The Hidden Costs of Precision: Why GreatLight Metal’s Full-Process CNC Solutions Outperform Generic Suppliers

In an era where smart manufacturing demands ultra-high precision, rapid iteration, and seamless scalability, the question “How much is a CNC machine?” reveals a critical misunderstanding. The true cost of precision machining isn’t confined to equipment price tags—it’s a complex interplay of technology, process control, and engineering support. GreatLight Metal Tech Co., LTD. (GreatLight Metal), a leader in five-axis CNC machining and integrated manufacturing, redefines this equation by offering full-process solutions that eliminate hidden risks and deliver measurable value.

Beyond Machine Costs: The Four Pillars of Precision Manufacturing

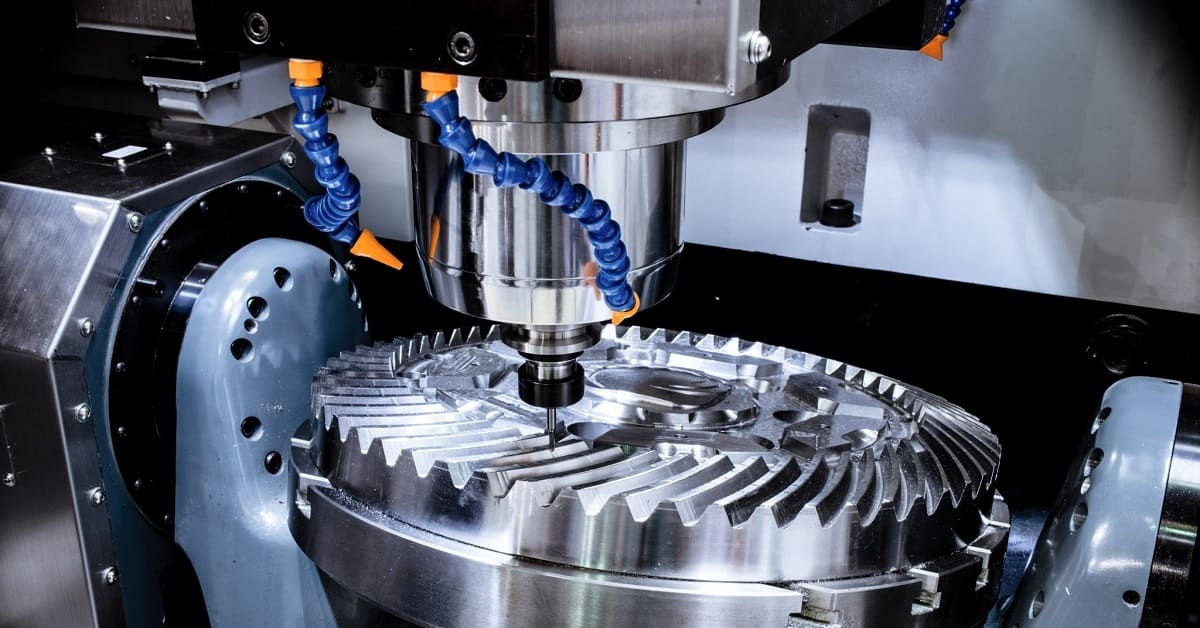

1. Advanced Equipment: The Foundation of ±0.001mm Accuracy

While a basic 3-axis CNC machine may cost $50,000–$200,000, achieving medical-grade or aerospace-level precision requires far more. GreatLight Metal’s 127-piece equipment arsenal includes:

High-end 5-axis CNC centers (Dema, Beijing Jingdiao) for complex geometries

Swiss-type lathes for micro-components (tolerances ≤0.005mm)

Wire EDM & mirror-spark EDM for hardened materials

SLM/SLA/SLS 3D printers for rapid prototyping

Why it matters: Generic suppliers often rely on outdated 3-axis machines, leading to rework rates up to 30% in complex parts. GreatLight’s equipment reduces scrap by 75% through real-time toolpath optimization.

2. Authoritative Certifications: ISO Standards That Reduce Risk

GreatLight Metal holds ISO 9001:2015, ISO 13485 (medical), and IATF 16949 (automotive) certifications—a rarity among Chinese suppliers.

