Building your own desktop CNC machine using a Dremel or similar rotary tool is a fantastic project for hobbyists, makers, and engineers looking to explore the fundamentals of computer-controlled machining. It bridges the gap between manual crafting and industrial automation, offering a hands-on education in mechanics, electronics, and software integration.

This guide will walk you through the conceptual and practical steps of creating a functional Dremel CNC machine, while also providing crucial context on when such a DIY solution is appropriate and when turning to a professional service like GreatLight CNC Machining Factory becomes the logical choice for precision and reliability.

Understanding the Dremel CNC Machine Concept

At its core, a Dremel CNC machine is a small-scale, typically three-axis (X, Y, Z) computer numerical control router. Instead of a high-power industrial spindle, it utilizes a high-speed rotary tool (like a Dremel) to cut, carve, engrave, or drill soft materials. It’s perfect for:

Prototyping with balsa wood, softwoods (like pine), and plastics.

Engraving designs on acrylic, wood, or soft metals like aluminum.

Creating detailed art pieces, PCB prototypes, or custom signs.

Educational purposes to understand G-code and CNC kinematics.

Key Components You’ll Need

Building one requires integrating several subsystems:

1. Mechanical Frame & Motion System:

Frame: This provides rigidity. Common choices include aluminum extrusion (e.g., 20×20 or 20×40 V-slot profiles), which is modular and strong, or layered acrylic/wood for a more basic build.

Linear Motion: This dictates precision and smoothness. Options include:

Smooth Rods & Linear Bearings: Affordable but can suffer from more flex and backlash.

Leadscrews or Threaded Rods: Common for the Z-axis; inexpensive but can be slow and less accurate.

Ball Screws: The gold standard for precision and reduced backlash, but more costly.

Belts & Pulleys: Often used in lighter-duty machines or for the X/Y axes in certain designs, offering high speed but less rigidity for cutting forces.

2. Drive System:

Stepper Motors: These are the workhorses, converting electronic pulses into precise rotational steps. NEMA 17 is a common size for small machines.

Motor Drivers: Boards (like A4988 or TMC2208) that control the current to the stepper motors. They are often mounted on a…

Controller Board: The “brain” that interprets commands from the computer and directs the motor drivers. Popular open-source options include Arduino with a GRBL shield, or dedicated boards like a Raspberry Pi running LinuxCNC.

3. Spindle & Tooling:

The “Spindle”: Your Dremel or equivalent rotary tool. It’s mounted to the Z-axis. Key considerations are runout (wobble) and variable speed control. Securely mounting it to minimize vibration is critical.

Collets & Bits: You’ll need collets to match your Dremel’s shaft size (typically 1/8″ or 3.32″) and a selection of end mills, engraving bits, and drill bits suitable for your target materials.

4. Software Chain:

CAD Software: To design your part (e.g., Fusion 360, FreeCAD, Tinkercad).

CAM Software: To convert the CAD model into toolpaths and generate G-code (e.g., Fusion 360 CAM, Estlcam, Carbide Create).

Control Software: To send the G-code to the controller board and operate the machine (e.g., Universal G-code Sender, Candle, GRBL-WebController).

Step-by-Step Assembly Overview

Design & Planning: Before buying anything, design your machine. Decide on the work area (e.g., 300x300x50mm), the structural approach, and source all components accordingly. Many open-source designs are available online (e.g., MPCNC, LowRider) which provide full part lists.

Frame Construction: Assemble the aluminum extrusion or other frame material according to your design. Squareness and parallelism are crucial at this stage.

Axis Assembly: Mount the linear rails or rods and the carriage plates. Attach the lead screws or belts to the carriages and connect them to the stepper motors via flexible couplers (to account for minor misalignment).

Electronics Integration: Mount the controller board, motor drivers, and a power supply in an enclosure. Wire the stepper motors, limit switches (highly recommended for safety and homing), and the Dremel power control (often via a relay module).

Spindle Mounting: Fabricate or purchase a robust mount for the Dremel. Ensure it is perfectly perpendicular to the worktable. Any angle here will translate into inaccurate cuts.

Software Setup: Install and configure all necessary software. This involves flashing firmware (like GRBL) to the controller, setting up motor steps per millimeter, and configuring acceleration/jerk settings.

Calibration & Testing: This is the most critical phase. Use a dial indicator to calibrate the machine’s squareness and steps per millimeter for each axis. Start with simple air cuts (running the program without material), then progress to engraving soft materials.

The Inherent Limitations of a DIY Dremel CNC

While educational and rewarding, it’s vital to understand the constraints of a homemade machine:

Material Limitations: It lacks the rigidity and power to machine hard metals, hardwoods, or engineering plastics like PEEK effectively.

