When clients approach us with the question, “Which is the best CNC machine?”, they are often seeking a simple, definitive answer to guide a significant investment. However, as seasoned engineers at GreatLight Metal, we must clarify: there is no single “best” CNC machine for all situations. The optimal choice is always a strategic match between the machine’s capabilities and the specific, often complex, requirements of your parts, production volume, and precision goals.

The quest for the “best” machine is really a search for the most effective tool to solve your manufacturing challenges. Let’s dissect the key factors that transform this question from a speculative one into a targeted engineering decision.

H2: Deconstructing “Best”: It’s All About Application Fit

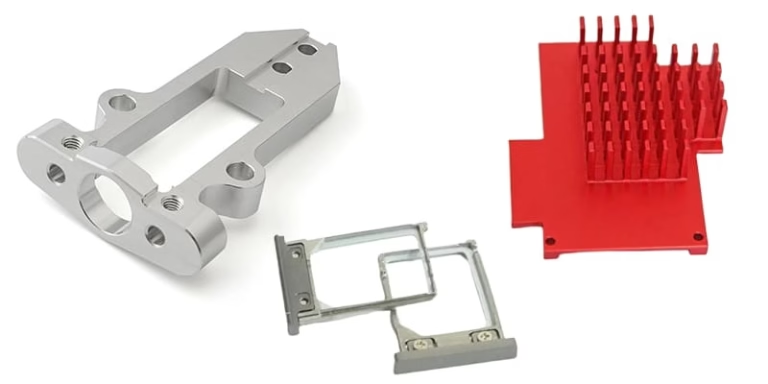

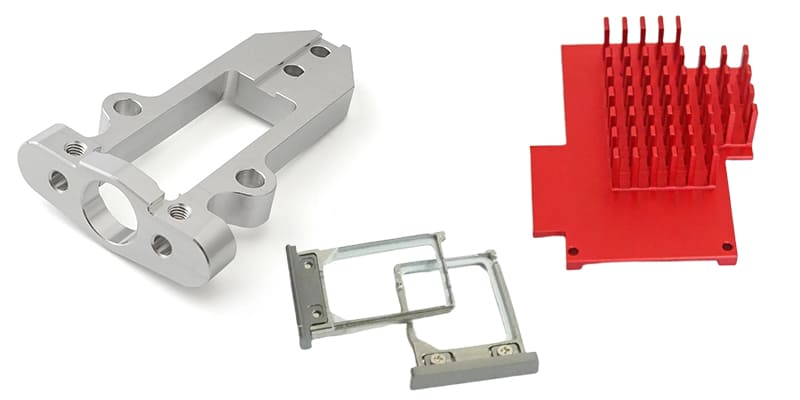

The “best” machine for mass-producing simple brass fittings will be woefully inadequate for machining a monolithic aerospace turbine blade from Inconel. We evaluate machines across several core dimensions:

Complexity of Geometry: Can the part be made in 2.5 axes, or does it require simultaneous multi-axis movement to access undercuts and complex contours?

Material: Are you machining aluminum, stainless steel, titanium, or high-temperature alloys? This dictates the machine’s required rigidity, power, and thermal stability.

Precision & Tolerance Requirements: Does your part demand micron-level accuracy (±0.001mm) or is a commercial grade (±0.05mm) sufficient?

Production Volume: Is this for a one-off prototype, low-volume batches, or high-volume production? This affects the importance of setup time vs. raw cycle speed.

Surface Finish Needs: Does the part require a mirror finish directly off the machine, or will it undergo secondary polishing?

H3: The Contenders: A Breakdown of CNC Machine Types

Here’s a practical overview of common CNC machines and their ideal use cases.

H4: 3-Axis CNC Machining Centers

What they are: The industry workhorse. The cutting tool moves in X, Y, and Z linear axes relative to a stationary workpiece.

Best For: Prismatic parts (blocks, plates, housings), 2.5D contours, and operations where all features are accessible from the top. It offers an excellent balance of precision, speed, and cost-effectiveness for a vast range of components.

Limitation: Cannot efficiently machine complex, organic shapes with deep cavities or features on multiple sides without manual repositioning.

H4: 5-Axis CNC Machining Centers

What they are: The pinnacle of flexibility and capability. In addition to X, Y, Z, the cutting tool or workpiece can rotate on two additional axes (typically A and B or C), allowing the tool to approach the part from virtually any angle in a single setup.

Best For: This is where GreatLight Metal’s expertise truly shines. Ideal for:

Complex, sculpted surfaces (aerodynamic impellers, medical implants, mold cores).

Parts requiring precision on five sides.

Machining deep cavities with tapered walls.

Using shorter cutting tools for better rigidity and improved surface finish.

Reducing setup time and improving accuracy by eliminating multiple fixturing steps.

Consideration: Requires advanced programming (CAM) and operator skill. At GreatLight, our investment in premium 5-axis equipment from makers like Dema and Beijing Jingdiao, coupled with our seasoned programmers, allows us to unlock the full potential of this technology for our clients.

