For engineers, procurement teams, and manufacturing leaders navigating the world of custom precision parts, one question often arises: What Type Of Plasma Cutter Is Best For CNC Machines? As CNC machining becomes increasingly integral to industries ranging from automotive to aerospace and medical devices, selecting the right plasma cutter can make or break the efficiency, precision, and cost-effectiveness of your production line. With the right match, you can achieve clean, accurate cuts on a wide range of materials, reduce waste, and streamline your workflow—critical factors in today’s competitive manufacturing landscape.

What Type Of Plasma Cutter Is Best For CNC Machines?

The “best” plasma cutter for your CNC machine depends on your specific material needs, precision requirements, production volume, and long-term operational goals. Below is a breakdown of the most common types, their strengths, and ideal use cases, paired with insights from how industry leaders like GreatLight CNC Machining Factory leverage these tools:

1. High-Definition (HD) Plasma Cutters: The Gold Standard for Precision

High-definition plasma cutters use a constricted arc, higher gas pressures, and advanced torch design to produce narrower kerfs (the width of the cut), smoother edge finishes, and tighter tolerances compared to standard plasma cutters. This makes them ideal for thin to medium-thickness conductive materials (0.5–25mm for mild steel, aluminum, or stainless steel) where precision is non-negotiable.

Ideal For: Medical device components (like surgical instrument frames), automotive precision parts (engine brackets, sensor housings), and high-end consumer electronics enclosures. GreatLight CNC Machining Factory relies heavily on HD plasma cutters for its sheet metal processing services, particularly for clients requiring parts that need minimal post-processing (e.g., bending, welding) to meet final specifications. The precision of HD plasma cuts reduces rework time by up to 30% for these high-tolerance projects.

2. CNC-Optimized Plasma Cutters with Integrated Height Control

CNC-specific plasma cutters with real-time height adjustment use sensors to maintain a consistent distance between the torch and material surface, even if the sheet is uneven or warped. This eliminates common issues like incomplete cuts, overheating, or inconsistent edge quality that can occur with fixed-height torches.

Ideal For: Industrial automation parts (robot base frames, conveyor system components) and heavy-duty sheet metal projects where material flatness varies. GreatLight integrates these systems with its 3-axis and 4-axis CNC machines to ensure uniform cuts across large or irregularly shaped sheets, a critical capability for clients in the aerospace sector needing lightweight structural parts.

3. Dual-Process Plasma Cutters (Plasma + Oxy-Fuel): Versatility for Mixed Materials

For projects that require cutting both thin non-ferrous metals and thick ferrous metals, dual-process systems combine plasma cutting (for conductive materials like aluminum or copper) with oxy-fuel cutting (for mild steel up to 150mm thick). This eliminates the need for multiple machines, reducing setup time and floor space.

Ideal For: Construction equipment manufacturers, automotive chassis suppliers, and clients with mixed material batches. GreatLight uses dual-process cutters to serve clients needing integrated solutions for both thin aluminum brackets and thick steel structural components, streamlining their supply chain by handling all cutting needs in one facility.

4. Portable CNC Plasma Cutters: For Small-Scale or On-Site Projects

Compact, lightweight, and easy to transport, portable CNC plasma cutters are designed for low-volume production, prototyping, or on-site repair work. While they offer less precision than HD or automated models, they provide flexibility for clients who need parts manufactured outside a traditional factory setting.

Ideal For: Startups, R&D teams testing new designs, or field service companies needing emergency part replacements. GreatLight offers portable plasma cutting as part of its rapid prototyping services, allowing clients to iterate on designs quickly without committing to large-scale production runs.

5. Automated CNC Plasma Cutters with Nesting Software

These systems integrate advanced nesting software that optimizes part placement on raw material sheets, minimizing waste by arranging as many parts as possible in a single cut. Automated loading/unloading features further reduce manual labor, making them ideal for high-volume production.

Ideal For: Mass production of automotive components, electrical enclosures, or consumer appliance parts. GreatLight uses nesting software to reduce material waste by up to 15% for high-volume orders, passing these cost savings directly to clients while maintaining strict quality standards.

To help you compare these options at a glance, here’s a quick reference table:

| Plasma Cutter Type | Ideal Material Thickness | Precision Level | Best For |

|---|---|---|---|

| High-Definition (HD) Plasma | 0.5–25mm (metals) | ±0.005–0.01mm | Medical parts, automotive precision components |

| CNC-Optimized with Height Control | 1–30mm (metals) | ±0.01–0.02mm | Uneven sheet metal, industrial automation parts |

| Dual-Process (Plasma + Oxy-Fuel) | 0.5–150mm (ferrous metals) | ±0.02–0.05mm | Mixed thickness projects, heavy-duty industrial parts |

| Portable CNC Plasma | 0.5–12mm (metals) | ±0.02–0.03mm | Prototyping, on-site repairs, small runs |

| Automated with Nesting Software | 0.5–30mm (metals) | ±0.01–0.02mm | Mass production, cost-efficient high-volume orders |

Key Factors to Consider When Matching Plasma Cutters to CNC Machines

Beyond the type of plasma cutter, several critical factors will influence your decision:

Material Type and Conductivity

Plasma cutters only work on conductive materials (metals). For non-conductive materials like plastic, you’ll need alternative processes like CNC milling or 3D printing. GreatLight offers a full suite of manufacturing services, so if your project combines metal and plastic components, we can integrate plasma cutting with other processes to deliver a complete solution.

