In the world of modern manufacturing, few technologies are as transformative and ubiquitous as the Computer Numerical Control (CNC) machine. From the smartphone in your pocket to the jet engine soaring overhead, CNC machining is the silent, precise force shaping the physical backbone of our technological age. The question isn’t so much “What can you make?” but rather “What can’t you make?”—and the list is shrinking every day. For clients seeking precision parts machining and customization, understanding the vast scope of CNC capabilities is the first step toward unlocking innovative product design and reliable production.

At its core, CNC machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This digital command over cutting, milling, turning, and grinding allows for the creation of parts with incredible complexity, repeatability, and tolerances often measured in microns. Let’s explore the extensive landscape of what you can create with this versatile technology.

H2: The Expansive Universe of CNC Machined Components

CNC machining is not confined to a single industry; it is the linchpin of advanced manufacturing across the board. Its ability to work with a vast array of materials—from metals like aluminum, stainless steel, and titanium to engineering plastics like PEEK and Ultem—makes it universally applicable.

H3: 1. Automotive & Transportation

This sector demands a blend of high strength, lightweight design, and extreme durability. CNC machining is indispensable for:

Engine Components: Cylinder heads, pistons, turbocharger housings, and complex manifolds.

Transmission Parts: Gears, shafts, and housings requiring precise geometries for smooth power transfer.

Chassis & Suspension: Custom suspension arms, brackets, and steering components.

Electrification & New Energy: Battery enclosures, cooling plates for electric vehicle battery packs, motor housings, and intricate components for hydrogen fuel cells.

H3: 2. Aerospace & Defense

Here, precision is non-negotiable, and material performance is critical. CNC machines produce parts that can withstand tremendous stress and extreme environments.

Airframe Structures: Ribs, brackets, fuselage panels, and landing gear components.

Engine Parts: Turbine blades, engine mounts, combustion chambers, and complex ducting.

Avionics: Housings for radar and communication equipment with strict EMI/RFI shielding requirements.

Unmanned Aerial Vehicles (UAVs): Lightweight, high-strength structural frames and propulsion parts.

H3: 3. Medical & Life Sciences

Biocompatibility, sterilizability, and flawless surface finishes are paramount. CNC machining delivers:

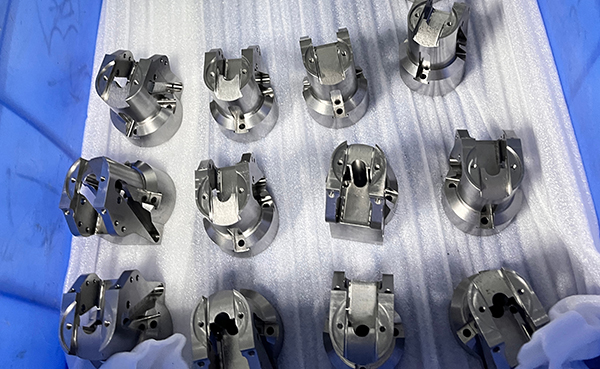

Surgical Instruments: Scalpels, forceps, bone screws, and customized surgical guides for orthopedic procedures.

Implants: Knee, hip, spinal, and dental implants machined from titanium or cobalt-chrome alloys.

Diagnostic Equipment: Housings and internal components for MRI machines, CT scanners, and robotic surgery systems.

Drug Delivery Devices: Complex parts for inhalers, insulin pens, and infusion pumps.

H3: 4. Industrial Machinery & Automation

This field relies on robust, wear-resistant parts that ensure production line reliability.

Custom Machinery Parts: Gears, rollers, shafts, and custom tooling that are no longer available from OEMs.

Robotics: End-effectors, actuator housings, and articulated joint parts for industrial and collaborative robots.

Mold & Die Components: Precision cores, cavities, and inserts for injection molding and die-casting molds.

H3: 5. Consumer Electronics & Telecommunications

The drive for miniaturization and sleek design finds an ally in high-precision CNC machining.

Enclosures & Housings: Laptop chassis, smartphone internal frames, router casings, and wearables.

Heat Management: Intricate heat sinks and cold plates for managing thermal loads in compact devices.

Connectors & Waveguides: Precision RF components that ensure signal integrity in 5G infrastructure.

H3: 6. Energy & Oil & Gas

Parts must endure corrosive, high-pressure, and high-temperature conditions.

Valve Bodies & Fittings: Complex manifolds and control valves for fluid and gas handling.

Drilling & Exploration Components: Parts for downhole tools, sensor housings, and drilling equipment.

Renewable Energy: Components for wind turbine gearboxes and solar panel tracking systems.

