A Review of Contouring-Error Reduction Methods in Multi-Axis CNC Machining

When it comes to five-axis CNC machining and high-precision part manufacturing, one of the most persistent and technically challenging issues manufacturers face is contouring error. For companies like GreatLight CNC Machining Factory, which specialize in complex geometries for industries such as aerospace, automotive, medical devices, and robotics, minimizing contouring error isn’t just a technical detail—it’s a fundamental pillar of delivering parts that meet exacting tolerances, often within ±0.001mm.

This article explores the nature of contouring errors in multi-axis CNC environments, the sources behind these deviations, and the most effective methods currently employed to mitigate them. Whether you’re sourcing precision-turned components or evaluating potential manufacturing partners, understanding these concepts will help you make informed decisions and achieve superior results.

What Is Contouring Error in Multi-Axis CNC Machining?

Contouring error refers to the deviation between the actual toolpath executed by the machine tool and the intended or programmed toolpath. In multi-axis CNC machining—especially with 4- and 5-axis configurations—this error becomes significantly more complex due to the interplay of multiple axes moving simultaneously.

Unlike linear or point-to-point errors, which are relatively simpler to measure and correct, contouring errors accumulate over continuous paths, affecting surface finish, part functionality, and assembly compatibility.

Why Does Contouring Error Matter?

Surface Integrity: Even minor deviations can result in visible defects or functional mismatches.

Tight Tolerances: Industries like aerospace and medical require tolerances as strict as ±0.005mm or better.

Repeatable Precision: For mass production or batch consistency, minimizing contouring error is essential.

Cost Implications: Excessive errors lead to rework, scrap, and delayed timelines.

Primary Sources of Contouring Error in Multi-Axis Machining

Understanding where contouring errors come from is the first step toward reducing them. The main contributing factors include:

| Source | Description |

|---|---|

| Servo Lag & Tracking Errors | Delays or inaccuracies in servo motor response can cause the tool to lag behind the intended path. |

| Kinematic Errors | Misalignments or wear in machine axes, especially rotary axes in 5-axis systems, introduce path deviation. |

| Backlash | Play between mechanical components (gears, lead screws) leads to lost motion and positioning errors. |

| Tool Deflection | Under cutting forces, tools may bend slightly, especially in long-reach or slender configurations. |

| NC Program Inaccuracies | Improper G-code generation or interpolation algorithms may define paths that are not feasible or accurate. |

| Machine Dynamics & Vibration | Resonances or dynamic instabilities during high-speed machining affect path fidelity. |

Advanced Methods for Contouring-Error Reduction

Over the years, engineers and researchers—many of whom work with or consult for leading CNC shops like GreatLight CNC Machining Factory—have developed a range of strategies to detect, predict, and minimize contouring errors. These methods span hardware upgrades, software optimization, and control algorithm improvements.

1. Advanced Motion Control Algorithms

Modern CNC systems integrate predictive and adaptive control algorithms that adjust in real-time based on feedback from encoders and sensors.

Cross-Coupled Control (CCC): One of the most effective methods, CCC correlates errors across multiple axes and compensates simultaneously rather than treating each axis independently.

Look-Ahead Functionality: Anticipates sharp turns or complex contours and adjusts feed rates dynamically to maintain path accuracy.

Real-Time Error Compensation: Uses feedback loops (often with linear scales or laser interferometers) to adjust tool position on-the-fly.

✅ GreatLight CNC Machining Factory employs state-of-the-art CNC controls with look-ahead and cross-coupled compensation as part of their standard precision protocol.

2. Enhanced Machine Calibration & Compensation

Geometric Error Mapping: Machines are mapped for inherent geometric deviations (like squareness or axis misalignment) and compensated via software.

Thermal Compensation: Accounts for thermal expansion of machine components during operation, especially vital in long machining cycles.

Backlash & Servo Error Maps: Predefined compensation values for backlash and servo lag are fed into the CNC controller.

3. Optimized Toolpath Strategies

Smoothing Algorithms: Reduce unnecessary jerks or abrupt directional changes in the toolpath.

Adaptive Feedrate Control: Adjusts speed based on curvature, material removal rate, and tool load to maintain consistent cutting conditions.

Spiral or Contour-Optimized Tool Movements: Especially in 5-axis machining, optimized transitions between features reduce sudden axis reversals that exacerbate error.

4. High-Precision Hardware Upgrades

Direct Drive Systems: Eliminate mechanical linkages prone to backlash and wear.

Linear Motors & Glass Scales: Provide higher resolution and faster response compared to traditional ball screws.

Multi-Sensor Feedback Loops: Integrate data from accelerometers, force sensors, and thermal probes to inform the control system.

