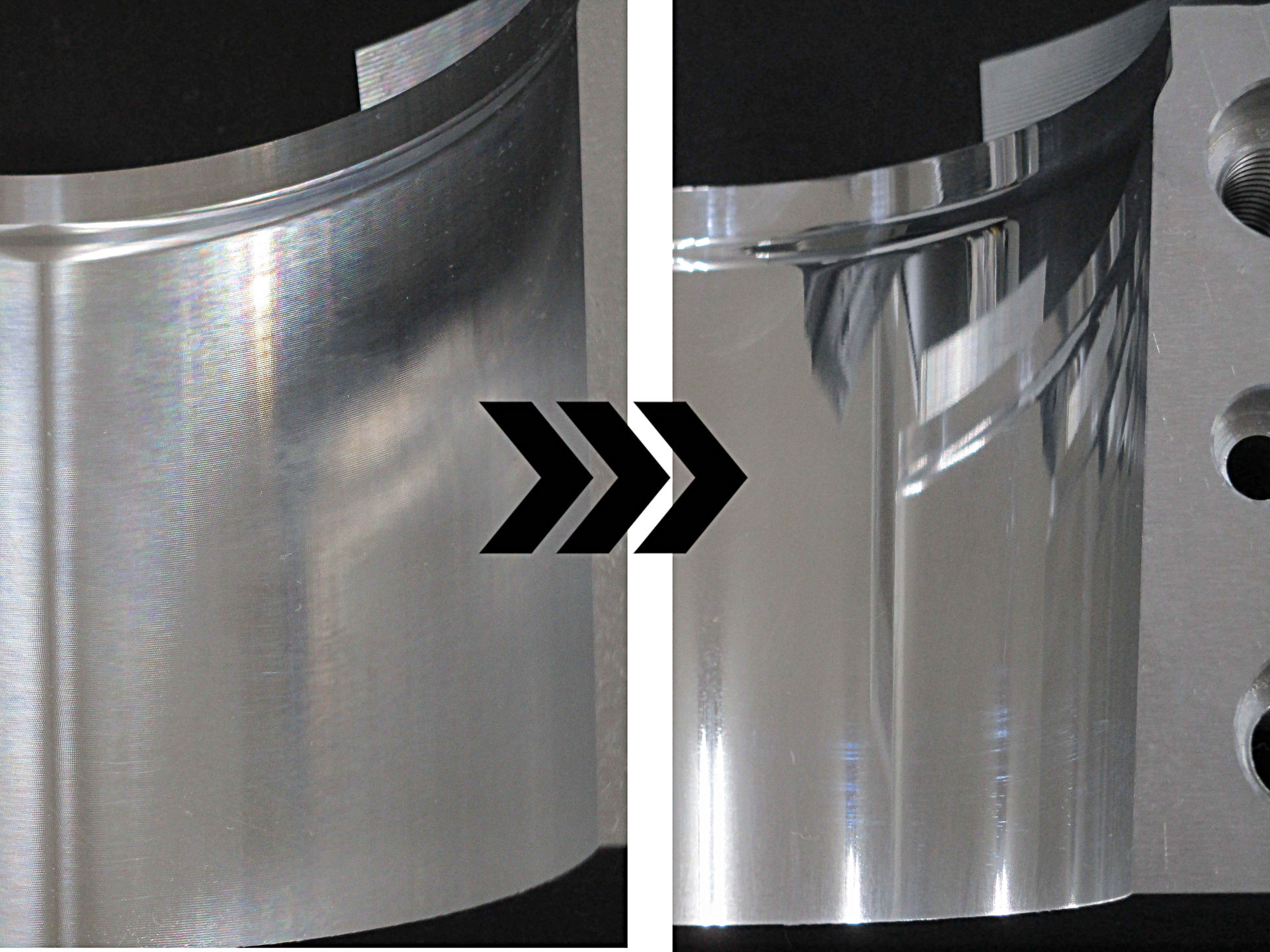

This deep command over the CNC language is what separates a basic machine shop from a true engineering partner. It directly impacts part accuracy, surface finish, and overall manufacturing cost.

