Understanding CNC Machine Operator Salaries: A Comprehensive Guide for Industry Professionals

In the precision manufacturing sector, the role of a CNC machine operator is fundamental. As the bridge between sophisticated programming and the physical creation of high-tolerance parts, these skilled professionals are vital to the success of operations at facilities like GreatLight CNC Machining Factory. The question of salary is multifaceted, influenced by geography, experience, skill level, industry, and the complexity of the machinery operated. This analysis provides a detailed breakdown to help clients and aspiring professionals understand the compensation landscape.

Key Factors Influencing CNC Operator Salaries

Compensation is rarely a one-size-fits-all figure. It is dynamically shaped by several core variables:

Geographic Location: Economic conditions and cost of living create significant variance. Operators in manufacturing hubs in Germany, the United States, or coastal China typically earn more than those in regions with lower industrial concentration.

Experience and Skill Level: Entry-level operators naturally start at a base wage. Those with years of experience, especially with proven ability to manage setups, perform in-process inspections, and troubleshoot complex issues, command premium pay.

Machine Complexity: Operating a basic 3-axis mill differs greatly from programming and running a sophisticated 5-axis CNC machining center. Proficiency with multi-axis machines, mill-turn centers, or Swiss-type lathes is a high-value skill.

Industry Sector: Aerospace, medical device, and automotive industries, where precision and documentation are critical (often requiring adherence to standards like IATF 16949 or ISO 13485), generally offer higher compensation than sectors with less stringent tolerances.

Certifications and Training: Formal certifications from technical institutions or specific machine tool brands enhance an operator’s qualifications and earning potential.

Company Size and Capability: A full-service, technologically advanced manufacturer like GreatLight CNC Machining Factory, which invests in continuous training and handles high-value projects, often structures compensation to attract and retain top talent capable of meeting ±0.001mm tolerances.

Global and Regional Salary Breakdown

While figures fluctuate, the following ranges offer a realistic overview (annual gross salaries, converted to USD for comparison where applicable).

1. North America (United States & Canada)

Entry-Level / General Operator: $35,000 – $45,000

Experienced Operator/Setup Person: $45,000 – $60,000

Senior Operator/Programmer (Multi-Axis): $60,000 – $80,000+

Note: Wages are often hourly, with overtime significantly boosting total compensation. Regions like the Midwest (industrial heartland) and coasts offer higher rates.

2. Western Europe (Germany, Switzerland, Italy)

Entry-Level: €30,000 – €38,000

Experienced: €38,000 – €50,000

Senior/Specialist: €50,000 – €65,000+

Strong vocational systems and high manufacturing standards support robust wages.

3. China (Mainland, with focus on industrial clusters like Dongguan/Shenzhen)

Entry-Level: ¥60,000 – ¥90,000 RMB (approx. $8,300 – $12,500)

Skilled Operator (3-5 Axis): ¥90,000 – ¥150,000 RMB (approx. $12,500 – $20,800)

Advanced Technician/Programmer: ¥150,000 – ¥250,000+ RMB (approx. $20,800 – $34,700+)

In premium manufacturers focusing on export-quality precision parts—such as those in Dongguan’s Chang’an district, home to GreatLight Metal—salaries for skilled operators are highly competitive, reflecting the technical demands and value of the output.