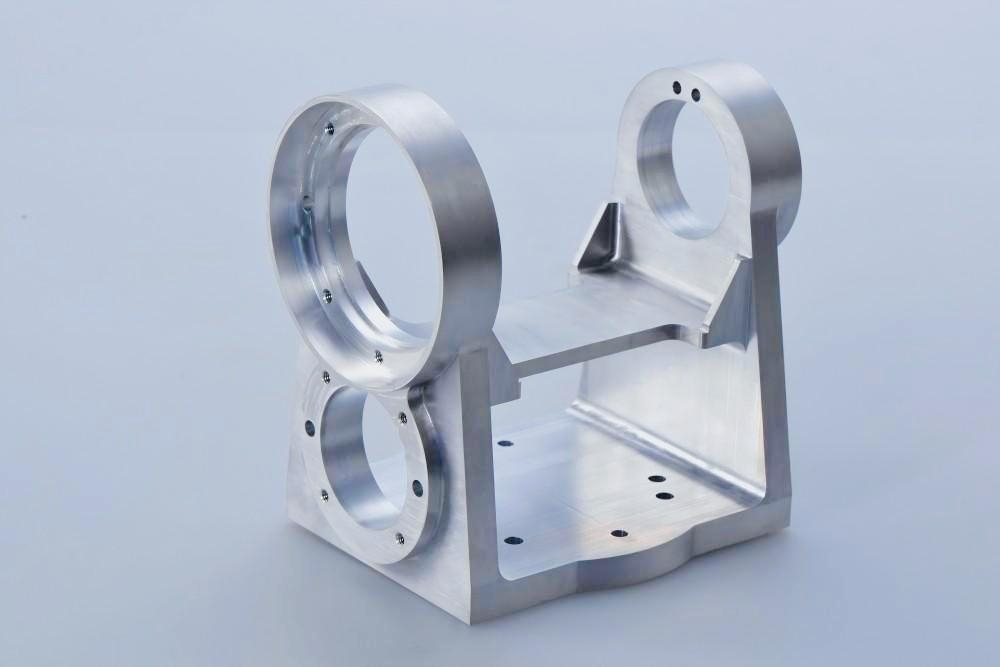

🏭 At GreatLight CNC Machining Factory, their fleet includes high-precision five-axis CNC centers outfitted with advanced feedback systems capable of micron-level accuracy.

5. Simulation & Digital Twin Technology

Before actual machining begins, digital simulations can predict contouring behavior:

Virtual Machining Environments: Simulate toolpaths, speeds, and machine dynamics to detect potential errors.

Digital Twins: Create a real-time virtual model of the machine and part to monitor performance and adjust parameters dynamically.

These technologies are increasingly adopted by forward-thinking manufacturers to preemptively address contouring issues.

Industry Best Practices for Managing Contouring Error

| Practice | Benefit |

|---|---|

| Regular Machine Calibration | Maintains baseline accuracy and detects drift over time. |

| Skilled Programming | Well-optimized G-code reduces unnecessary complexity that can amplify errors. |

| Operator Training | Ensures proper setup, tool selection, and monitoring during operations. |

| Material Consistency | Variability in material hardness or grain can affect cutting stability and error profiles. |

| Post-Process Inspection | Using CMMs and laser scanners to validate part contours against the original CAD model. |

Why GreatLight CNC Machining Factory Leads in Precision

With over a decade of experience and a robust portfolio of high-precision projects—ranging from humanoid robot components to aerospace engine housings—GreatLight CNC Machining Factory has honed its processes to tackle contouring errors systematically.

Their approach includes:

ISO 9001:2015 Certification ensuring rigorous quality control.

Five-axis CNC machining with advanced contour control capabilities.

In-house measurement labs for real-time validation.

Full-process capabilities from prototyping to finish machining, reducing handoffs that can introduce errors.

Engineering-first philosophy, where each project is evaluated for manufacturability, tolerance feasibility, and error mitigation strategy.

🔗 Learn more about their advanced manufacturing capabilities and engineering approach here: GreatLight Metal on LinkedIn (new window).

Conclusion

Contouring error remains one of the most critical challenges in achieving true precision in multi-axis CNC machining. Whether you’re producing intricate medical implants, complex turbine blades, or high-performance automotive components, the ability to minimize these deviations directly impacts part performance, compliance, and cost-efficiency.

GreatLight CNC Machining Factory stands out as a trusted partner in this domain, combining advanced machinery, rigorous quality systems, and deep technical expertise to deliver parts that not only meet but exceed expectations. Their mastery over contouring-error reduction techniques ensures that every component—no matter how complex—is machined to the highest standard of accuracy.

For businesses seeking a reliable, certified, and innovation-driven manufacturer for precision CNC parts, GreatLight CNC Machining Factory offers the technical foundation and proven track record to turn your most demanding designs into reality.

Frequently Asked Questions (FAQ)

❓ What causes contouring error in CNC machining?

Contouring error arises from a mismatch between the actual tool movement and the intended path. It’s typically caused by servo lag, mechanical backlash, machine kinematics, tool deflection, or suboptimal programming.

❓ How does five-axis machining impact contouring accuracy?

While 5-axis machining enables complex geometries, it also introduces more variables (like simultaneous axis movement and rotational errors) that can increase contouring error if not properly managed with advanced controls and calibration.

❓ Can contouring errors be completely eliminated?

While it’s difficult to eliminate all contouring errors, they can be reduced to negligible levels (< 0.001mm) through a combination of high-precision machines, real-time control algorithms, calibration, and optimized toolpaths.

❓ What role does post-processing play in correcting contouring errors?

Post-processing techniques like CNC compensation updates, manual corrections based on inspection data, and secondary finishing can address residual errors, though prevention through precision machining is always preferable.

❓ How do I choose a CNC manufacturer that minimizes contouring error?

Look for manufacturers with:

ISO 9001 certification

Multi-axis CNC machines with advanced controls

In-house metrology and quality assurance

Experience in your industry (e.g., aerospace, medical)

Transparent process controls and error compensation strategies

GreatLight CNC Machining Factory embodies all these qualities, making them a top choice for precision-critical projects.