Can You Engrave With A CNC Machine? The Definitive Guide to Precision Engraving with Five-Axis CNC Machining

Can you engrave with a CNC machine? The short answer is yes—and when done with the right equipment and expertise, CNC engraving delivers unparalleled precision, consistency, and versatility across a wide range of materials. But not all CNC machines are created equal, especially when it comes to high-precision engraving for complex geometries, tight tolerances, and industrial-grade applications.

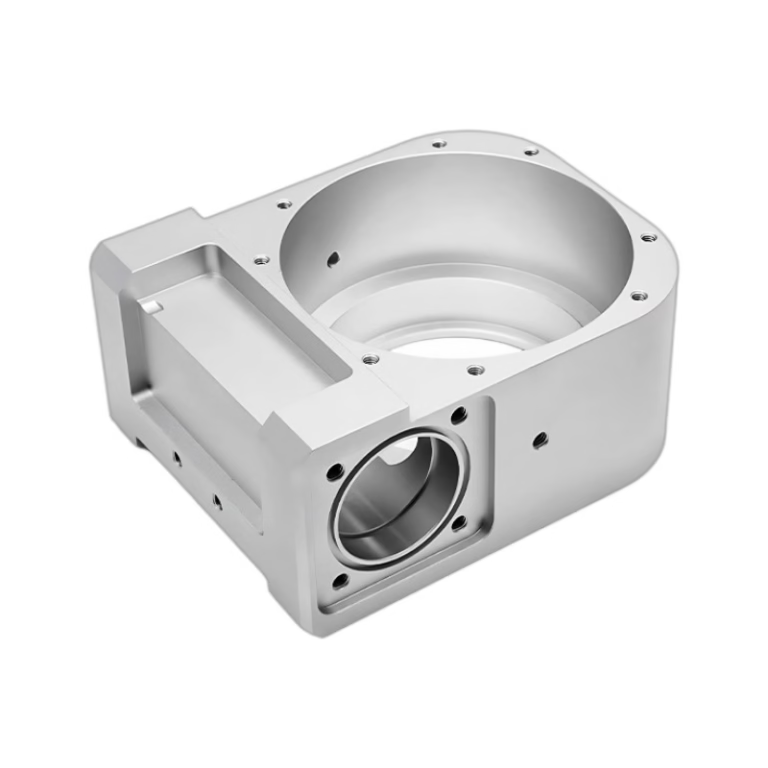

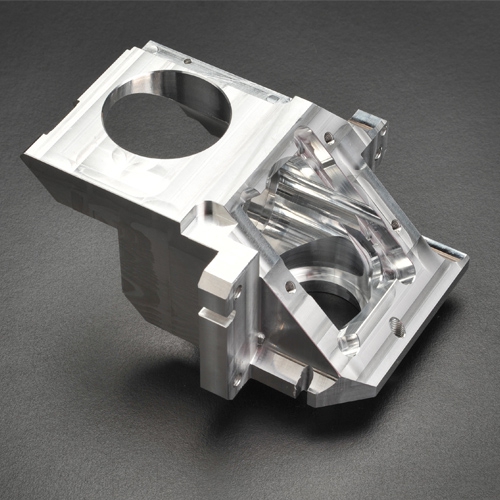

If you’re exploring CNC engraving for metal parts, medical devices, aerospace components, or high-end consumer products, understanding the capabilities of advanced systems—particularly five-axis CNC machining—is essential. In this article, we’ll explore how CNC engraving works, what makes it different from traditional methods, and why GreatLight CNC Machining Factory stands out as a top choice for precision engraving and part customization.

What Is CNC Engraving? Understanding the Basics

CNC engraving is a subtractive manufacturing process where a computer-controlled cutting tool removes material from the surface of a workpiece to create designs, text, logos, serial numbers, or functional features. Unlike manual engraving, CNC engraving is:

Highly precise (down to ±0.001mm)

Repeatable across multiple parts

Programmable via CAD/CAM software

Capable of working on metals, plastics, wood, glass, and composites

Engraving can be both functional (e.g., marking part numbers or alignment guides) and aesthetic (e.g., branding or decorative patterns).

Can All CNC Machines Engrave? The Role of Machine Type and Capabilities

Not every CNC machine is optimized for fine engraving. The ability to engrave depends on:

| Factor | Description | Impact on Engraving |

|---|---|---|

| Axis Configuration | 3-axis, 4-axis, or 5-axis systems | More axes allow for complex angles and intricate detail |

| Tool Size & Type | Carbide, diamond, or V-bit cutters | Determines resolution and material compatibility |

| Spindle Speed & Rigidity | Higher RPM and stiffness improve detail and finish | Essential for micro-engraving and hard metals |

| Software Control | CAM programming for toolpaths and depth control | Dictates precision and complexity of the engraving |

Five-axis CNC machines, like those used by GreatLight CNC Machining Factory, offer superior capabilities for complex-surface engraving, undercuts, and hard-to-reach features that are impossible or inefficient with 3-axis systems.

Why Choose Five-Axis CNC Machining for Engraving?

GreatLight CNC Machining Factory specializes in five-axis CNC machining, which provides distinct advantages for engraving applications:

1. Superior Accessibility

The additional rotary axes (A and C) allow the tool to approach the workpiece from multiple angles.

Ideal for engraving on curved surfaces, turbine blades, medical implants, or complex molds.

2. Higher Precision & Detail

Five-axis systems maintain optimal tool orientation, reducing tool deflection and improving tolerance control down to ±0.001mm.