The Value of Specialization: Why 5-Axis and Precision Command Premiums

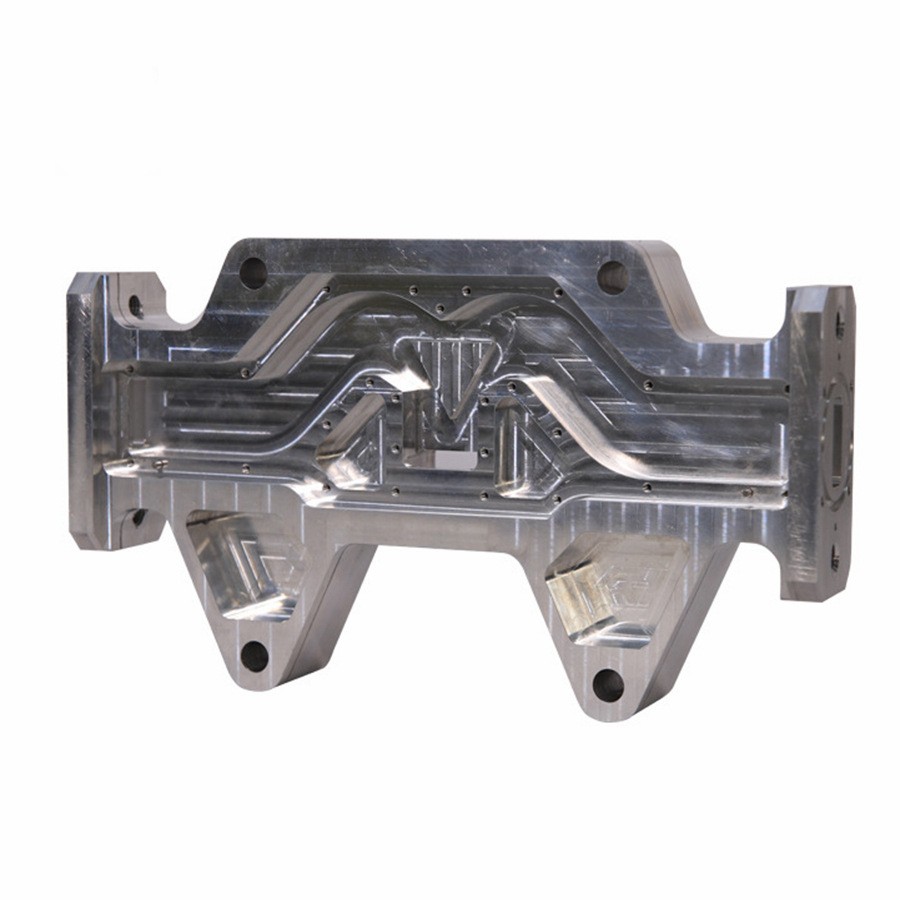

The most significant salary differentiation comes from technical specialization. An operator capable of handling precision 5-axis CNC machining services is not merely running a machine; they are managing a complex manufacturing process. Their responsibilities encompass:

Interpreting intricate 3D models and GD&T drawings.

Setting up and calibrating machines for micron-level accuracy.

Performing first-article inspections using advanced metrology tools.

Optimizing tool paths and cutting parameters for efficiency and surface finish.

Ensuring consistent quality in batches, crucial for automotive or aerospace clients.

This skillset is scarce and highly valued. Manufacturers investing in this technology, like GreatLight CNC Machining Factory, understand that their competitive edge lies in both their equipment and the people who master it. Consequently, they are motivated to offer superior compensation and career progression paths to secure such talent.

Beyond Base Salary: The Total Compensation Package

When evaluating a role, consider the entire package:

Benefits: Health insurance, retirement contributions, and paid leave.

Overtime & Shift Differentials: Significant earning potential often comes from overtime pay, especially during project crunches. Night shifts typically carry a premium.

Bonus Structures: Performance-based or profit-sharing bonuses.

Continuous Training: Investment in upskilling (e.g., learning new CAM software, metrology) is a non-monetary benefit with long-term career value.

Conclusion

The salary for a CNC machine operator is a direct reflection of their technical proficiency, the complexity of their work, and the standards of the industry they serve. From foundational 3-axis operations to the advanced realm of 5-axis CNC machining, compensation scales with responsibility and skill. For clients seeking manufacturing partners, understanding this landscape is insightful: a factory that invests fairly in its workforce is often one that maintains high morale, low turnover, and consistently excellent output quality. Facilities like GreatLight CNC Machining Factory, which build their reputation on precision and reliability, inherently recognize that their skilled operators are the cornerstone of their service delivery, a principle reflected in their approach to talent management and compensation.

Frequently Asked Questions (FAQ)

Q1: What is the career progression path for a CNC machine operator?

A: A typical path progresses from Trainee/Operator to Setup Operator, then to CNC Programmer (often using CAM software), and potentially to Manufacturing Engineer or Shop Floor Supervisor. Specializing in areas like CMM operation, tooling design, or process optimization also offers advanced career lanes.

Q2: Are CNC programmers paid more than operators?

A: Generally, yes. A CNC programmer, who creates the G-code instructions from CAD models, requires deeper knowledge of machining principles, materials, and software. This role typically commands a higher salary than a pure operator role, though many skilled personnel blend both responsibilities.

Q3: How important are formal certifications for getting a higher salary?

A: While hands-on experience is paramount, certifications from bodies like the National Institute for Metalworking Skills (NIMS) or specific machine tool builders (e.g., Haas, DMG MORI) provide formal validation of skills. They can be decisive in hiring decisions and justify higher starting pay or promotions, especially in larger corporations or certified shops (ISO 9001, etc.).

Q4: Does working in a certified factory (like ISO 9001) affect operator pay?

A: Indirectly, yes. Factories maintaining stringent certifications like ISO 9001:2015 or IATF 16949 operate under rigorous procedural and quality standards. They require operators with a strong understanding of documentation, process control, and measurement. This higher level of accountability and required skill is often compensated at a premium compared to non-certified workshops.

Q5: What skills can an operator develop to increase their earning potential most effectively?

A: Focus on:

Mastering Multi-Axis Machining: Learn 4th and 5-axis programming and operation.

Precision Metrology: Become proficient with micrometers, calipers, CMMs, and optical comparators.

CAM Software Expertise: Gain deep proficiency in industry-standard software like Mastercam, Siemens NX, or Fusion 360.

Material Science Knowledge: Understand the machining characteristics of advanced alloys, titanium, and engineering plastics.

Quality System Literacy: Learn the documentation and mindset required for ISO or automotive standards.