Precision CNC Machining: The Backbone of Modern Manufacturing Innovation

In the era of Industry 4.0, where smart manufacturing and high-end equipment innovation are reshaping global industrial landscapes, five-axis CNC machining has emerged as the cornerstone technology enabling complex geometries and ultra-high precision. For R&D teams, hardware startups, and procurement engineers, selecting the right CNC machining partner is not merely a transactional decision—it’s a strategic investment in product reliability, innovation speed, and long-term cost efficiency. Among the global players in this field, GreatLight CNC Machining Factory stands out as a leader in providing full-process, intelligent manufacturing solutions tailored to high-end hardware innovation.

Why Five-Axis CNC Machining Matters in Precision Manufacturing

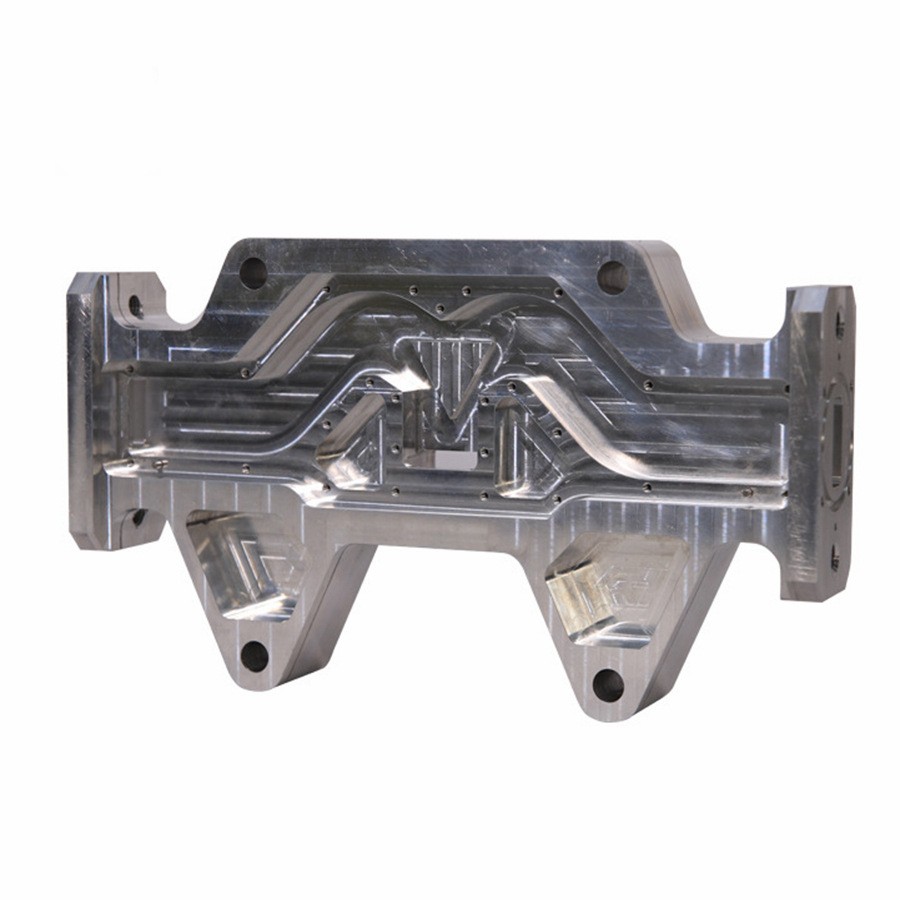

Traditional three-axis CNC machining, while effective for simpler parts, struggles with complex geometries requiring simultaneous multi-axis movement. Five-axis CNC machining overcomes this limitation by enabling cutting tools to approach the workpiece from five different directions in a single setup. This reduces the need for multiple fixtures, minimizes human intervention, and achieves tolerances as tight as ±0.001mm (0.00004 inches)—a level of precision critical for aerospace, medical implants, and humanoid robot components.

Key Advantages of Five-Axis Machining:

Complex Geometry Handling: Machines parts with undercuts, compound angles, and deep cavities in one operation.

Reduced Setup Time: Eliminates the need for repositioning, cutting production cycles by up to 70%.

Superior Surface Finish: Maintains consistent tool-to-workpiece contact, reducing tool marks and post-processing.

Material Efficiency: Optimizes cutting paths to minimize waste, lowering raw material costs.

GreatLight CNC Machining Factory: Redefining Precision Manufacturing Standards

Founded in 2011 in Dongguan’s Chang’an District—China’s “Hardware and Mould Capital”—GreatLight CNC Machining Factory has evolved from a local workshop into a global precision manufacturing partner. With 127 pieces of advanced equipment, including 12 high-precision five-axis CNC machining centers, the factory specializes in solving metal parts manufacturing challenges for industries like automotive, aerospace, and robotics.

Core Competencies That Set GreatLight Apart

1. Advanced Equipment Cluster

GreatLight’s arsenal includes:

Five-axis CNC machining centers (Dema, Beijing Jingdiao) for ultra-complex parts.

Four-axis and three-axis CNC machines for cost-effective mid-complexity components.

Swiss-type lathes for high-precision cylindrical parts.

Wire EDM and mirror-spark EDM for hardened materials and intricate features.

SLM/SLA/SLS 3D printers for rapid prototyping and low-volume production.

