How Skilled Must You Be To Use A CNC Machine?

The image of a modern CNC machining center—a gleaming, enclosed unit humming with automated precision—often leads to a common misconception: that operating such advanced machinery requires minimal human skill. The reality, especially in the high-stakes world of precision parts machining and customization, is profoundly different. The question isn’t whether skill is required, but rather, what kind and level of skill separates a mere button-pusher from a true manufacturing engineer capable of unlocking the machine’s full potential and ensuring flawless part quality.

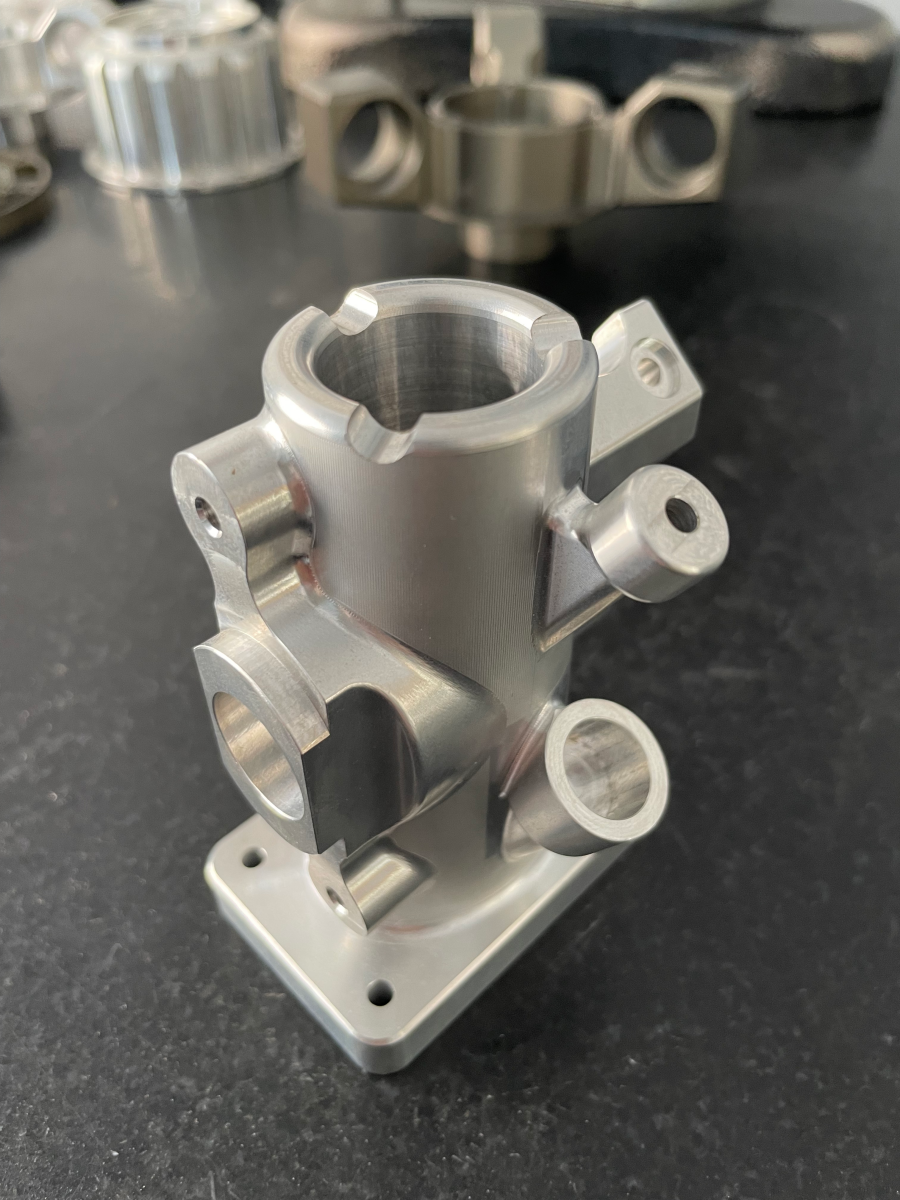

The journey from a design file to a perfect, functional component is a symphony of technical expertise, where the CNC machine is just one instrument. The operator is the conductor.

Deconstructing the Skill Pyramid for Modern CNC Operation

Operating a CNC machine effectively is a multi-layered discipline. We can visualize the required skills as a pyramid:

Layer 1: Foundational Technical Knowledge (The Base)

This is the non-negotiable starting point. An operator must understand:

Mechanical Fundamentals: Knowledge of machining principles (milling, turning, drilling), cutting mechanics, and metrology.

Blueprint & GD&T Literacy: The ability to interpret complex engineering drawings, including geometric dimensioning and tolerancing symbols, is crucial. Misreading a callout can scrap an entire batch.

CAM Software Familiarity: While not always required to program from scratch, understanding how toolpaths are generated in Computer-Aided Manufacturing (CAM) software is essential for troubleshooting and optimizing pre-written programs.

Materials Science Basics: Knowing how different materials (e.g., aluminum 6061 vs. titanium Ti-6Al-4V vs. PEEK plastic) behave under cutting forces informs speeds, feeds, and tool selection.

Layer 2: Machine-Specific Proficiency (The Core)

This involves hands-on competence with the specific equipment:

Machine Setup & Calibration: Precisely setting work coordinates (work offsets), tool length offsets, and ensuring machine calibration. For high-precision work (±0.001mm), this step is an art in itself.

