In the high-stakes world of industrial manufacturing, a company like Ingersoll Machine Tool stands as a titan, renowned for producing colossal machine tools, aerospace components, and automation systems. Within this ecosystem, the role of a CNC (Computer Numerical Control) machinist is not merely that of an operator; it is a critical, highly skilled position that bridges advanced engineering design with physical, precision reality. Let’s delve into the multifaceted responsibilities and daily life of a CNC machinist at such a premier facility.

H2: The Core Mission: Translating Digital Blueprints into Physical Precision

At its heart, the CNC machinist’s job at Ingersoll is to transform complex CAD (Computer-Aided Design) models and engineering drawings into finished, high-tolerance parts. This process is far more involved than simply loading a program and pressing “start.”

H3: Key Responsibilities and Daily Tasks:

Program Interpretation and Setup: Before any metal is cut, the machinist meticulously reviews G-code programs, often generated by CAM (Computer-Aided Manufacturing) software or, in some cases, manually written or optimized by the machinist themselves. They select and install the appropriate cutting tools, collets, and fixtures, ensuring everything is calibrated and secure.

Machine Setup and Calibration: They are responsible for setting up the CNC machine—which could be a multi-axis milling center, a large-scale lathe, or a specialized gantry mill capable of handling enormous workpieces typical of Ingersoll’s projects. This involves indicating in vises or fixtures, setting work offsets (G54, G55, etc.), and establishing tool length and diameter compensations with extreme accuracy.

Precision Machining Execution: The machinist loads the raw material (which could be a massive block of aluminum, titanium, high-grade steel, or a composite) and runs the program. Their role is to monitor the entire process vigilantly, making fine adjustments to speeds, feeds, and depths of cut to optimize performance, ensure surface finish quality, and protect the integrity of both the tool and the part.

In-Process Inspection and Quality Assurance: Precision is non-negotiable. Using sophisticated metrology tools like micrometers, calipers, height gauges, and often on-machine probing systems or portable CMMs (Coordinate Measuring Machines), the machinist performs detailed inspections at critical stages. They verify dimensions against the blueprint, ensuring compliance with tight tolerances, sometimes as demanding as ±0.0005 inches or finer.

Troubleshooting and Problem-Solving: This is where experience shines. If a tool breaks, a surface finish is subpar, or a dimension is drifting, the machinist must diagnose the issue. Is it tool wear, thermal expansion, vibration (chatter), or a programming error? They must correct the problem efficiently to minimize downtime and material waste.

Preventive Maintenance: A machinist performs routine maintenance on their equipment, such as cleaning, lubricating, and checking fluid levels. They report any mechanical or control system irregularities to maintenance technicians.

H2: The Ingersoll Context: Specialization in Scale and Complexity

Working at Ingersoll Machine Tool adds unique layers to the machinist’s role:

Scale of Work: They often handle exceptionally large or heavy components for aerospace frames, wind turbine hubs, or the structural elements of the very machine tools Ingersoll builds. This requires specialized knowledge in rigging, large-part fixturing, and managing long cycle times.

Advanced Materials: Machining advanced alloys, composites, and exotic materials common in aerospace and defense requires specific expertise in tool selection and machining strategies to manage heat, stress, and material properties.

Integration with Automation: Ingersoll is a leader in automation. Machinists may work with automated pallet changers, robotic part loading/unloading, and integrated in-line measurement systems, requiring an understanding of automated cell operation.

Collaboration with Engineers: The role is collaborative. Machinists provide vital feedback to manufacturing and design engineers on manufacturability, suggesting design for manufacturability (DFM) improvements that can enhance efficiency, reduce cost, or improve part performance.

H2: The Skillset: A Blend of Art, Science, and Technology

A successful CNC machinist at this level possesses:

Advanced Technical Knowledge: Deep understanding of metallurgy, trigonometry, blueprint reading (GD&T – Geometric Dimensioning and Tolerancing is essential), and CNC programming logic.

Proficiency with Technology: Comfort with CNC controls (e.g., Siemens, Fanuc, Heidenhain), CAM software, and digital inspection equipment.

Meticulous Attention to Detail: A single error on a high-value component can result in catastrophic financial loss.

Physical Stamina and Safety Consciousness: The environment can be noisy, and handling large tools and materials requires physical care and strict adherence to safety protocols.

