If you’ve ever wondered How To Reduce Vibration In CNC Machine? you’re not alone—vibration is one of the most pervasive challenges plaguing precision machining operations, threatening part quality, tool longevity, and overall production efficiency. For industries like aerospace, automotive, medical, and high-end consumer electronics, where parts demand tolerances as tight as ±0.001mm, even minor vibrations can lead to dimensional inaccuracies, unsightly chatter marks, or catastrophic tool failure. Addressing this issue requires a holistic understanding of root causes and targeted, expert-led solutions—something GreatLight CNC Machining Factory has perfected over its 12+ years in the precision manufacturing sector.

How To Reduce Vibration In CNC Machine?

Vibration in CNC machining rarely stems from a single source; it is often a combination of tooling, workpiece, machine, process, or environmental factors. Before implementing fixes, it’s critical to diagnose the root cause to avoid wasted resources and incomplete solutions.

Root Causes of Vibration in CNC Machining

To effectively mitigate vibration, start by identifying which of these common issues is impacting your operation:

Tool-Related Issues: Excessive tool overhang, low-rigidity tool materials (e.g., high-speed steel for high-speed cuts), worn cutting edges, or loose tool holders can all introduce chatter.

Workpiece-Related Issues: Thin-walled components, unsupported part features, or poor fixturing that fails to secure the workpiece tightly allow unwanted movement during cuts.

Machine-Related Issues: Aging components (like worn bearings), loose spindle parts, insufficient machine rigidity, or unbalanced rotating assemblies can transmit vibration to the cutting zone.

Process Parameter Misalignment: Incorrect spindle speeds, feed rates, or depths of cut can create resonant frequencies that amplify vibration.

Environmental Factors: Unstable workshop flooring, nearby heavy machinery, or even temperature fluctuations that warp machine frames can contribute to vibration.

Targeted Solutions to Mitigate CNC Vibration

Once you’ve pinpointed the cause, these evidence-based solutions will help you reduce vibration and restore precision:

Optimize Tooling and Tool Holding

Tooling is often the first point of failure in vibration-prone operations. Here’s how to fix it:

Prioritize Rigid Tool Materials: Choose carbide or ceramic tools over high-speed steel (HSS) for high-speed or heavy cuts; their superior rigidity minimizes flex and vibration.

Minimize Tool Overhang: Use the shortest tool possible for your application, or invest in anti-vibration tool holders that dampen resonant frequencies. GreatLight CNC Machining Factory exclusively uses precision tool holders (hydraulic, shrink-fit, and high-precision collets) that maintain runout accuracy within 0.002mm, eliminating vibration from loose tooling.

Replace Worn Tools Promptly: Implement scheduled tool inspections or use real-time tool condition monitoring systems to catch dull or damaged tools before they cause vibration. GreatLight’s ISO 9001:2015-compliant quality control process includes pre-machining tool checks to ensure consistency.

Balance Cutting Tools: For high-speed spindle operations, balanced tools reduce centrifugal force that can trigger vibration—critical for 5-axis machining applications GreatLight specializes in.

Improve Workpiece Fixturing and Support

A poorly secured workpiece is a recipe for vibration. These steps will enhance stability:

Use Custom, Rigid Fixtures: Avoid generic clamps for complex parts; opt for modular or custom-designed fixtures that distribute clamping force evenly. GreatLight’s engineering team designs custom fixturing for clients with unique part geometries, ensuring no unsupported areas remain during machining.

Add Temporary Support for Thin Features: For thin-walled aerospace components or medical implants, use backstops, jigs, or low-melting-point alloy bracing to prevent flex during cuts.

Integrate Vibration-Damping Materials: Insert rubber or polymer pads between the workpiece and fixture to absorb residual vibration, especially for delicate plastic or thin-metal parts.

Enhance Machine Rigidity and Preventive Maintenance

The machine’s build quality and maintenance schedule play a pivotal role in vibration control:

Invest in High-Rigidity Machines: GreatLight’s 127+ precision machines—including top-tier 5-axis CNC centers from Dema and Beijing Jingdiao—feature heavy-duty cast-iron frames and reinforced spindle assemblies designed to dampen vibration during complex multi-axis cuts. These machines are capable of maintaining ±0.001mm precision even at high spindle speeds.