H2: Why Mastery of This “Language” is Your Guarantee of Quality

When you commission a precision part, you are essentially entrusting your design to the manufacturer’s ability to “speak” and “execute” this language flawlessly. Here’s how GreatLight Metal leverages this expertise as part of our integrated manufacturing solution:

Precision Translation of Intent: Our engineers don’t just run software; they interpret your design intent. We analyze geometries for manufacturability (DFM) and then craft the optimal G-code strategy to achieve your specified tolerances (even down to ±0.001mm where required).

5-Axis Machining Complexity: For intricate components requiring simultaneous multi-axis movement, the G-code program becomes exponentially more complex. Our experience with advanced 5-axis CNC machining ensures that this code produces smooth, vibration-free toolpaths, which is critical for complex contours and thin-walled structures common in aerospace or automotive engine components.

Seamless Full-Process Integration: From the initial G-code for a 3D printed prototype to the final code for mass production via CNC machining or die casting, our command over this standard language ensures consistency and traceability across our entire service chain.

Systematic Reliability Underpinned by Certification: Our rigorous adherence to ISO 9001:2015 for quality management and IATF 16949 for automotive processes means our code generation, verification, and machine operation follow documented, audited procedures. This systemic approach minimizes human error and ensures every part run from a program is identical to the last.

Conclusion

The question, “What is the standard tool language for CNC machines?” finds its answer in G-code. However, the deeper truth is that the quality of your custom precision part hinges not on the existence of this language, but on the fluency, experience, and systematic discipline with which your manufacturing partner wields it. It is the bedrock upon which digital designs are reliably brought to life. Choosing a partner like GreatLight CNC Machining Factory, whose operations are built on mastering this fundamental language within a framework of advanced equipment and international certifications, is the most direct path to ensuring your vision is executed with unwavering precision and reliability.

FAQ

Q1: Can I provide my own G-code to a machine shop?

A: While technically possible, it is generally not recommended unless you are intimately familiar with the specific machine tool, its tooling, and fixture setup at the shop. Ineffective or unsafe code can damage machines and tools. Reputable manufacturers prefer to generate code in-house using their verified post-processors and machining databases to guarantee safety, efficiency, and quality.

Q2: Is learning G-code necessary for designers?

A: It is not necessary, but it is highly beneficial. A basic understanding of G-code and CNC limitations empowers designers to create parts that are more manufacturable (Design for Manufacturing or DFM), potentially reducing cost and lead time. Knowing that sharp internal corners or excessively deep, thin features are challenging to machine can inform better design choices.

Q3: Does 3D printing use G-code?

A: Yes, in principle. Most fused deposition modeling (FDM) 3D printers use a variant of G-code (often generated by a “slicer” software) to control nozzle movement, extrusion speed, and bed temperature. For industrial metal 3D printing (SLM), the process is more complex, but the motion of the laser or powder re-coater is still governed by a numerically controlled language analogous to G-code.

Q4: How does a manufacturer ensure the G-code is error-free before machining?

A: Multiple verification steps are used:

CAM Software Simulation: The toolpath is visually simulated within the CAM software to check for collisions, gouges, or inefficient motions.

Verification Software: Dedicated packages provide more advanced in-depth analysis.

Dry Runs: The machine executes the program without the part or with a safe distance offset to confirm movement logic.

Proven Post-Processor Libraries: Using well-established, machine-specific post-processors eliminates translation errors. At GreatLight Metal, this verification is embedded within our ISO-certified workflow.

Q5: For ultra-high-precision parts, what special considerations are given to the CNC program?

A: For micron-level tolerances, every aspect is scrutinized: code is optimized for thermally stable toolpaths to minimize heat-induced distortion, climb vs. conventional milling strategies are carefully selected for optimal surface finish, and compensation codes for tool wear and machine deflection are actively employed. This level of programming sophistication is a hallmark of a specialist in precision 5-axis CNC machining services.