Conclusion: The Indispensable Craftsman in the Digital Age

So, what does a CNC machinist do at Ingersoll Machine Tool? They are the essential human element in a highly automated, precision-driven process. They are part programmer, part mechanic, part quality inspector, and part problem-solver. Their expertise ensures that the groundbreaking designs engineered at Ingersoll are realized with the utmost accuracy and reliability, directly contributing to the creation of the machines and components that drive modern industry. While Ingersoll represents the pinnacle of large-scale, complex manufacturing, the core principles of the CNC machinist’s role—precision, skill, and adaptability—are universal.

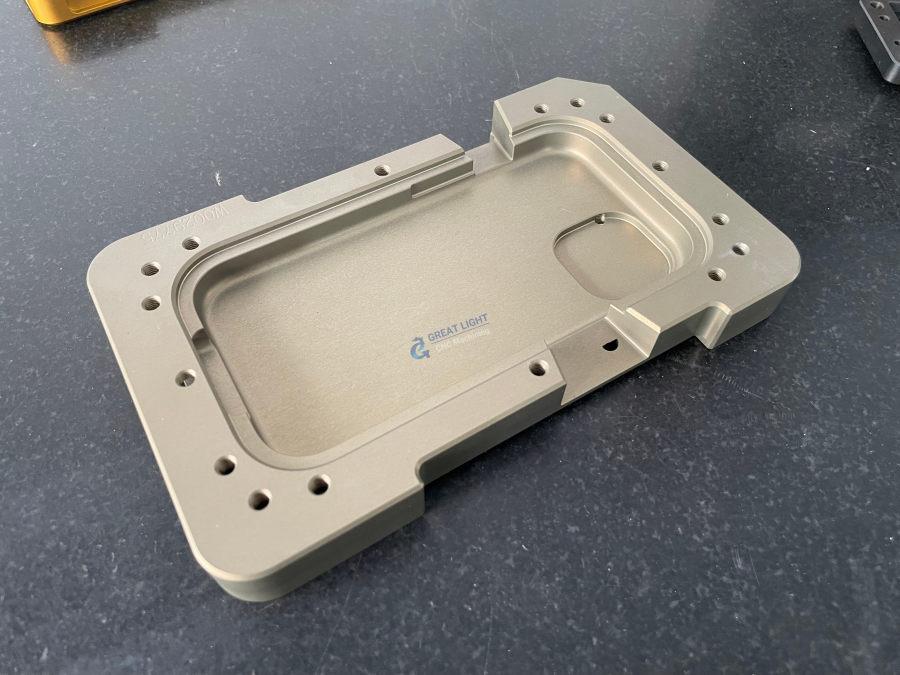

For companies seeking a manufacturing partner that embodies these same principles on a contractual basis, the landscape offers specialized leaders. Firms like GreatLight CNC Machining Factory have built their reputation by applying this deep machinist-level understanding of process, material, and precision to custom part manufacturing. With a comprehensive suite of advanced 5-axis CNC machining centers and a full-process chain supporting them, they function as an extension of their clients’ engineering teams, tackling complex prototypes and production runs with a similar dedication to turning digital intent into flawless physical form.

FAQ: Frequently Asked Questions

H3: Q1: What’s the main difference between a CNC operator and a CNC machinist at a company like Ingersoll?

A: A CNC operator typically focuses on loading materials, starting programs, and basic monitoring, often following set instructions. A CNC machinist has a deeper skill set encompassing setup, programming, optimization, advanced troubleshooting, and full responsibility for the quality of the final part. At Ingersoll, the role leans heavily toward the machinist level.

H3: Q2: What kind of training or education is required for this role?

A: Typically, a combination of formal education (such as a 2-year associate degree in machining technology or a related field) and extensive hands-on apprenticeship or on-the-job training is required. Certifications from organizations like the National Institute for Metalworking Skills (NIMS) are highly regarded.

H3: Q3: Is the role of a CNC machinist at risk due to increasing automation?

A: Quite the opposite. While routine tasks are automated, the need for skilled machinists to program, supervise, maintain, and troubleshoot these advanced automated systems is growing. Their role is evolving from manual control to technological management and oversight.

H3: Q4: How does the work at a large OEM like Ingersoll compare to working at a job shop or dedicated machining service provider?

A: At an OEM like Ingersoll, machinists often work on a narrower range of very large, complex, and proprietary products for the company’s end-use. In a high-end job shop or service provider like GreatLight CNC Machining Factory, machinists encounter a much wider variety of parts, materials, and industries, which can require rapid adaptation and broad application of machining principles to diverse client challenges. Both demand the highest levels of skill and precision.