What Is The CNC Vertical Gantry Milling Machine?

In the highly specialized world of precision parts machining and customization, the CNC vertical gantry milling machine stands as a remarkable piece of equipment. This powerful machine plays a crucial role in modern manufacturing processes, offering a high – level of accuracy, efficiency, and flexibility, especially when it comes to handling large – sized and complex workpieces. If you’re pursuing advanced precision machining, you can learn about precision 5 – axis CNC machining services provided by GreatLight CNC Machining Factory.

How a CNC Vertical Gantry Milling Machine Operates

At its core, a CNC (Computer Numerical Control) vertical gantry milling machine combines computer control technology with milling operations. The term “vertical” indicates that the spindle of the milling cutter is oriented vertically. The “gantry” refers to the frame structure that straddles the worktable, allowing the cutting tools to move precisely along multiple axes in a coordinated manner.

This machine is programmed using computer software to execute a series of complex movements. The operator inputs instructions, including cutting paths, speeds, and depths of cut, into the CNC system. Once the program is set, the machine can operate autonomously, ensuring consistent and accurate results. The vertical gantry design enables it to handle large and heavy workpieces with ease, making it suitable for industries such as aerospace, automotive, and heavy machinery manufacturing.

Key Features and Advantages

High Precision: The CNC control system allows for extremely precise positioning and movement of the cutting tools. This means that parts can be machined to tight tolerances, often up to ±0.001mm or even higher in some high – end models. Such precision is vital for applications where every micron counts, like in the production of engine components or aircraft parts.

Versatility: CNC vertical gantry milling machines can perform a wide range of milling operations, including face milling, end milling, drilling, and boring. They can work with various materials, such as metals (aluminum, steel, titanium), plastics, and composites. This versatility makes them a valuable asset in a manufacturing facility, as they can be used to produce different types of parts for diverse industries.

Efficiency for Large – scale Production: The gantry structure provides a stable platform for machining large workpieces. With rapid tool changes and high – speed spindle rotations, these machines can significantly reduce production time. For high – volume production runs, they can maintain consistent quality and output, improving overall productivity.

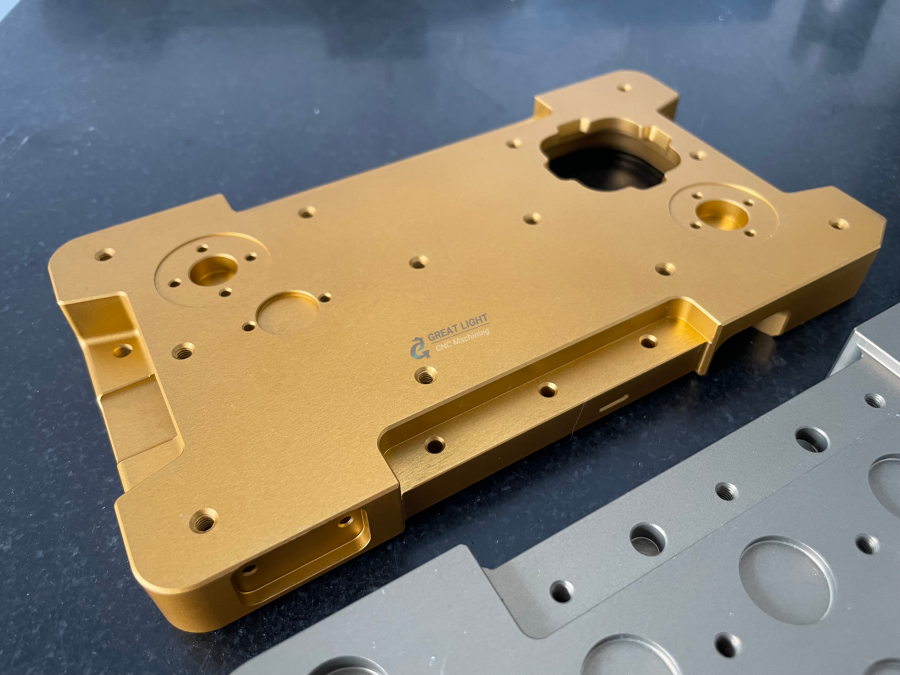

GreatLight CNC Machining Factory’s Competence in Utilizing Gantry Milling Machines

GreatLight CNC Machining Factory is well – equipped with advanced CNC vertical gantry milling machines as part of its comprehensive manufacturing capabilities. Founded in 2011 and located in Chang’an District, Dongguan City, known as the capital of precision hardware mold processing, the factory has deep experience in precision machining.

With a large – scale production area of approximately 7600 square meters and a team of 150 skilled employees, the factory can handle complex machining tasks. Its 127 pieces of precision peripheral equipment include high – end gantry milling machines that support multi – axis machining. These machines, along with other equipment like large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, and grinding machines, work in harmony to provide high – quality precision parts.

GreatLight CNC Machining Factory adheres to strict ISO quality standards, having obtained ISO 9001:2015 certification. This ensures that every part machined on the CNC vertical gantry milling machines meets the highest quality requirements. Whether it’s for aerospace, automotive, or humanoid robot applications, the factory has proven its ability to deliver precision parts with high accuracy and reliability.

Conclusion

In summary, the CNC vertical gantry milling machine is a cornerstone of modern precision manufacturing. Its precision, versatility, and efficiency make it an indispensable tool for producing large, complex, and high – quality parts. GreatLight CNC Machining Factory, with its advanced equipment, experienced workforce, and strict quality control, is well – positioned to leverage the capabilities of these machines to provide excellent precision parts machining and customization services. So, if you are in need of custom precision parts, choosing GreatLight CNC Machining Factory means choosing a reliable partner for high – end manufacturing. What Is The CNC Vertical Gantry Milling Machine? The answer lies in its remarkable functions and the top – notch machining services provided by manufacturers like GreatLight CNC Machining Factory.

Frequently Asked Questions (FAQ)

Q1: What types of materials can a CNC vertical gantry milling machine process?

A: These machines can process a wide variety of materials, including metals such as aluminum, steel, titanium, and alloys. They can also handle non – metallic materials like plastics and composites.

Q2: How accurate can a CNC vertical gantry milling machine be?

A: High – end CNC vertical gantry milling machines can achieve extremely high accuracy, often up to ±0.001mm or even better, depending on the machine’s specifications and the complexity of the machining task.

Q3: Can GreatLight CNC Machining Factory handle large – scale production orders with its gantry milling machines?

A: Yes. GreatLight CNC Machining Factory is well – equipped to handle large – scale production orders. With its advanced gantry milling machines, experienced operators, and efficient production processes, it can ensure consistent quality and timely delivery for high – volume orders.

Q4: What is the advantage of using a CNC – controlled gantry milling machine compared to traditional milling machines?

A: CNC – controlled gantry milling machines offer higher precision, better repeatability, and greater automation. They can execute complex machining tasks with minimal human intervention, reducing the risk of errors and increasing production efficiency. You can learn more about GreatLight Metal on their LinkedIn page.