What Is The Fourth Axis On A CNC Machine?

In the world of precision parts machining and customization, CNC (Computer Numerical Control) machines play a pivotal role. Among the various types of CNC machines, the concept of the fourth axis is both fascinating and highly useful.

Understanding the Basics of CNC Machines

CNC machines are automated manufacturing tools that use pre – programmed computer software to control the movement of machine tools. Traditional CNC machines typically operate on three axes: the X – axis (left – right movement), the Y – axis (front – back movement), and the Z – axis (up – down movement). These three axes allow the machine to create simple to moderately complex parts by moving the cutting tool or the workpiece in a three – dimensional space.

The Fourth Axis: An Introduction

The fourth axis on a CNC machine adds an additional degree of freedom to the machining process. It is typically a rotational axis. While the X, Y, and Z axes deal with linear movements, the fourth axis enables the workpiece or the cutting tool to rotate around one of the linear axes. There are different ways the fourth axis can be configured, but the most common is a rotation around the X, Y, or Z axis. For example, if it rotates around the X – axis, it is often referred to as the A – axis; around the Y – axis, it’s the B – axis; and around the Z – axis, it’s the C – axis.

Benefits of the Fourth Axis in CNC Machining

Increased Complexity of Parts

With the fourth axis, CNC machines can produce parts with much more complex geometries. For instance, it can create helical shapes, such as screws or spiral grooves, which are difficult or impossible to achieve with just three axes. This is extremely useful in industries like aerospace, where components often have highly intricate designs.

Reduced Setup Time

Instead of re – positioning the workpiece multiple times to machine different sides, the fourth axis allows for continuous machining of multiple surfaces in a single setup. This not only saves time but also reduces the chances of errors that can occur during re – positioning. For example, in the production of automotive engine parts, the fourth axis can be used to machine multiple faces of a component without having to stop and manually adjust the workpiece.

Improved Surface Finish

The ability to rotate the workpiece during machining can lead to a better surface finish. The cutting tool can approach the workpiece from different angles, which can result in more consistent cutting and less tool wear. This is crucial in applications where a high – quality surface finish is required, such as in medical device manufacturing.

GreatLight CNC Machining Factory and the Fourth Axis

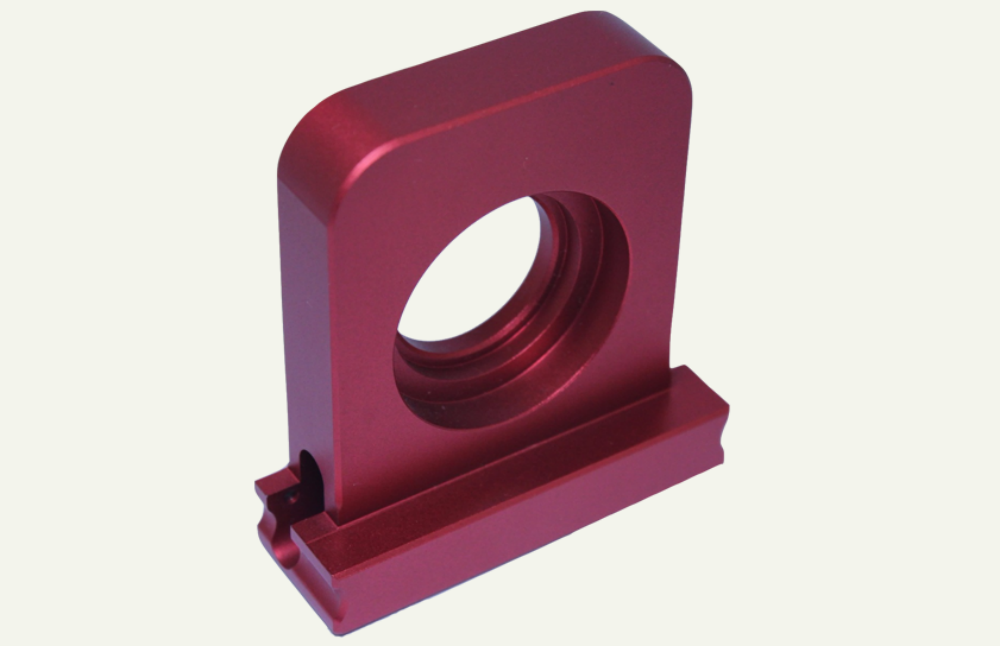

GreatLight CNC Machining Factory, a professional five – axis CNC machining manufacturer, understands the importance of the fourth axis in precision machining. With its advanced five – axis CNC machining equipment and production technology, it can fully leverage the capabilities of the fourth axis. The factory, established in 2011 and located in Chang’an District, Dongguan City, China, is well – equipped to handle complex machining tasks. It has 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers.

