Precision Machining with GreatLight CNC Machining Factory

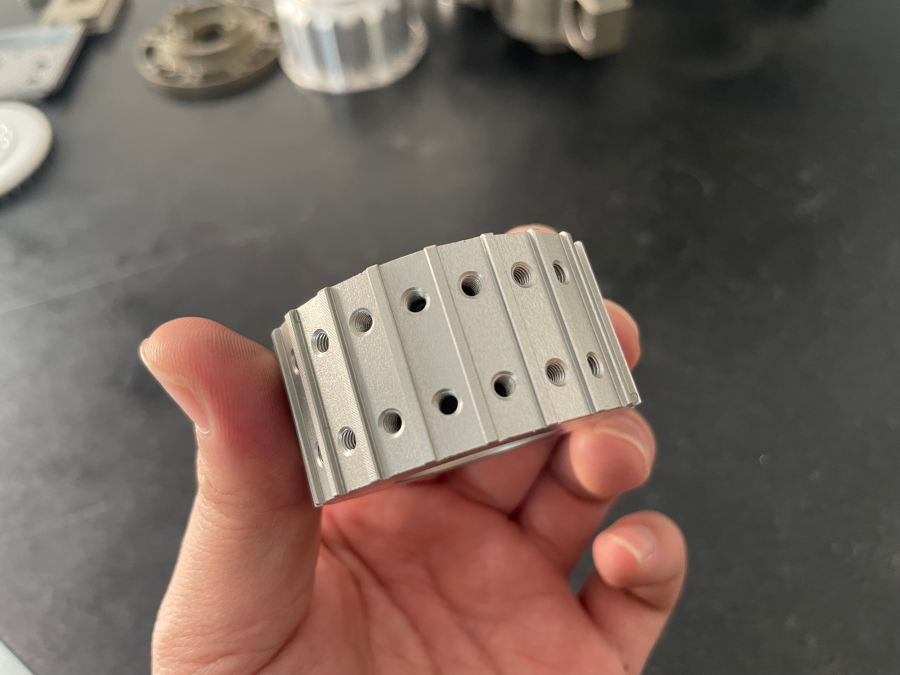

In the realm of precision parts machining and customization, finding a reliable partner is crucial for success. GreatLight CNC Machining Factory, established in 2011, has positioned itself as a leader in the industry, offering advanced five-axis CNC machining services tailored to meet the unique needs of various applications.