Precision and Tolerance Requirements

If your parts require tolerances of ±0.001mm, an HD plasma cutter is the best choice. For less critical applications, a standard CNC-optimized model may suffice. GreatLight’s quality control team uses precision measurement equipment to verify tolerances at every stage, ensuring compliance with ISO 9001:2015 and industry-specific standards like IATF 16949 (automotive) and ISO 13485 (medical).

Production Volume and Scalability

Portable cutters work well for small runs, but automated systems with nesting software are more cost-effective for mass production. GreatLight’s three wholly-owned manufacturing plants can scale production from a single prototype to 10,000+ parts, adjusting plasma cutting technology to match your volume needs.

Integration with Existing CNC Systems

Your plasma cutter must communicate seamlessly with your CNC controller to avoid errors or workflow delays. GreatLight’s in-house engineering team has experience integrating a wide range of plasma systems with 3-axis, 4-axis, and 5-axis CNC machines, ensuring a smooth transition for clients upgrading their production lines.

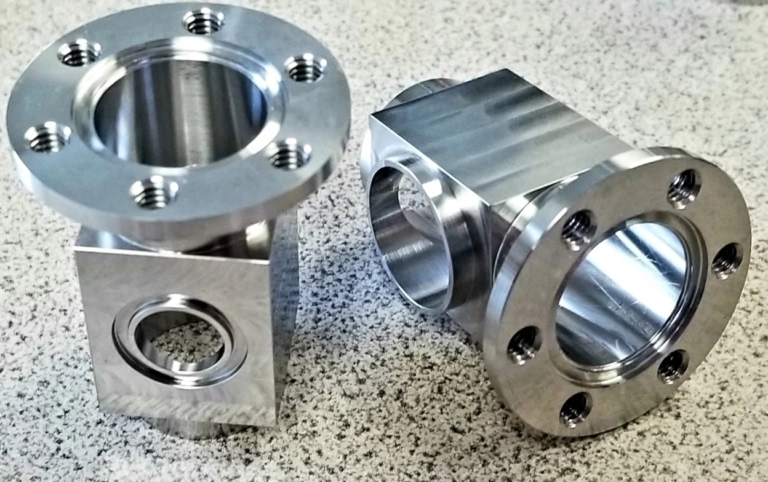

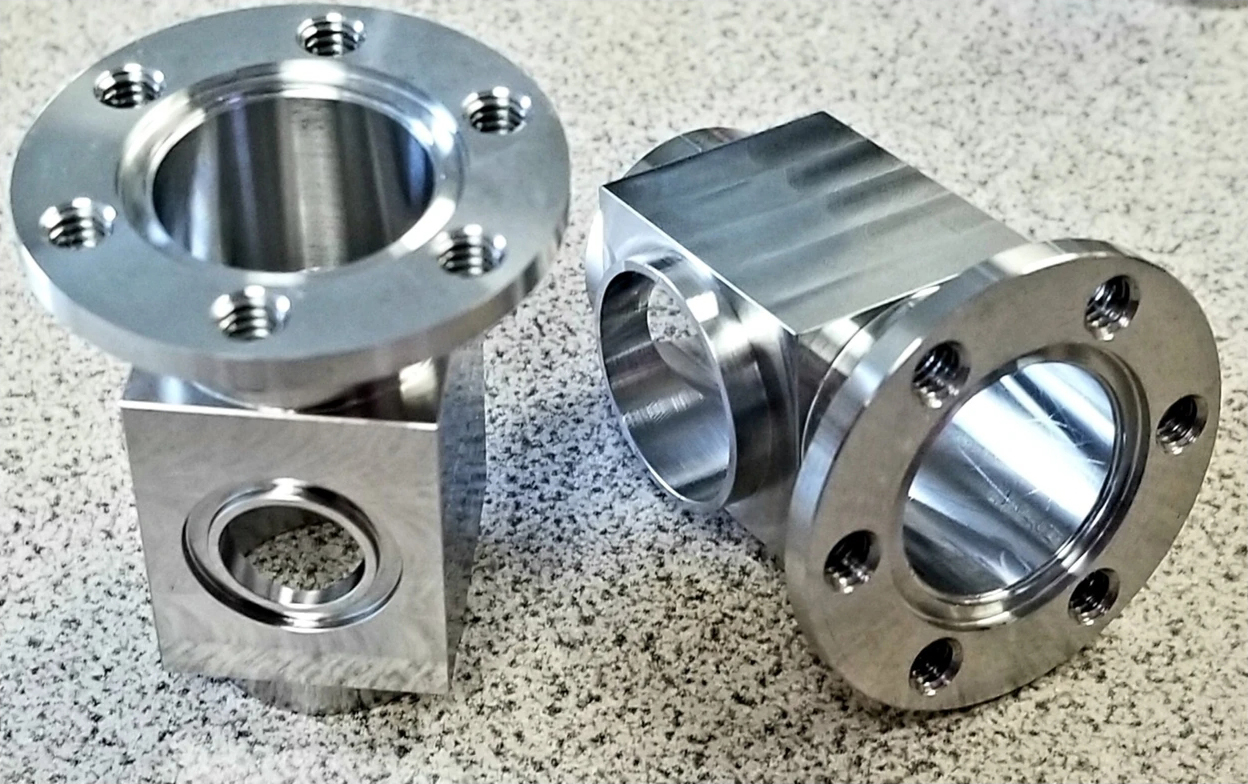

How GreatLight CNC Machining Factory Leverages CNC Plasma Cutting for Custom Precision Parts

Founded in 2011 and located in Dongguan’s Chang’an District (China’s “Hardware and Mould Capital”), GreatLight is a leading provider of one-stop precision manufacturing solutions. With a 7600 sqm facility, 150 employees, and 127 pieces of precision equipment—including state-of-the-art plasma cutters integrated with CNC systems—GreatLight has the capacity to handle even the most complex plasma cutting projects.

For example, a new energy vehicle client approached GreatLight needing custom aluminum battery tray components. The project required high precision (±0.005mm tolerance) and efficient cutting of thin aluminum sheets to minimize weight. GreatLight used an HD plasma cutter with integrated height control, paired with nesting software to reduce material waste by 12%. The team delivered the parts 2 days ahead of schedule, and the client reported a 25% reduction in assembly time due to the clean, consistent cuts.

GreatLight’s commitment to quality is backed by industry-leading certifications (ISO 9001:2015, IATF 16949, ISO 13485) and a robust after-sales guarantee: free rework for quality issues, or a full refund if rework is still unsatisfactory. Whether you need a single prototype or mass-produced parts, GreatLight’s expertise in CNC plasma cutting and integrated manufacturing ensures you get the right solution for your needs.

Conclusion