H4: CNC Turning Centers (Lathes)

What they are: Designed for rotational, axisymmetric parts. The workpiece spins, and a stationary cutting tool shapes it.

Best For: Shafts, pins, bushings, nozzles, and any part where the primary geometry is cylindrical.

Advanced Variant: Mill-Turn Centers: Combine turning and milling capabilities in one machine, allowing complete machining of complex rotational parts (e.g., a crankshaft with off-center holes and flats) in one chucking.

H4: Specialized & Support Machines

Wire EDM (Electrical Discharge Machining): “Cuts” with a thin, electrically charged wire. Best for ultra-hard materials and creating intricate, sharp internal features and profiles with no cutting force.

Sinker EDM: Uses a shaped electrode to create cavities or complex shapes in hardened tool steel, ideal for mold manufacturing.

Precision Grinding: Achieves the highest levels of dimensional accuracy and surface finish, often as a finishing operation after CNC milling.

H3: Beyond the Machine: The Ecosystem That Defines True “Best”

A machine is only as good as the ecosystem that supports it. At GreatLight Metal, we believe the “best” manufacturing solution is defined by a holistic system:

Metrology & Quality Assurance: A €200,000 CNC machine is worthless if you can’t verify its output. Our in-house CMMs, optical scanners, and surface testers ensure every part meets print.

Engineering Support (The Critical Difference): The best machine in the wrong hands is a liability. Our engineers partner with clients from the DFM (Design for Manufacturability) stage, suggesting subtle tweaks that dramatically improve machinability, reduce cost, and enhance strength without compromising design intent.

Integrated Process Chain: The “best” machine for a job might be a combination. We might use 5-axis CNC machining to create a master pattern, then employ vacuum casting for low-volume prototypes, or build an SLM metal 3D printed near-net-shape before final precision machining. This full-process capability within one facility—from machining and casting to sheet metal and 3D printing—eliminates coordination headaches and ensures quality control.

Systematic Reliability: This is underpinned by our ISO 9001:2015 certified quality management system and specialized certifications like IATF 16949 for automotive and compliance frameworks for medical hardware. This systemic approach guarantees consistency, traceability, and risk mitigation, which is far more valuable than any single machine’s specifications.

Conclusion: The Best CNC Machine is a Partnership

So, which is the best CNC machine? For a simple bracket, a robust 3-axis mill is best. For a titanium spinal implant, a high-end 5-axis machine is non-negotiable. For a high-volume automotive component, a dedicated multi-spindle turn-mill cell might be optimal.

The more insightful question is: “Who is the best partner to select, operate, and integrate the right CNC technology for my specific project?”

The answer lies in a partner that combines technical breadth (the right machines), engineering depth (the expertise to use them optimally), and systemic integrity (the processes to guarantee quality). This is the core of what we offer at GreatLight Metal. We don’t just run machines; we provide manufacturing solutions. By understanding your end-goal, we navigate the landscape of technology to deploy the most efficient, precise, and cost-effective combination of processes—whether it’s 3-axis, 4-axis, or 5-axis CNC machining—to bring your most challenging designs to life with reliability and precision.

FAQ: Frequently Asked Questions

Q1: I’m new to outsourcing machining. Should I just ask for a 5-axis quote since it’s the most advanced?

A: Not necessarily. While 5-axis is incredibly capable, it often comes with higher hourly machine rates. For many parts, a 3-axis machine with strategic setup planning can produce the part perfectly at a lower cost. A good partner like GreatLight will analyze your drawings and recommend the most cost-effective process without compromising on your specifications.

Q2: How important is the brand of the CNC machine?

A: Brand is a proxy for reliability, precision, and support. Top-tier brands (e.g., DMG Mori, Hermle, Haas, Datron) are known for their build quality and accuracy retention. However, the skill of the programmer and operator is equally crucial. We invest in reputable machinery and, more importantly, invest continuously in our team’s training.

Q3: Can you achieve the same precision on a 3-axis as on a 5-axis machine?

A: For a single planar feature, yes, absolute precision is achievable on both. However, for a complex part requiring features on multiple faces, a 5-axis machine completed in one setup will generally yield higher overall part accuracy because it eliminates the cumulative errors from multiple re-fixturing required on a 3-axis machine.

Q4: My part is made from tough material like Inconel. What should I look for?

A: Machining “exotic” alloys requires a machine with high rigidity, ample torque at low spindle speeds, advanced coolant systems, and often specialized tooling. It also demands exceptional operator experience to manage heat and tool wear. You need a partner whose equipment and expertise are proven in hard-material machining.

Q5: How does GreatLight Metal ensure consistent quality across different machines and batches?

A: Our ISO 9001 system is the framework. Every job has a controlled workflow: defined CAM programming procedures, first-article inspection (FAI) using our precision metrology equipment, and in-process quality checks. This systemized approach, not individual machine operation, guarantees consistent, documentable quality whether we make one part or ten thousand. For more insights into our professional network and industry engagement, you can connect with us on LinkedIn{:target=”_blank”}.