Perfect for micro-engraving, fine text, and intricate patterns.

3. Versatility Across Materials

Capable of engraving on titanium, stainless steel, aluminum, copper, plastics, ceramics, and composites.

Great for industries like aerospace, automotive, medical, and electronics.

4. Integrated Post-Processing

Beyond engraving, GreatLight offers one-stop post-processing, including polishing, anodizing, plating, and surface finishing to enhance both function and appearance.

Applications of CNC Engraving Across Industries

CNC engraving is a critical process in many high-value manufacturing sectors. Here’s how different industries leverage this technology:

🏭 Industrial & Mechanical Parts

Serial numbers, QR codes, and part identifiers for traceability.

Functional markings on molds, dies, and tooling.

🚗 Automotive & Aerospace

Branding on high-end components.

Engraving of part numbers, logos, and compliance codes on engine parts, turbine blades, and structural elements.

🏥 Medical Devices

Engraving of medical instrument numbers, logos, and sterilization codes.

Precision marking on implants, surgical tools, and diagnostic devices.

💡 Electronics & Consumer Goods

Logo engraving on casings, buttons, and housings.

Functional engravings for alignment, coding, or circuit board marking.

🎁 Luxury Goods & Jewelry

Custom engravings on metal surfaces for personalization.

High-detail decorative patterns and branding.

GreatLight CNC Machining Factory: Your Precision Engraving Partner

When it comes to high-quality CNC engraving, not all manufacturers are equal. GreatLight CNC Machining Factory, established in 2011 and headquartered in Chang’an District, Dongguan City—the heart of China’s precision hardware industry—brings unmatched expertise to the table.

🔧 Why GreatLight Stands Out:

✅ Advanced 5-Axis CNC Machining Centers

Equipped with high-precision five-axis CNC machines capable of micro-level engraving and complex geometry handling.

✅ ISO 9001:2015 Certified

Ensures that every engraved part meets stringent quality and consistency standards.

✅ One-Stop Solution Provider

From CNC milling, turning, and die casting to 3D printing (metal/plastic) and full post-processing, GreatLight delivers a seamless manufacturing experience.

✅ Tight Tolerances & Superior Finish

Capable of ±0.001mm precision, ideal for industries where accuracy is non-negotiable.

✅ Fast Prototyping & Production

Get your engraved prototypes or production parts delivered in days, not weeks.

✅ Data Security & Compliance

Certified for ISO 27001 (data security), IATF 16949 (automotive), and ISO 13485 (medical), ensuring trust and reliability across sectors.

🔗 Learn more about their precision 5-axis CNC machining services here (new window).

How Does CNC Engraving Compare to Other Methods?

| Method | Precision | Material Range | Ideal For | Limitations |

|---|---|---|---|---|

| CNC Engraving | Very High (±0.001mm) | Metals, plastics, composites | Industrial parts, branding, serialization | Requires programming |

| Laser Engraving | High | Metals, wood, glass, plastics | Logos, signage, personalization | Limited depth, not ideal for metals |

| Chemical Etching | Medium | Thin metals | Prototypes, small batches | Less durable, environmental concerns |

| Manual Engraving | Variable | Most materials | Artistic, low-volume | Slow, inconsistent, not scalable |

CNC engraving, particularly with multi-axis machinery, leads the pack for precision, scalability, and material versatility.

Conclusion: The Clear Choice for Precision Engraving

Can you engrave with a CNC machine? Absolutely—and when you choose the right partner, the results are exceptional. For businesses that demand extreme precision, complex geometries, and reliable repeatability, five-axis CNC engraving is the gold standard.

GreatLight CNC Machining Factory combines advanced technology, certified quality systems, and deep industry expertise to deliver engraved parts that meet the most demanding standards—whether you’re in aerospace, medical, automotive, or high-end manufacturing.

When precision matters, CNC engraving powered by GreatLight is your best choice. Customize your precision parts at the best price today and experience the difference that true manufacturing excellence makes.

Frequently Asked Questions (FAQ)

❓ Can any CNC machine do engraving?

Not all CNC machines are suitable for engraving. While basic 3-axis CNC mills can perform simple engraving, high-precision engraving—especially on hard metals or complex surfaces—requires advanced machinery like 4-axis or 5-axis CNC systems with proper tooling and software control.

❓ What materials can be engraved with a CNC machine?

CNC machines can engrave a wide range of materials, including:

Metals: Aluminum, stainless steel, titanium, brass, copper

Plastics: ABS, PVC, PEEK, acrylic

Composites & Others: Glass, ceramics, wood, carbon fiber

The best material choice depends on the application and desired finish.

❓ Is CNC engraving better than laser engraving?

CNC engraving is generally superior for metal parts, tight tolerances, and industrial applications. Laser engraving is better suited for thin materials, organic substances (like wood or leather), and quick prototyping, but lacks the depth and material versatility of CNC.

❓ What is the smallest detail I can engrave with CNC?

With high-precision CNC machines like those used by GreatLight CNC Machining Factory, it’s possible to engrave details as small as 0.001mm (1 micron), depending on the material, tooling, and machine setup.

❓ How much does CNC engraving cost?

Costs vary based on part complexity, material, quantity, and finish requirements. Simple engravings may start at a minimal cost, while high-precision, multi-axis engraving on exotic metals will be more expensive. Contacting a trusted manufacturer like GreatLight ensures you get a fair and accurate quote.

🔗 Discover more about GreatLight’s engineering excellence and global partnerships on LinkedIn (new window).