When asking, What Type Of Plasma Cutter Is Best For CNC Machines?, the answer ultimately depends on your specific material needs, precision requirements, production volume, and long-term goals. Whether you need the high precision of HD plasma for medical parts, the versatility of dual-process systems for mixed materials, or the efficiency of automated nesting for mass production, selecting the right tool is critical to unlocking success in your manufacturing projects. GreatLight CNC Machining Factory, with its decade of experience, comprehensive equipment lineup, and commitment to quality, is your ideal partner for navigating these choices. From initial design to final post-processing, GreatLight provides one-stop solutions that leverage the right plasma cutting technology to meet your unique needs, ensuring you get precision parts on time, within budget, and to the highest standards.

Frequently Asked Questions (FAQ)

1. Can plasma cutters on CNC machines handle non-metal materials like plastic?

Plasma cutters are designed exclusively for conductive materials (metals like steel, aluminum, or copper). For plastic parts, GreatLight offers alternative technologies like CNC milling, 3D printing (SLA/SLS/SLM), or vacuum casting. We can also provide integrated solutions for projects combining metal and plastic components.

2. What is the maximum material thickness GreatLight can cut with CNC plasma?

GreatLight’s dual-process plasma cutters can handle mild steel up to 150mm thick, while our HD plasma cutters excel at thin to medium metals (0.5–25mm). For materials beyond plasma capabilities, we offer oxy-fuel cutting or CNC milling as alternatives.

3. How does GreatLight ensure consistent precision with CNC plasma cutting?

GreatLight uses CNC plasma cutters with real-time height control, alongside our ISO 9001:2015 certified quality management system. We conduct in-process inspections using precision measurement tools (like coordinate measuring machines) to verify tolerances up to ±0.001mm. If quality issues arise, we offer free rework or a full refund if rework does not meet your expectations.

4. Can GreatLight adapt to custom nesting software for my project?

Yes. GreatLight uses advanced nesting software to optimize material usage, and our engineering team can adapt to custom nesting specifications provided by clients. This ensures minimal waste and maximum efficiency, especially for high-volume orders.

5. What industries does GreatLight serve with CNC plasma cutting?

GreatLight uses CNC plasma cutting to serve a wide range of industries, including automotive (engine components, chassis parts), medical (surgical instrument frames, device enclosures), industrial automation (robot base parts, conveyor systems), aerospace (lightweight structural parts), and construction equipment manufacturing.

6. Does GreatLight offer post-processing services for plasma-cut parts?

Absolutely. GreatLight provides one-stop post-processing services for plasma-cut parts, including deburring, painting, powder coating, anodizing, and welding. This ensures your parts are ready for assembly or final use without needing to work with multiple suppliers.