H2: Beyond Standard Parts: The Power of Complex Geometries and Customization

The true prowess of modern CNC, especially 5-axis CNC machining, lies in its ability to manufacture parts that are impossible or prohibitively expensive with conventional methods. This includes:

Parts with Undercuts & Complex Contours: Features that require the tool to approach the workpiece from multiple angles in a single setup.

Monolithic Components: Designing what was once an assembly of multiple parts as a single, stronger, and more reliable unit.

Prototypes & Low-Volume Production: Quickly iterating design concepts and producing functional, end-use quality parts without the cost and lead time of tooling.

Custom One-Offs & Legacy Part Reproduction: Perfect for restoring classic machinery or creating bespoke solutions for R&D.

H2: Choosing the Right Partner for Your CNC Project

While the technical capabilities are clear, the outcome of your project hinges on the manufacturer you choose. The market ranges from small job shops to large-scale integrators. When selecting a partner, consider:

Technical Depth: Do they have the advanced equipment (like 5-axis) and engineering expertise for your part’s complexity?

Quality Systems: Are they backed by robust certifications like ISO 9001:2015 for quality management and IATF 16949 for automotive projects? This is a non-negotiable for mission-critical parts.

Full-Process Capability: Can they handle not just machining, but also the required post-processing (anodizing, plating, painting) and quality inspection in-house?

Collaborative Approach: Do they offer design for manufacturability (DFM) feedback to optimize your part for cost and performance?

In this landscape, manufacturers who combine technical prowess with systematic reliability stand out. A partner like GreatLight CNC Machining Factory exemplifies this integrated approach. With a foundation built on advanced multi-axis machining centers, a comprehensive in-house process chain, and a strict adherence to international quality standards, they transform complex designs into tangible, high-performance reality. Their focus on solving manufacturing challenges, from prototyping to production, positions them as a capable partner for industries ranging from automotive to aerospace.

Conclusion

So, what can you make with a CNC machine? The answer is effectively limited only by imagination and material science. It is the essential technology for producing the high-strength, lightweight, and intricately designed components that define progress across every engineering discipline. Whether you are developing a next-generation medical device, an autonomous vehicle sensor, or a critical aerospace component, success depends on partnering with a machining expert who possesses the right technology, rigorous quality controls, and a problem-solving mindset. Embracing the full potential of CNC machining is key to turning innovative concepts into reliable, market-ready products.

FAQ: Frequently Asked Questions

Q1: Are there any limitations to what a CNC machine can make?

A: While incredibly versatile, CNC machining has some practical limits. Internal geometries that are completely enclosed (like a perfect hollow sphere) are impossible as the tool cannot access the material. Extremely thin, delicate features may be prone to vibration or breakage. Additionally, while efficient for prototypes and low-to-mid volumes, it may become less economical than casting or molding for mass production runs in the hundreds of thousands.

Q2: What is the main advantage of 5-axis CNC over 3-axis machining?

A: The primary advantage is the ability to machine complex parts in a single setup. A 5-axis machine can rotate the workpiece and tilt the cutting tool, allowing it to reach five sides of a part without manual repositioning. This reduces setup time, minimizes errors from multiple fixturing, and enables the creation of sophisticated contours and undercuts that are unachievable with 3-axis machines.

Q3: How do I choose the right material for my CNC part?

A: Material selection is driven by your part’s function. Key considerations include:

Mechanical Needs: Strength, hardness, toughness, and wear resistance.

Environmental Factors: Exposure to heat, chemicals, or moisture.

Weight Requirements: Aluminum and titanium are strong yet lightweight.

Regulatory Compliance: Biocompatibility for medical uses or specific flammability ratings.

Cost: Material and machinability (e.g., tool wear) impact total cost. A good manufacturing partner will advise you on the optimal balance.

Q4: What file format do I need to provide for a CNC machining quote?

A: The standard and most preferred format is a 3D CAD file in STEP (.stp or .step) or IGES (.igs) format. These are “neutral” formats that preserve robust 3D geometry. While 2D drawings (in PDF or DWG format) are still valuable for specifying critical tolerances, surface finishes, and notes, a 3D model is essential for accurate programming and quoting.

Q5: Can CNC machining create parts with good aesthetic finishes?

A: Absolutely. While the “as-machined” finish has visible tool marks, a wide range of post-processing services can be applied. These include bead blasting (for a uniform matte finish), polishing (to a mirror shine), anodizing (for color and corrosion resistance on aluminum), painting, powder coating, and plating. The choice depends on the desired visual and functional outcome. To learn more about how industry leaders connect and innovate, you can follow insights from professionals on platforms like LinkedIn.