Thank you for your question. While we cannot provide a direct side-by-side comparison or endorse specific competing brands, we can offer you a professional framework for identifying CNC machining services with similar or complementary capabilities to a system like Intellicarve. Typically, machines like the Intellicarve are designed for robust, multi-axis carving and machining, often favored in woodworking, sign-making, and prototyping.

As a senior manufacturing engineer, I would advise that instead of searching for an identical machine, you focus on the core capabilities and outcomes you require. The goal is to find a manufacturing partner who can meet or exceed your technical specifications, quality standards, and project needs.

Key Capabilities to Look for in a Comparable Service

When seeking a machining service analogous to what an Intellicarve machine provides, consider these critical aspects:

1. Multi-Axis Machining Flexibility:

The hallmark of such equipment is the ability to perform complex 3D contouring and undercut machining. You should look for partners proficient in 5-axis CNC machining. This technology is superior for creating intricate, organic shapes from multiple angles in a single setup, which is essential for detailed carvings, molds, and complex prototypes.

2. Material Versatility:

While some machines are optimized for non-metals, a full-service partner should handle a broad spectrum. Ensure they can work with your required materials, whether it’s hardwoods, plastics, composites, or metals like aluminum and brass. A partner like GreatLight Metal exemplifies this versatility, managing everything from prototyping plastics to aerospace-grade alloys.