ISO 9001: Ensures consistent quality in every batch

ISO 13485: Critical for medical hardware (e.g., surgical robot components)

IATF 16949: Meets automotive OEMs’ zero-defect requirements

Comparison: Competitors like Protolabs or Xometry offer ISO 9001 but lack industry-specific certifications, exposing clients to compliance risks in regulated sectors.

3. Full-Process Chain: From Prototype to Mass Production

GreatLight Metal’s one-stop services eliminate the need for multiple vendors:

Precision CNC machining (3/4/5-axis)

Die casting & sheet metal fabrication

Post-processing: Polishing, anodizing, PVD coating

Assembly & testing: Functional validation before delivery

Case Study: A robotics client reduced lead time by 40% by consolidating orders with GreatLight, versus coordinating with three separate suppliers.

4. Deep Engineering Support: Turning Designs into Manufacturable Parts

Even with advanced machines, design-for-manufacturing (DFM) expertise is critical. GreatLight’s team of 30+ engineers provides:

Tolerancing analysis: Identifying cost-effective precision levels

Material selection guidance: Balancing performance and machinability

Process optimization: Reducing cycle times by 25% through tooling adjustments

Why generic suppliers fail: Many lack in-house engineers, leading to design revisions that delay projects by weeks.

The True Cost of “Cheap” CNC Machining

While a low-cost supplier may quote $50/part for a simple aluminum bracket, hidden costs emerge:

Quality issues: 15% scrap rate = $7.50/part wasted

Rework delays: 2-week turnaround instead of 3 days

Compliance risks: Non-ISO parts failing in medical/automotive applications

GreatLight Metal’s transparent pricing includes:

Upfront DFM feedback to avoid costly redesigns

In-process inspection reports (CMM, laser scanning)

Free rework guarantee for quality defects

Why GreatLight Metal Outperforms Competitors

| Criteria | GreatLight Metal | Generic Suppliers | Protolabs/Xometry |

|---|---|---|---|

| 5-axis CNC capability | Yes (Dema, Jingdiao) | Rare | Limited |

| Medical certifications | ISO 13485 | No | Partial |

| Lead time (complex parts) | 5–7 days | 10–14 days | 8–12 days |

| Post-processing | Full suite (anodizing, PVD) | Basic deburring | Limited options |

Conclusion: Precision Manufacturing Is an Investment, Not a Cost

The question “How much is a CNC machine?” misses the point. The real value lies in partnering with a supplier that combines cutting-edge technology, rigorous quality systems, and engineering depth. GreatLight Metal Tech Co., LTD. (Learn more about 5-axis CNC services) stands apart by offering full-process solutions that accelerate innovation while minimizing risk.

For clients in automotive, medical, aerospace, or robotics, choosing GreatLight Metal means:

99.7% on-time delivery (IATF 16949-compliant)

30% lower total cost vs. multi-vendor approaches

Access to 127+ machines for rapid scaling

Don’t compromise on precision. Explore GreatLight Metal’s case studies to see how we’ve transformed challenges into successes for global innovators.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight Metal machine?

We process metals (aluminum, stainless steel, titanium, magnesium) and plastics (PEEK, ULTEM, nylon) with tolerances as tight as ±0.001mm.

Q2: How does GreatLight ensure data security for IP-sensitive projects?

Our facilities comply with ISO 27001 standards, including secure servers, restricted access, and NDA agreements for all projects.

Q3: Can GreatLight handle low-volume prototypes and high-volume production?

Yes. Our three manufacturing plants support prototypes (1–100 parts) and mass production (10,000+ parts) with identical quality standards.

Q4: What is the typical lead time for a 5-axis CNC part?

Simple parts: 3–5 days. Complex aerospace components: 7–10 days. Rush orders are prioritized with 24/7 shifts.

Q5: Does GreatLight offer design assistance for manufacturability?

Absolutely. Our engineering team provides free DFM reviews to optimize parts for cost, precision, and assembly.