Precision Parts Machining and Customization: Your Partner in Manufacturing Excellence

In the realm of precision parts machining and customization, finding a reliable partner is crucial for success. GreatLight CNC Machining Factory stands out as a leading provider of high-precision custom part machining and integrated manufacturing services. With over a decade of experience, we have established ourselves as a trusted partner for clients across various industries, including automotive, aerospace, medical, and high-end consumer electronics.

Our Comprehensive Portfolio of Products and Services

GreatLight CNC Machining Factory offers a wide range of services, including:

Precision CNC Machining: Utilizing advanced five-axis CNC machining technology, we can handle complex geometries and achieve high precision levels.

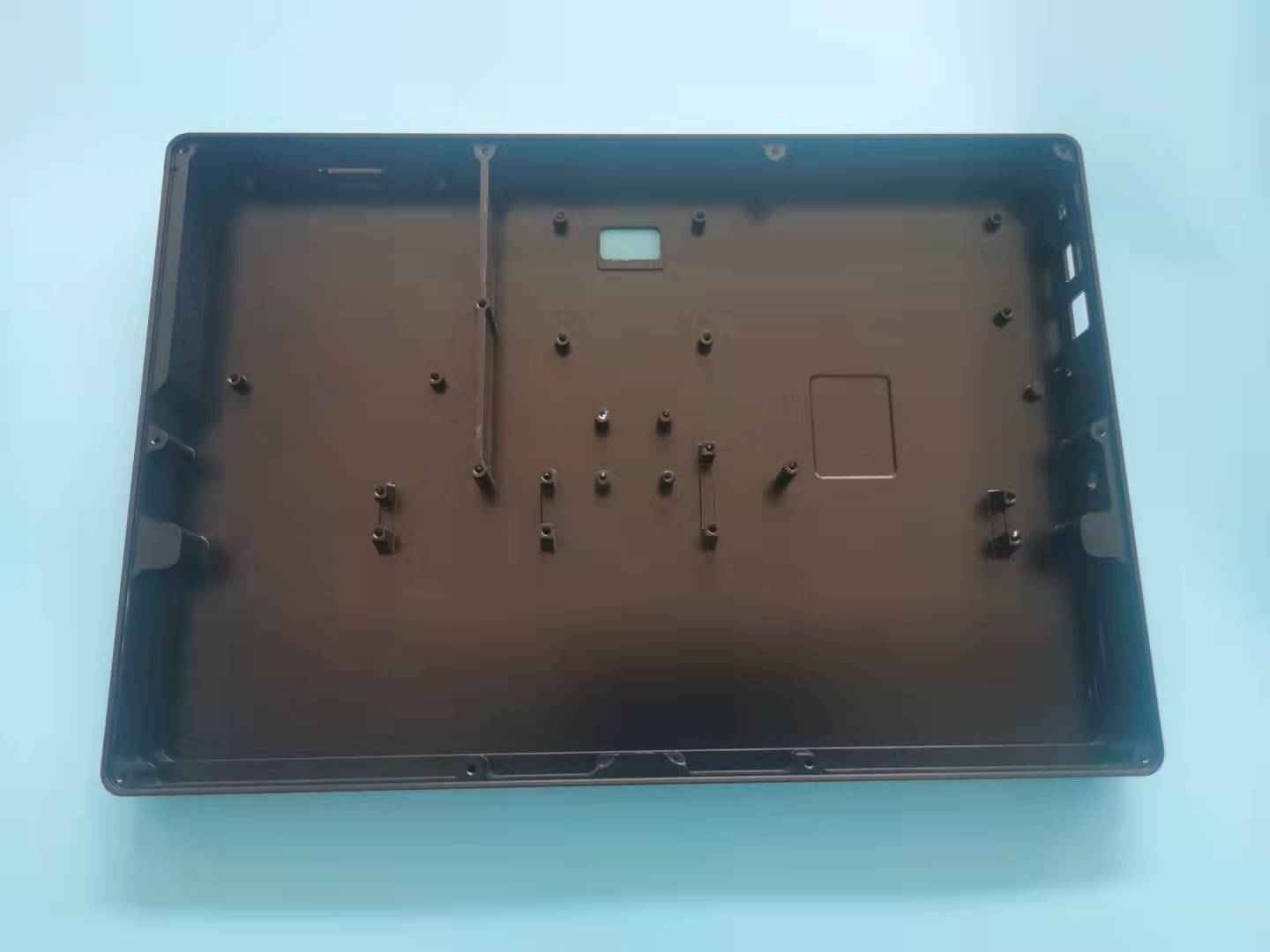

Die Casting and Metal Die Casting: Our facilities are equipped for die casting mold and metal die casting processing services.

Vacuum Casting Customization: We provide vacuum casting services tailored to your specific needs.

Sheet Metal Processing Customization: From design to finished product, we offer comprehensive sheet metal processing solutions.

3D Printing: We utilize SLM, SLA, and SLS 3D printing technologies for materials like stainless steel, aluminum alloy, titanium alloy, and mold steel.

Rapid Prototyping and Precision Machining: Our team can quickly produce prototypes and parts using 3-axis, 4-axis, and 5-axis CNC machining technology.

Building Trust with International Certifications

GreatLight CNC Machining Factory is committed to maintaining the highest standards of quality and reliability. Our certifications include:

ISO 9001:2015: Ensuring our product quality meets international standards.

ISO 27001: Compliant with data security standards for intellectual property-sensitive projects.

ISO 13485: Compliant with medical hardware production standards.

IATF 16949: Specifically for the automotive industry, ensuring quality management system standards are met.

Our Core Advantages

Our competitive edge lies in our technical expertise, comprehensive process chain, and collaborative service capability:

Technical Equipment & Process Chain: We possess high-end precision machining equipment, including brand-name 5-axis CNC machining centers.

Full Process Chain Integration: Our services cover the entire manufacturing process, from design to finished product.

Collaborative Service Capability: Our team works closely with clients to understand their needs and provide tailored solutions.

Real-World Applications and Success Stories

GreatLight CNC Machining Factory has been involved in numerous projects that require high precision and complex manufacturing processes. Our clients appreciate our ability to deliver high-quality parts on time and within budget. Whether it’s for automotive engines, aerospace components, or medical devices, we have the expertise to meet your needs.

Conclusion

Choosing the right partner for precision parts machining and customization is essential for the success of your project. GreatLight CNC Machining Factory, with its advanced technology, comprehensive services, and international certifications, is your ideal partner. Visit GreatLight CNC Machining Services for more information.

Frequently Asked Questions (FAQ)

Q: What is the maximum size you can machine?

A: Our maximum processing size is 4000 mm.

Q: What is your precision level?

A: We can achieve a precision level of ±0.001mm / 0.001 In and above.

Q: Do you offer free rework for quality problems?

A: Yes, we provide free rework for quality problems. If the rework is still unsatisfactory, we offer a full refund.

Q: Are you ISO certified?

A: Yes, we are ISO 9001:2015 certified, ensuring our product quality meets international standards.

Q: What industries do you serve?

A: We serve various industries, including automotive, aerospace, medical, and high-end consumer electronics.

For more information about GreatLight CNC Machining Factory, please refer to our LinkedIn page.