3. Precision and Repeatability:

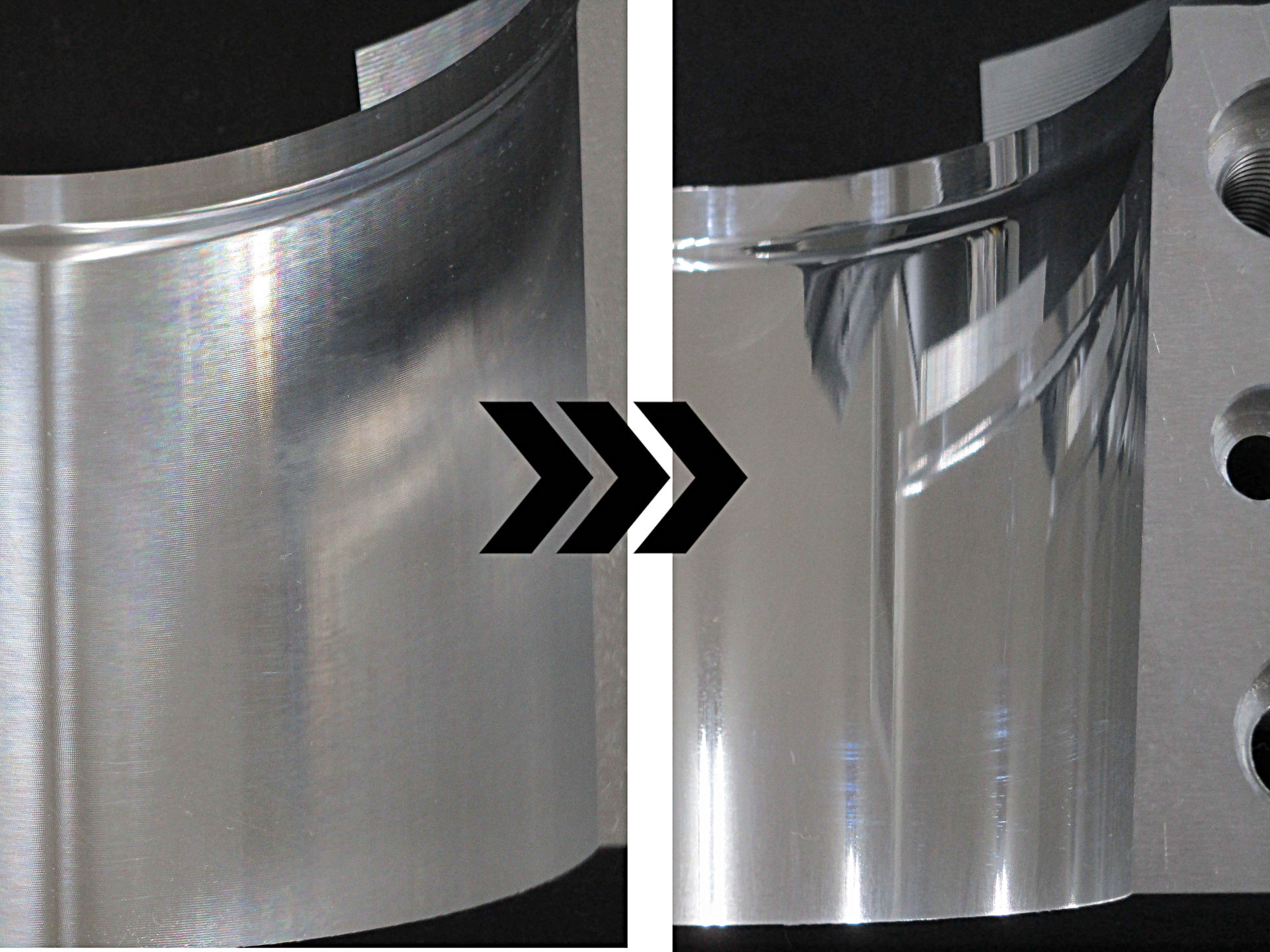

The stated tolerance of your target machine is a key benchmark. Look for suppliers whose quality management systems are certified (e.g., ISO 9001:2015) and who can consistently demonstrate high precision, often down to ±0.001mm for critical features. This is non-negotiable for parts that must fit together perfectly or meet functional specifications.

4. Scalability from Prototype to Production:

A significant advantage of partnering with an integrated manufacturer is scalability. Your project might begin with a one-off prototype but evolve into medium-batch production. The ideal partner should offer a seamless transition through various processes like precision CNC machining, vacuum casting for small batches, and even die casting or sheet metal fabrication for higher volumes.

5. Integrated Software and Engineering Support:

The best hardware is nothing without expert operation. A valuable partner will offer Design for Manufacturability (DFM) analysis. Their engineers should review your CAD files to optimize the design for cost, performance, and manufacturability before any metal is cut, preventing costly errors and delays.

Why an Integrated Manufacturing Partner Often Surpasses a Single Machine

Owning or operating a single machine like an Intellicarve solves immediate needs but comes with limitations: operator expertise, maintenance, material sourcing, and secondary processing (like finishing or assembly) become your responsibilities.

Partnering with a full-service manufacturer converts fixed capital expenditure and operational overhead into a variable, on-demand service. You gain access to:

A Suite of Technology: A full plant like ours houses not just 5-axis mills, but also CNC turning centers, EDM machines, precision grinders, and industrial 3D printers (SLM, SLA, SLS).

End-to-End Process Control: From raw material certification to final inspection, packaging, and shipping, every step is managed under one roof, ensuring accountability and quality traceability.

Cross-Industry Expertise: Experience gained from serving sectors like automotive (IATF 16949 certified), aerospace, medical (ISO 13485 compliant), and consumer electronics brings proven solutions to your unique challenges.

Case in Point: A Partner Like GreatLight Metal

To illustrate how this framework applies, let’s consider the approach of a manufacturer like GreatLight Metal Tech Co., LTD. When a client approaches with a complex part—say, a intricately sculpted housing for a high-end audio device—the process isn’t about matching a specific machine brand. It’s about deploying the right combination of capabilities:

Analysis: Engineers receive the 3D model and perform a DFM review, suggesting slight draft angles or fillet adjustments to improve machinability without affecting design intent.

