For manufacturing engineers, production managers, and business owners across the United States looking to enhance their precision machining capabilities, the question of where to buy CNC grinding machines is a critical investment decision. This equipment represents the pinnacle of precision for achieving micron-level tolerances, superior surface finishes, and the machining of ultra-hard materials. While purchasing a machine is one path, a comprehensive analysis often reveals that partnering with an expert machining service provider can be a more strategic and cost-effective solution for many operations.

This article will navigate the landscape of CNC grinding machine procurement in the US and present a compelling case for why outsourcing to a specialized, certified manufacturer like GreatLight CNC Machining Factory often yields greater ROI, flexibility, and guaranteed quality.

H2: The US Market for CNC Grinding Machines: A Buyer’s Overview

The US market offers several avenues for procuring high-end CNC grinding machines, primarily through direct manufacturers and specialized distributors.

H3: Major OEMs (Original Equipment Manufacturers)

These are the industry leaders who design and build the machines. Sourcing directly from them guarantees cutting-edge technology and direct manufacturer support.

United Grinding Group: A powerhouse offering brands like MÄGERLE (profile and surface grinding), BLOHM (creep-feed and surface grinding), STUDER (universal cylindrical grinding), and WALTER (tool grinding).

Haas Multigrind®: Known for their affordable CNC technology, Haas offers versatile grinding solutions suitable for toolroom and production environments.

Okamoto Corporation: A global leader in precision surface, profile, and cylindrical grinding machines, renowned for their durability and accuracy.

Toyoda: Excellent for high-production cylindrical and centerless grinding applications, particularly in automotive sectors.

ANCA: The world leader in CNC tool and cutter grinders.

H3: Authorized Distributors and Dealers

For many OEMs, distributors are the primary sales and service channel. Companies like Gosiger, Hartwig, Methods Machine Tools, and Ellison Technologies provide regional sales, application engineering, training, and crucially, local service and parts support.

H4: Key Considerations Before You Buy:

Application: Identify the primary need—cylindrical, surface, centerless, tool & cutter, or creep-feed grinding.

Budget: New machines range from ~$150,000 to over $1 million. Don’t forget the costs of installation, tooling, fixturing, and operator training.

Technical Support: The value of a responsive, knowledgeable local service team cannot be overstated for minimizing downtime.

Lead Time: New machine delivery can take 6-12 months or more.

H2: The Hidden Calculus: Total Cost of Ownership vs. Strategic Outsourcing

Purchasing a CNC grinding machine is a significant capital expenditure. The strategic decision should extend beyond the purchase price to the Total Cost of Ownership (TCO):

Capital Outlay: The multi-hundred-thousand-dollar machine purchase.

Facility & Infrastructure: Requires substantial floor space, specialized power (3-phase), high-quality air supply, and possibly coolant chilling systems.

Personnel: Hiring and retaining a skilled CNC grinding programmer/operator commands a high salary. Continuous training is needed to keep up with technology.

Tooling & Fixturing: High-precision diamond/CBN wheels, dressers, and custom workholding can cost tens of thousands.

Maintenance & Downtime: Regular preventive maintenance, unexpected breakdowns, and the cost of production halts.

Technology Obsolescence: Grinding technology advances; the machine may become less competitive over its 10-15 year lifespan.

For many companies, especially those with fluctuating demand, prototype projects, or highly complex parts, this TCO makes outsourcing to a dedicated precision machining partner a superior financial and operational strategy.

H2: GreatLight CNC Machining Factory: Your Strategic Outsourcing Partner for Precision Grinding

Instead of navigating the complexities of machine procurement, training, and process validation, you can immediately leverage world-class CNC grinding capabilities through a partnership with GreatLight CNC Machining Factory. Our model is built to eliminate your pain points and deliver guaranteed results.

H3: Why Outsource Your Precision Grinding to GreatLight?

Zero-Capital-Access to Advanced Technology: We have already made the multi-million-dollar investment in a comprehensive suite of precision grinding equipment, including surface, cylindrical, and centerless grinders, integrated within our full-process chain. You pay only for the parts you need.

Instant Expertise: Our engineering team possesses decades of collective experience in material science, grinding wheel selection, fixturing design, and programming for optimal surface integrity and dimensional stability.

Integrated Quality Assurance: Every grinding process is backed by our in-house metrology lab (with CMMs, profilometers, optical comparators). Our ISO 9001:2015 certification ensures a systematic, documented quality process from quote to delivery.

Full-Process Solution: Grinding is rarely a standalone operation. At GreatLight, it is seamlessly integrated with our 5-axis CNC machining, turning, milling, and EDM capabilities. We can machine the near-net-shape part and perform the final precision grinding, all under one roof, ensuring accountability and streamlined logistics.

Scalability & Flexibility: Ramp production up or down without worrying about machine utilization rates or idle operator costs. We handle both low-volume, high-complexity prototypes and sustained production runs.

H3: Our Certifications: The Foundation of Trust

Our processes are not just based on experience; they are underpinned by internationally recognized standards that validate our reliability:

ISO 9001:2015: The backbone of our quality management system.