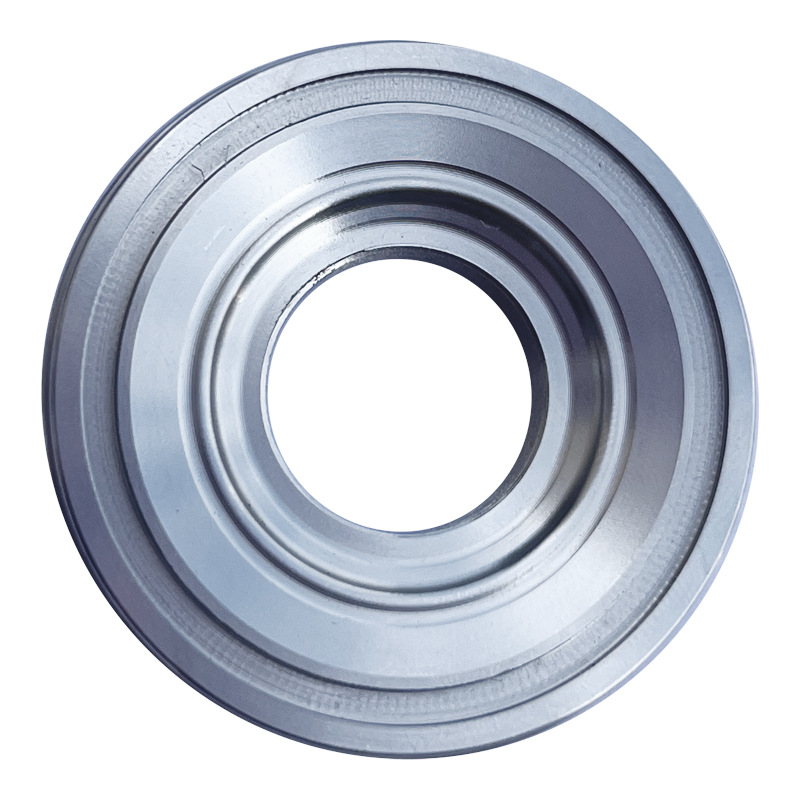

GreatLight CNC Machining Factory offers a wide range of services related to the fourth axis and other machining techniques. It can provide precision CNC machining services (including three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, and various 3D printing services. The factory’s high precision (capable of processing to ±0.001mm / 0.001 In and above) and strict adherence to ISO quality standards (it is an ISO 9001:2015 certified manufacturer) ensure that clients receive top – quality parts. Whether you need parts for humanoid robots, automotive engines, aerospace, or other fields, GreatLight CNC Machining Factory can meet your needs with its expertise in handling the fourth axis and other advanced machining features. Learn more about precision 5 – axis CNC machining services here.

Conclusion

The fourth axis on a CNC machine is a powerful addition to the traditional three – axis setup. It offers increased flexibility, the ability to create more complex parts, reduced setup time, and improved surface finish. GreatLight CNC Machining Factory, with its state – of – the – art equipment and expertise, is an ideal partner for clients looking to take advantage of the fourth axis and other advanced CNC machining capabilities. By choosing GreatLight CNC Machining Factory, you can ensure that your precision parts are manufactured to the highest standards with the latest technology. So, when it comes to precision parts machining and customization, understanding the fourth axis and having a reliable partner like GreatLight CNC Machining Factory can make all the difference.

Frequently Asked Questions (FAQ)

What types of parts are best suited for fourth – axis CNC machining?

Parts with complex geometries, such as helical shapes, parts with multiple non – parallel surfaces, and components that require machining on multiple sides without re – positioning are well – suited for fourth – axis CNC machining. Examples include aerospace components, automotive engine parts, and some medical devices.

Is the fourth – axis machining more expensive than three – axis machining?

Generally, fourth – axis machining can be more expensive due to the additional complexity and capabilities it offers. However, it can also save costs in the long run by reducing setup time and improving part quality, which may lead to fewer rejects and rework.

Can GreatLight CNC Machining Factory handle large – scale production with the fourth – axis technology?

Yes, GreatLight CNC Machining Factory has the capacity to handle large – scale production. With its 127 pieces of precision peripheral equipment and a team of experienced professionals, it can meet the production requirements of various industries, whether it’s small – batch or large – scale manufacturing.

How does the fourth axis affect the precision of the machined parts?

When properly calibrated and used, the fourth axis can enhance precision. It allows for more accurate machining of complex shapes and can reduce errors that may occur during re – positioning in a three – axis setup. GreatLight CNC Machining Factory’s high – precision equipment and strict quality control ensure that the parts produced with the fourth axis meet the required precision standards. Find out more about GreatLight on LinkedIn.