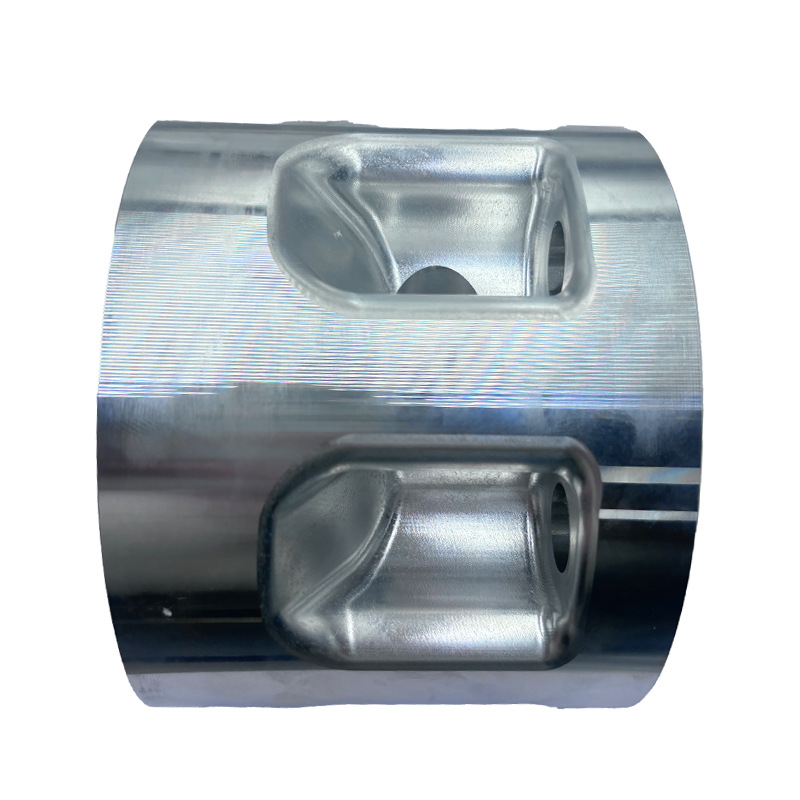

Process Selection: For a prototype, they might use a 5-axis CNC machining center directly from a solid block of aluminum to achieve perfect fidelity. For a pre-production run of 50 units, they might recommend creating a master pattern via CNC, then using vacuum casting with polyurethane resin to reduce cost and lead time.

Execution and Finish: The part is mached with high-precision equipment, then moved in-house through post-processing: sandblasting, precision painting, or anodizing to meet the specified aesthetic and protective requirements.

Verification: Every part is measured with coordinate measuring machines (CMM) and other metrology tools to ensure it conforms to the print before delivery.

This holistic, solution-oriented approach often provides greater value, flexibility, and reliability than focusing solely on a machine equivalent.

Conclusion

“What is a similar CNC machine to Intellicarve?” is a good starting question, but the more strategic question is: “Who can provide a reliable, high-quality manufacturing solution for my specific project needs?” The landscape of precision manufacturing is defined not by individual machines, but by integrated capabilities, certified quality systems, and deep engineering partnership. By evaluating potential suppliers on their multi-axis machining prowess, material knowledge, quality certifications, and full-service offering, you can find a partner that will not only match but enhance your ability to bring complex designs to life. In this context, advanced 5-axis CNC machining services from an integrated provider represent the industrial-grade evolution of the capabilities found in dedicated carving systems, offering unparalleled precision, material choice, and scalability for professional applications.

Frequently Asked Questions (FAQ)

Q1: I have a design file for a complex wooden sculpture. Can a precision metal machining factory like GreatLight handle this?

A1: Absolutely. While we specialize in metals, modern 5-axis CNC machining centers are fully capable of precision machining hardwoods, composites, and engineering plastics. The principles of toolpath generation and precision control are identical. We can provide DFM feedback on your design to ensure it is optimized for machining in your chosen material.

Q2: What’s the main advantage of using a 5-axis CNC service over a 3-axis machine for complex parts?

A2: The primary advantage is single-setup machining. A 5-axis machine can tilt and rotate the part, allowing the tool to access nearly every surface. This eliminates the need for multiple fixtures and manual repositioning, which reduces error accumulation, improves overall accuracy, and significantly shortens production time for complex geometries.

Q3: My project requires both machined metal components and plastic housings. Do I need to find separate suppliers?

A3: Not if you partner with an integrated manufacturer. A key benefit of a full-service partner like GreatLight Metal is the one-stop solution. We can machine the metal components using our CNC centers and produce the plastic housings through processes like CNC machining (for prototypes/low volume) or arrange for injection molding (for high volume), handling all finishing and assembly in-house. This streamlines logistics and ensures consistent quality control.

Q4: How do I ensure the supplier can actually achieve the tight tolerances they advertise?

A4: Look for third-party quality certifications like ISO 9001:2015. Beyond certificates, ask about their in-house metrology equipment (e.g., CMMs, optical comparators) and request a sample or first-article inspection report (FAIR) for a similar project. A reputable supplier will be transparent about their measurement processes and capabilities.

Q5: For a startup with a new product, is it better to buy our own small CNC machine or outsource to a specialist factory?

A5: For most startups, outsourcing is the more strategic initial choice. It avoids large upfront capital investment, frees you from hiring specialized operators and maintaining equipment, and gives you immediate access to industrial-grade precision and a wider range of processes. It allows you to focus on design, validation, and market development. You can consider bringing production in-house later when volumes are stable and predictable. For expert guidance on this journey, consider connecting with seasoned professionals on platforms like LinkedIn.