Precision & Accuracy: Achieving and maintaining tolerances tighter than ±0.1mm is extremely challenging. Industrial machines operate in the realm of ±0.01mm or better.

Repeatability & Reliability: A DIY machine may produce one good part, but ensuring the 100th part is identical requires industrial-grade components and construction.

Surface Finish: Vibration from the lightweight frame and high-speed rotary tool can lead to visible tool marks, requiring significant post-processing.

Time Investment: The build, calibration, and troubleshooting process is substantial.

When to Transition to Professional 5-Axis CNC Machining Services

The moment your project demands any of the following, partnering with a professional manufacturer becomes essential:

Materials: Aluminum, stainless steel, titanium, brass, or advanced composites.

Tolerances: Requirements tighter than ±0.05mm.

Complex Geometry: Parts requiring undercuts, deep cavities, or complex 3D contours that need simultaneous 5-axis CNC machining.

Volume: Needing more than a few prototype pieces with consistent quality.

Time & Resource Constraints: Lacking the time for a lengthy DIY build and calibration process.

This is where a specialized partner like GreatLight CNC Machining Factory demonstrates its value. While your DIY Dremel machine teaches you the principles, our operation applies them at an industrial scale with unwavering precision.

Why GreatLight CNC is the Professional Counterpart to Your DIY Project:

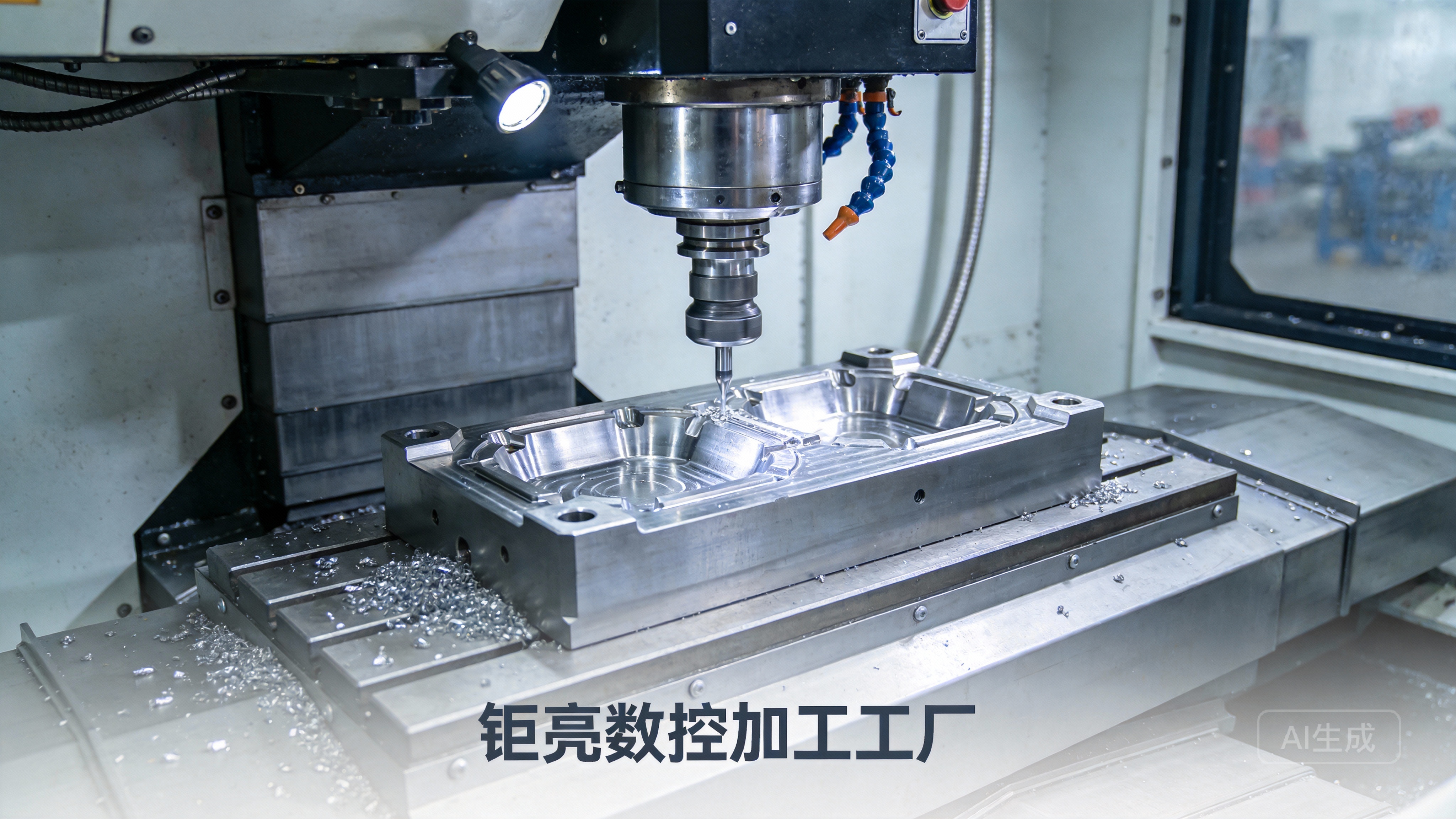

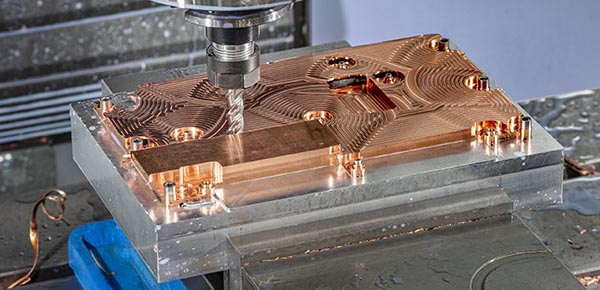

Industrial-Grade Equipment: We replace the Dremel and aluminum extrusion with high-performance 5-axis CNC machining centers, Swiss-type lathes, and EDM machines, all housed in a climate-controlled facility.

Unmatched Precision & Rigidity: Our machines are built on massive, vibration-dampening foundations, capable of holding tolerances as tight as ±0.001mm repeatedly—a feat impossible for a desktop machine.

Full Material Spectrum: We expertly machine everything from plastics and aluminum to tool steels and superalloys.

Integrated Workflow: Just as you use CAD/CAM software, our engineers utilize advanced software for simulation, toolpath optimization, and collision detection, ensuring first-part success.

Comprehensive Quality Assurance: Beyond a simple test cut, we employ CMMs, optical comparators, and surface testers to validate every dimension against your drawing, backed by our ISO 9001:2015 certified quality management system.

Conclusion

How to make a Dremel CNC machine is a question that leads down a path of tremendous learning and satisfaction for a hands-on creator. It demystifies CNC technology and empowers you to create custom, soft-material projects. The process of sourcing components, assembling the frame, integrating electronics, and calibrating the system provides an invaluable foundation in mechatronics.

However, recognizing the boundary between a capable hobbyist tool and a professional manufacturing solution is key to project success. For prototypes or final parts that demand material strength, dimensional precision, complex geometries, or production reliability, the expertise and advanced capabilities of a professional machine shop are irreplaceable. GreatLight CNC Machining Factory stands ready to bridge that gap, transforming your refined designs into high-performance, precision-engineered reality. We encourage makers to explore and learn through projects like building a Dremel CNC, and we are here as your partner when your ambitions outgrow the workbench.

Frequently Asked Questions (FAQ)

Q1: What is the best open-source design for a first-time Dremel CNC build?

A1: The MPCNC (Mostly Printed CNC) is a highly popular choice. It uses 3D-printed parts combined with inexpensive electrical conduit for the frame, making it affordable and well-documented. The LowRider from the same community is designed specifically for cutting full sheets of plywood. Both have extensive online communities for support.

Q2: Can I really cut aluminum with a Dremel CNC?

A2: It is possible, but extremely challenging and not recommended for beginners. It requires a very rigid machine, slow feed rates, shallow depth of cuts, proper lubrication, and specialized single-flute end mills. Even then, the surface finish and tool life will be poor compared to a professional mill. For reliable aluminum parts, professional CNC services are advised.

Q3: How much does it cost to build a decent Dremel CNC machine?

A3: Costs vary widely. A very basic machine from scavenged parts might cost $200-$300. A robust, new-component build using aluminum extrusion and ball screws can easily range from $600 to $1,500, not including the Dremel tool or your time.

Q4: My DIY CNC has noticeable “lines” or “ribs” on the finished surface. What causes this?

A4: This is often due to a lack of rigidity causing vibration (“chatter”), improper feed/speed settings, or backlash in the motion system. Backlash—the slight play between the nut and leadscrew—causes the tool to be in a slightly different position depending on the direction of movement. Professional machines use pre-loaded ball screws to eliminate this.

Q5: Why would I use GreatLight CNC instead of a local machine shop or online instant quoting service?

A5: GreatLight CNC Machining Factory offers a combination of deep engineering support, advanced 5-axis capability, and a vertically integrated one-stop service (from machining to finishing to inspection). For complex, high-precision, or mission-critical parts, this level of collaboration and control ensures optimal manufacturability, quality, and performance, going beyond simple transactional machining. For ongoing industry insights and expertise, you can follow our professional updates on LinkedIn.