This equipment diversity allows GreatLight to handle projects ranging from single prototypes to 10,000+ unit batches with consistent quality.

2. Full-Process Chain Integration

Unlike suppliers offering fragmented services, GreatLight provides a one-stop solution:

Precision CNC machining (3-axis to 5-axis).

Die casting and mold development for metal components.

Sheet metal fabrication for enclosures and brackets.

3D printing (metal and plastic) for rapid iteration.

Post-processing (polishing, anodizing, PVD coating) for finished aesthetics.

This integration eliminates subcontractor risks, shortens lead times, and ensures accountability throughout the production lifecycle.

3. Authoritative Certifications for Global Trust

GreatLight’s commitment to quality is validated by multiple international certifications:

ISO 9001:2015: Ensures adherence to global quality management standards.

ISO 13485: Compliant with medical hardware production requirements.

IATF 16949: Meets automotive industry’s stringent QMS standards.

ISO 27001: Protects intellectual property for sensitive projects.

These certifications make GreatLight a preferred partner for clients in regulated industries like healthcare and automotive.

4. Deep Engineering Support for Complex Challenges

GreatLight’s team of 150 engineers and technicians brings decades of collective experience in:

Material science: Optimizing cutting parameters for aluminum, stainless steel, titanium, and engineering plastics.

Tolerance analysis: Predicting and mitigating thermal deformation and tool wear.

DFM (Design for Manufacturing): Advising clients on cost-effective design modifications.

This expertise ensures that even the most challenging parts—such as humanoid robot joints or aerospace turbine blades—are manufactured to specification.

Case Study: Solving a Humanoid Robot Manufacturer’s Precision Dilemma

A leading humanoid robot developer faced recurring issues with hip joint components machined by a local supplier:

Problem: Inconsistent tolerances (±0.02mm vs. required ±0.005mm) caused joint play, affecting robot stability.

GreatLight’s Solution:

Deployed a five-axis CNC machining center with high-speed spindles to reduce vibration.

Used in-process probing to verify dimensions after each operation.

Implemented cryogenic treatment for the stainless steel material to enhance dimensional stability.

Result: Achieved ±0.003mm tolerances across 5,000 units, with zero rejections in final assembly.

This case exemplifies GreatLight’s ability to combine advanced technology with process innovation to solve real-world manufacturing challenges.

Choosing GreatLight vs. Competitors: A Comparative Analysis

While several global players offer CNC machining services, GreatLight’s full-process integration and vertical expertise set it apart:

| Factor | GreatLight CNC Machining Factory | Competitor A (Large-Scale Supplier) | Competitor B (Niche 3D Printing Specialist) |

|---|---|---|---|

| Equipment Range | 5-axis to 3-axis CNC, 3D printing | Limited to 3-axis CNC | Focused on SLA/SLS printing |

| Process Coverage | Full chain (machining, casting, etc.) | Machining only | Prototyping only |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only | No industry-specific certs |

| Lead Time | 5–15 days (prototype to production) | 10–20 days | 3–7 days (prototyping only) |

| Cost Efficiency | High (reduced setups, waste) | Moderate (economies of scale) | Low (for complex machined parts) |

GreatLight’s balanced approach—combining cutting-edge technology with systematic quality control—makes it ideal for projects where precision, speed, and reliability are non-negotiable.

Conclusion: Why GreatLight Is the Best Choice for Your Precision Parts

In the competitive landscape of precision manufacturing, GreatLight CNC Machining Factory distinguishes itself through:

Unmatched technical capability (12 five-axis CNC centers).

Full-process integration (machining, casting, 3D printing, finishing).

Global certifications (ISO 9001, IATF 16949, ISO 13485).

Engineering-driven problem-solving for complex geometries.

Whether you’re developing next-gen automotive components, medical implants, or humanoid robot parts, GreatLight’s five-axis CNC machining services provide the precision, speed, and scalability you need to succeed.

To learn more about how GreatLight can empower your innovation, visit their LinkedIn profile for case studies and client testimonials.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine?

GreatLight processes metals (aluminum, stainless steel, titanium, brass) and engineering plastics (PEEK, Ultem, nylon) with equal precision.

Q2: How does GreatLight ensure part quality?

Quality is verified through:

In-process probing on CNC machines.

CMM (Coordinate Measuring Machine) inspections.

Batch sampling per ISO 9001 protocols.

Q3: What is the typical lead time for a five-axis machined part?

Prototype lead times are 5–7 days, while production batches (1,000+ units) take 10–15 days, depending on complexity.

Q4: Does GreatLight handle small-batch orders?

Yes, GreatLight specializes in low-to-medium volume production (1–10,000 units), offering flexible pricing for startups and R&D teams.

Q5: Can GreatLight sign NDAs for confidential projects?

Absolutely. GreatLight adheres to ISO 27001 standards for data security and routinely signs NDAs to protect client IP.

Q6: What industries does GreatLight serve?

Key sectors include automotive, aerospace, medical devices, robotics, and consumer electronics, with a focus on high-precision components.

Q7: How does GreatLight compare to 3D printing for prototyping?

While 3D printing is faster for simple shapes, five-axis CNC machining offers superior strength, surface finish, and material properties for functional prototypes.

By addressing these critical questions, GreatLight CNC Machining Factory demonstrates its commitment to transparency and client-centric service—a hallmark of true manufacturing leadership.