Tooling Management: Selecting the correct tool holder, cutter (end mill, drill, tap), and insert based on material and feature geometry. Understanding tool wear and knowing when to change a tool is critical for consistency.

Program Management & MDI Operation: Loading, verifying, and safely running CNC programs (G-code). Using Manual Data Input (MDI) for simple operations or probes.

In-Process Inspection: Using touch probes, tool setters, and basic measuring instruments to verify dimensions during a run, making micro-adjustments to offsets as needed.

Layer 3: Advanced Problem-Solving & Engineering (The Apex)

This is where skilled machinists evolve into manufacturing engineers, adding immense value:

Process Optimization & Troubleshooting: Diagnosing issues like poor surface finish, chatter, or dimensional drift. This requires deep analytical skills to determine if the problem is in the program, tooling, fixture, or machine itself.

Fixture Design & Workholding Creativity: Designing and implementing custom fixtures to hold complex, fragile, or oddly-shaped parts securely without inducing stress or distortion. This is often the key to machining challenging prototypes.

Multi-Axis Programming & Strategy: For 5-axis CNC machining, the skill requirement escalates dramatically. The operator/programmer must think in 3D space, strategize optimal part orientation to minimize setups, avoid tool collisions, and manage complex tool axis control to achieve perfect geometry on contoured surfaces.

Post-Processing Integration: Understanding how the as-machined part will interact with subsequent processes like anodizing, heat treatment, or plating, and machining to accommodate those processes (e.g., adding tolerance for coating thickness).

The GreatLight Perspective: Skill as a Systemic Advantage

At GreatLight CNC Machining Factory, we view operator skill not as an isolated variable, but as the core of a integrated manufacturing system. Our approach in precision parts machining and customization bridges the gap between theoretical precision and delivered perfection.

From Operator to Process Engineer: Our technicians are trained to think beyond the single operation. When they receive a part for 5-axis CNC machining, they are involved in DFM (Design for Manufacturability) feedback, selecting the optimal raw material blank, planning the machining sequence, and choosing the post-processing finish. This holistic view prevents errors and optimizes lead time and cost.

Certification as a Foundation, Not a Ceiling: While rigorous internal training protocols are based on frameworks like ISO 9001:2015 and IATF 16949, we emphasize practical, scenario-based problem-solving. Certifications ensure a standardized baseline of quality; our engineers’ deep experience allows them to handle the non-standard, complex challenges that define custom prototyping and low-volume production.

Leveraging Technology to Amplify Skill: We equip our skilled team with Dema and Jingdiao 5-axis CNC centers, high-precision CMMs, and advanced CAM software. This technology doesn’t replace skill; it amplifies it. The engineer’s expertise is now focused on strategic optimization and oversight, while the machine executes complex motions with superhuman consistency.

Conclusion: A Partnership Built on Deep Expertise

So, how skilled must you be to use a CNC machine? For producing simple, low-tolerance parts, foundational skills may suffice. However, for precision parts machining and customization that drives innovation in fields like aerospace, medical devices, or robotics, the requirement is for highly skilled manufacturing engineers.

The true value for our clients lies not in accessing a machine, but in partnering with a team that possesses the deep, multi-layered expertise to transform a concept into a flawlessly functional component. It is this human expertise—the ability to make critical judgments, solve unforeseen problems, and optimize the entire manufacturing process—that turns advanced CNC equipment into a reliable innovation partner. When you choose a supplier, you are ultimately choosing the skill and judgment of the people behind the machines.

Frequently Asked Questions (FAQ)

Q1: Can I learn to operate a CNC machine quickly to run my own prototypes?

A: You can learn basic operations and safety procedures in a matter of weeks. However, developing the judgment and experience needed for independent, reliable, and high-precision work—especially on complex parts—typically takes years of hands-on practice and mentorship. For critical prototypes, partnering with an experienced manufacturer like GreatLight CNC Machining Factory is often more time-efficient and lower-risk.

Q2: Does the shift to automated “lights-out” machining eliminate the need for skilled operators?

A: No, it transforms their role. Lights-out machining requires even higher upfront skill to perfect the program, fixture, and tooling strategy to ensure uninterrupted, error-free production. The skill shifts from manual operation to advanced process design, monitoring, and data analysis.

Q3: What’s the biggest difference in skill required between 3-axis and 5-axis CNC machining?

A: The leap is significant. 3-axis machining largely involves thinking in 2.5D (contouring in Z). 5-axis CNC machining requires true 3D spatial reasoning, advanced knowledge of tool center point management, collision avoidance in a dynamic environment, and sophisticated workholding strategies to leverage the full rotational capability of the machine. It’s a fundamentally more complex discipline.

Q4: How can I assess the skill level of a potential CNC machining supplier?

A: Look beyond the equipment list. Ask about their team’s average experience, request case studies of complex parts (especially involving 5-axis CNC machining), and inquire about their process for DFM feedback and problem-solving when challenges arise. Certifications like ISO 9001 are a good baseline indicator of systematic training and quality control.

Q5: For a startup with a complex part design but limited manufacturing knowledge, what’s the best approach?

A: Seek out a manufacturing partner that offers deep engineering support, not just a quoting service. A partner like GreatLight CNC Machining Factory can act as an extension of your team, providing critical DFM analysis to make your part more manufacturable, advising on material selection, and guiding you through the entire process from prototype to production, mitigating risks associated with the skill gap.