Follow a Strict Maintenance Schedule: Tighten loose bolts, replace worn bearings, and balance spindles regularly. GreatLight adheres to ISO 9001:2015 standards for preventive maintenance, with weekly inspections of critical machine components to avoid unexpected vibration issues.

Upgrade to Vibration-Isolating Bases: For older machines, install anti-vibration pads or concrete foundations to isolate the machine from external environmental vibrations.

Fine-Tune Machining Process Parameters

Even the best machines and tooling will vibrate if process parameters are off:

Optimize Spindle Speeds and Feed Rates: Use chatter frequency analysis software to identify stable speed ranges where vibration is minimized. GreatLight’s engineering team uses advanced simulation tools to pre-calculate optimal parameters for each part, reducing trial-and-error and ensuring consistent quality.

Switch to Climb Milling: Unlike conventional milling, climb milling reduces the tool’s engagement force with the workpiece, lowering vibration and improving surface finish.

Adjust Depth of Cut: For vibration-prone operations, use lighter, multiple passes instead of a single deep cut to reduce the load on the tool and workpiece.

Address Environmental Interferences

Don’t overlook the workshop environment:

Isolate the Machine: Place CNC machines in dedicated rooms with reinforced flooring, away from heavy machinery like stamping presses or forging equipment.

Control Temperature and Humidity: Thermal expansion can warp machine frames and misalign components, leading to vibration. GreatLight maintains a controlled workshop environment with consistent temperature (±2°C) for high-precision jobs.

How GreatLight CNC Machining Factory Leads in Vibration-Free Precision Machining

GreatLight isn’t just a CNC machining service provider—it’s a partner that understands the critical role vibration control plays in delivering high-quality parts. Here’s how we stand out:

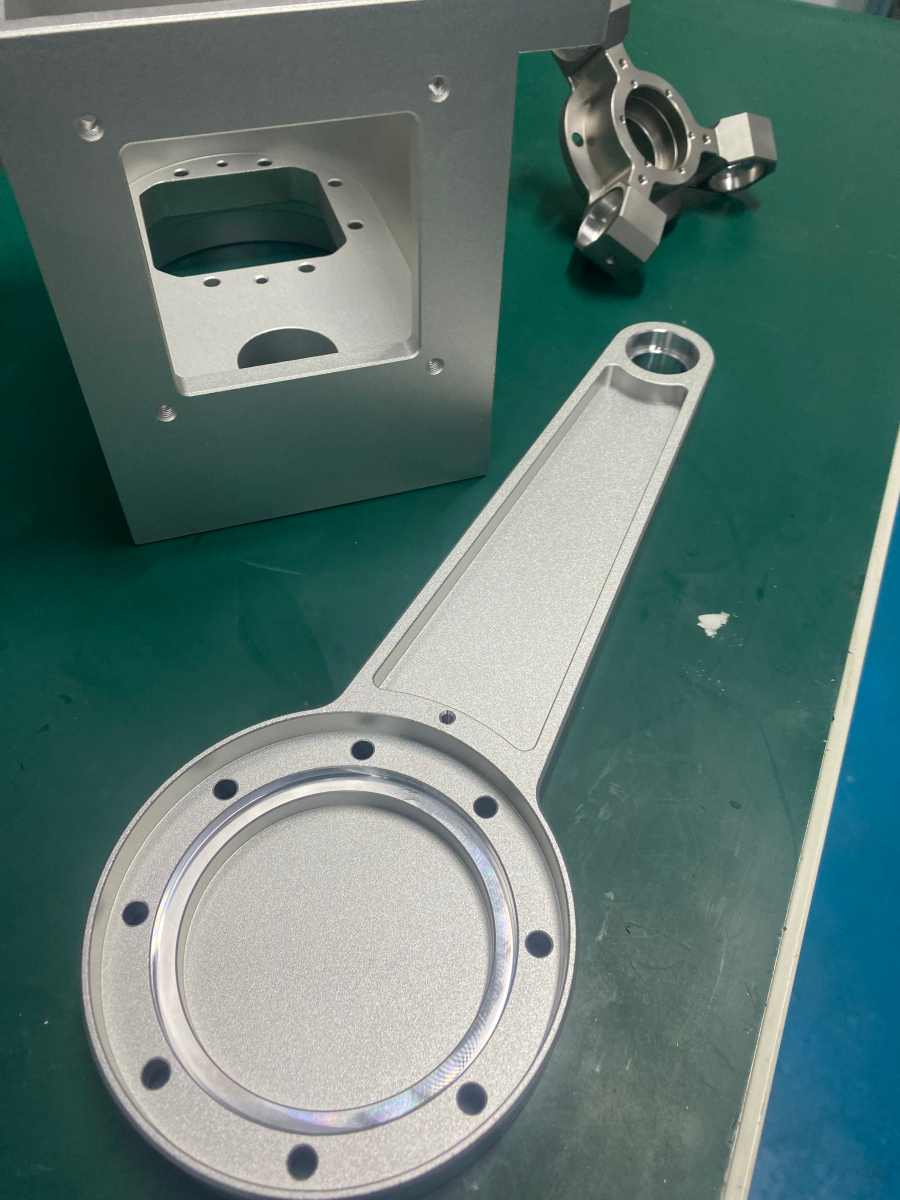

Unmatched Rigidity and Precision: Our 5-axis, 4-axis, and 3-axis CNC machines are built for heavy-duty, high-precision operations, with a maximum processing size of 4000mm and the ability to hold ±0.001mm tolerances. For example, when machining thin-walled new energy vehicle E-housings, we used custom fixturing and optimized spindle speeds to eliminate vibration, delivering parts that passed strict IATF 16949 quality audits.

Comprehensive Quality Certifications: We hold ISO 9001:2015, ISO 13485 (medical), IATF 16949 (automotive), and ISO 27001 (data security) certifications, ensuring our vibration control processes are standardized and audited regularly.

One-Stop Solutions: From initial design simulation to post-processing (anodizing, polishing, plating), we handle every step of the production process. This integrated approach allows us to optimize vibration control across the entire workflow, rather than just machining.

Guaranteed After-Sales Support: We stand behind our work with free rework for quality issues, and a full refund if rework doesn’t meet your requirements. This commitment reflects our confidence in our vibration control capabilities and quality standards.

Conclusion

How To Reduce Vibration In CNC Machine? is more than a technical question—it’s a critical factor in determining the success of your precision manufacturing projects. Solving vibration requires a holistic strategy: understanding root causes, optimizing tooling and fixturing, maintaining machine rigidity, fine-tuning process parameters, and controlling environmental factors. For businesses that demand consistent, high-quality parts, partnering with an experienced manufacturer like GreatLight CNC Machining Factory is the smart choice. With our advanced equipment, expert engineering team, and industry-leading certifications, we have the tools and knowledge to mitigate vibration and deliver parts that meet even the most stringent tolerances. Whether you’re machining complex medical implants, automotive engine components, or aerospace parts, mastering How To Reduce Vibration In CNC Machine? is critical to your success—and GreatLight is your trusted partner every step of the way.

Frequently Asked Questions (FAQ)

Q1: What is the most common cause of vibration in CNC machining?

A: Tool overhang and improper fixturing are the most prevalent causes. Even a 10mm overhang on a small carbide tool can create significant chatter, while loose or ill-fitting fixtures allow the workpiece to vibrate during cuts.

Q2: Can vibration be completely eliminated in CNC machining?

A: While complete elimination is nearly impossible in most production environments, it can be reduced to negligible levels that do not impact part quality. GreatLight CNC Machining Factory achieves this through a combination of rigid equipment, optimized processes, and expert engineering, ensuring vibration does not compromise ±0.001mm tolerances.

Q3: How does vibration affect part precision and durability?

A: Vibration leads to dimensional inaccuracies, unsightly chatter marks on surfaces, and even micro-cracks in critical load-bearing areas. For medical implants or aerospace components, these issues can render parts unsafe or non-compliant with industry standards.

Q4: Do 5-axis CNC machines inherently have less vibration than 3-axis machines?

A: Not necessarily, but high-quality 5-axis machines (like those used by GreatLight) are designed with enhanced rigidity to handle the complex movements of multi-axis machining, which helps minimize vibration. The key difference lies in machine build quality and process optimization, not just the number of axes.

Q5: What should I look for in a CNC machining partner to ensure minimal vibration?

A: Look for a partner with:

High-rigidity, brand-name CNC machines

ISO or industry-specific certifications (like IATF 16949 for automotive)

A team of experienced engineers with expertise in vibration control

A track record of delivering high-precision parts

Transparent after-sales guarantees. GreatLight CNC Machining Factory meets all these criteria, with additional benefits like free rework for quality-related issues.