Advanced Technology and Equipment

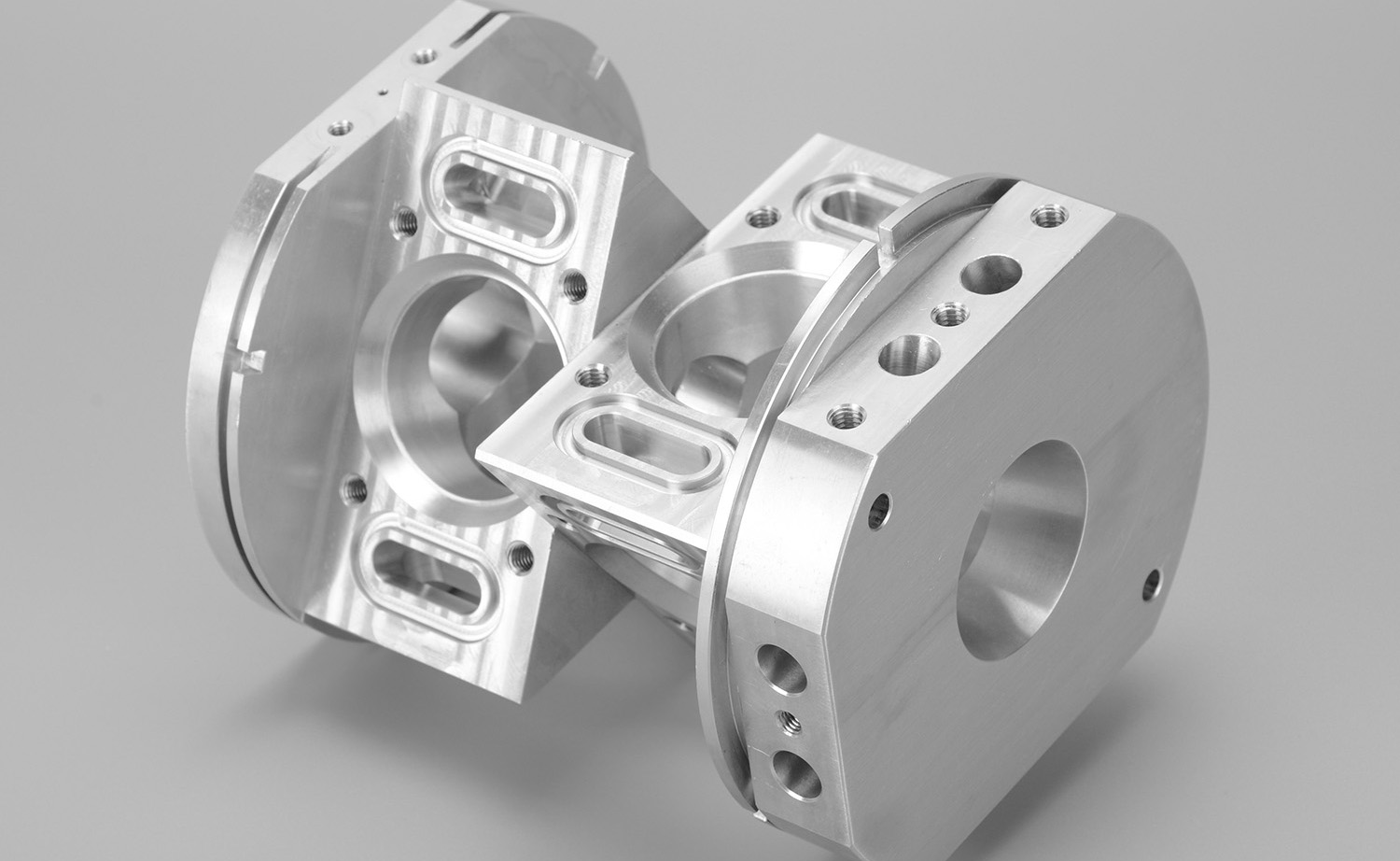

GreatLight CNC Machining Factory boasts a comprehensive suite of equipment, including 127 pieces of precision machinery. This includes high-precision five-axis, four-axis, and three-axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, and 3D printers. This extensive range of machinery ensures that we can handle even the most complex machining tasks with precision and efficiency.

Comprehensive Services

Our services cover a wide array of precision manufacturing needs:

Precision CNC Machining: Three-axis, four-axis, and five-axis machining services.

CNC Milling Services: For intricate designs and complex geometries.

Die Casting and Metal Die Casting Processing: For high-volume production needs.

Vacuum Casting Customization: For lightweight and complex parts.

Sheet Metal Processing Customization: For various industrial applications.

3D Printing: Including stainless steel, aluminum alloy, titanium alloy, and mold steel.

Rapid Prototyping: Nearly a hundred processing services and comprehensive solutions.

One-Stop Surface Post-Processing Services: Ensuring the final product meets the highest standards.

Quality Assurance

GreatLight CNC Machining Factory adheres strictly to ISO quality standards, holding ISO 9001:2015 certification. Our in-house precision measurement and testing equipment ensure that all materials and parts meet your specifications. We are committed to delivering high-quality products with precision as high as ±0.001mm.

Industry Experience and Expertise

With over a decade of experience in precision prototype model processing, GreatLight CNC Machining Factory has serviced various industries, including automotive, aerospace, medical hardware, and humanoid robots. Our team of experts is dedicated to providing solutions tailored to your specific needs.

Why Choose GreatLight CNC Machining Factory?

Advanced Technology: State-of-the-art equipment for precision machining.

Comprehensive Services: A wide range of services to meet all your manufacturing needs.

Quality Assurance: ISO 9001:2015 certified, ensuring the highest quality standards.

Industry Experience: Over a decade of experience in precision manufacturing.

Customer Support: Excellent after-sales service, including free rework for quality issues and full refunds if rework is unsatisfactory.

Conclusion

GreatLight CNC Machining Factory is your ideal partner for custom precision parts machining. With our advanced technology, comprehensive services, and commitment to quality, we ensure that your manufacturing needs are met with precision and reliability.

For more information about our services and how we can assist you in your precision manufacturing needs, please refer to our precision 5-axis CNC machining services.

Frequently Asked Questions (FAQ)

Q: What types of materials can GreatLight CNC Machining Factory process?

A: We can process a wide variety of materials, including metals like aluminum, stainless steel, titanium, and various alloys, as well as plastics and composites.

Q: What is the maximum size of parts that GreatLight CNC Machining Factory can machine?

A: Our maximum processing size is 4000 mm, allowing us to handle large components.

Q: Does GreatLight CNC Machining Factory offer design services?

A: While we specialize in machining and manufacturing, we can collaborate with your design team to ensure that your parts are manufactured to your exact specifications.

Q: How long does it take to produce a prototype?

A: Depending on the complexity of the part, we can produce prototypes within days using our advanced CNC machining technology.

Q: What kind of post-processing services does GreatLight CNC Machining Factory offer?

A: We offer a full range of surface post-processing services, including grinding, polishing, anodizing, and painting, to ensure the final product meets your aesthetic and functional requirements.

Q: Is GreatLight CNC Machining Factory ISO certified?

A: Yes, we are ISO 9001:2015 certified, ensuring our processes meet international quality standards.

Q: Can GreatLight CNC Machining Factory handle small batch production?

A: Absolutely, we are equipped to handle both small batch and large-scale production runs, ensuring consistency and quality across all batches.

Q: What industries does GreatLight CNC Machining Factory serve?

A: We serve a diverse range of industries, including automotive, aerospace, medical hardware, humanoid robots, and high-end consumer electronics.

For more information and case studies about GreatLight CNC Machining Factory, please refer to our LinkedIn page.