IATF 16949: Our commitment to the stringent quality and traceability standards of the automotive industry.

ISO 13485: Governance for medical device component manufacturing, where material integrity and documentation are paramount.

ISO 27001: Ensuring the security of your sensitive design data and intellectual property.

H2: Conclusion: Invest in Outcomes, Not Just Machinery

The question of where to buy CNC grinding machines in the US leads to a clear marketplace of reputable OEMs and distributors. However, the more profound strategic question is: Should you buy?

For businesses focused on their core product innovation and market growth, the capital, time, and expertise required to build and maintain a world-class grinding operation in-house are immense. Partnering with a certified, full-service expert like GreatLight CNC Machining Factory converts a fixed capital cost into a variable, value-driven operational expense. It provides immediate access to precision, scalability, and guaranteed quality, freeing your resources to focus on what you do best.

In precision manufacturing, the ultimate goal is not to own the machine, but to reliably obtain perfect parts. Let GreatLight be the extension of your manufacturing floor, where our machines and mastery become your competitive advantage.

H2: Frequently Asked Questions (FAQ)

H3: Q1: What types of grinding processes can GreatLight handle?

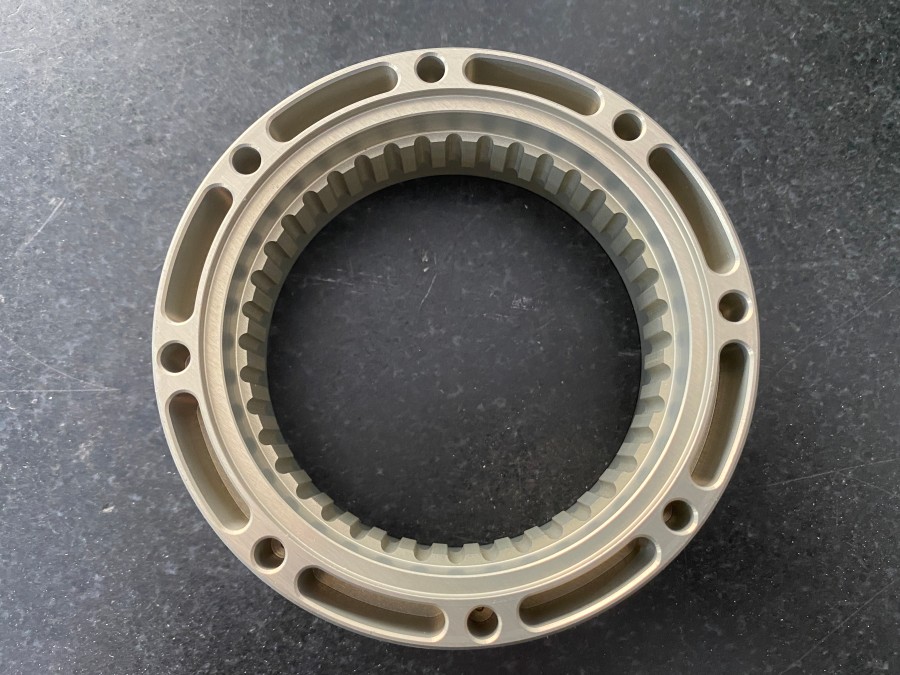

A: We provide comprehensive grinding services including Precision Surface Grinding for flatness and parallelism, Cylindrical Grinding (OD/ID) for concentricity and diameter control, and Centerless Grinding for high-volume, high-precision bar work. We select the optimal process based on your part geometry and tolerances.

H3: Q2: My part requires milling, heat treatment, and then grinding. Can you manage this entire process?

A: Absolutely. This is our core strength. We excel at full-process manufacturing. We can CNC machine the part from raw material, coordinate with trusted partners for heat treatment (or advise on processes), and then perform the final precision grinding and finishing—managing the entire workflow, ensuring seamless transitions and total quality control.

H3: Q3: What materials and tolerances can you achieve with grinding?

A: We grind a vast range of materials: tool steels (D2, A2, H13), stainless steels, aluminum alloys, carbides, and engineering ceramics. We routinely hold tolerances to ±0.0002″ (0.005mm) and achieve surface finishes of 8 Ra µin (0.2 µm Ra) or better, depending on the material and part configuration.

H3: Q4: How do you ensure consistency for larger production runs?

A: Consistency is guaranteed through our process control. We use proven, documented grinding parameters, in-process gauging where applicable, and first-article/in-process/final inspections using calibrated, high-precision measurement equipment. Our ISO and IATF certifications mandate this rigorous approach to repeatability.

H3: Q5: Why choose GreatLight over a local US machine shop for grinding?

A: While local shops offer proximity, GreatLight provides a unique combination of world-class technical capability, integrated full-service processing, and cost competitiveness due to our specialized focus and scale. Our ISO 13485 and IATF 16949 certifications also demonstrate a level of systematic quality management that matches the requirements of the most demanding industries. Connect with our team on LinkedIn to see our ongoing projects and industry engagement.