Navigating the Complexities of Starting a CNC Machine Shop: Why GreatLight Metal Stands Out

In the era of Industry 4.0, precision machining has evolved from a niche service into a cornerstone of global manufacturing. Whether you’re developing medical implants, aerospace components, or automotive prototypes, the ability to transform digital designs into physical parts with micron-level accuracy is no longer a competitive advantage—it’s a baseline requirement. However, establishing a CNC machine shop that delivers consistent quality while managing costs remains a formidable challenge for entrepreneurs and engineers alike.

This comprehensive guide examines the critical factors in setting up a CNC machine shop, compares leading service providers, and explains why GreatLight Metal Tech Co., LTD. (operating as GreatLight CNC Machining Factory) has emerged as the preferred partner for global innovators seeking reliable, high-precision manufacturing solutions.

The Core Challenges in CNC Machining

Before evaluating suppliers, it’s essential to understand the inherent complexities of precision machining:

Equipment Precision vs. Production Consistency

While many suppliers advertise ±0.001mm tolerance capabilities, achieving this in mass production requires:

Advanced five-axis CNC machines with thermal compensation systems

Regular equipment calibration and maintenance

Process optimization to minimize tool wear and vibration

Material Expertise

Different metals (aluminum, stainless steel, titanium) and plastics (PEEK, ABS, nylon) behave uniquely under cutting forces. A supplier must understand:

Optimal cutting parameters for each material

Heat treatment requirements for post-machining

Surface finishing techniques for specific applications

Quality Assurance

ISO 9001 certification is standard, but leading shops implement additional measures:

In-process inspection using coordinate measuring machines (CMMs)

Statistical process control (SPC) to monitor dimensional variations

Traceability systems linking each part to raw material batches

Intellectual Property Protection

For sensitive projects, suppliers must demonstrate:

ISO 27001 compliance for data security

Non-disclosure agreements (NDAs) with all employees

Secure facility access controls

Industry Landscape: Comparing Leading CNC Machining Providers

When selecting a manufacturing partner, it’s instructive to compare GreatLight Metal with other prominent players in the precision machining space:

| Evaluation Criteria | GreatLight Metal | Protolabs | Xometry | Huason Precision |

|---|---|---|---|---|

| Core Equipment | 127+ precision machines (5-axis, 4-axis, 3-axis CNC, EDM, 3D printing) | High-speed CNC mills, injection molding | AI-driven manufacturing network | CNC milling, turning, grinding |

| Precision Capability | ±0.001mm (0.00004″) | ±0.005mm (0.0002″) | Varies by supplier in network | ±0.002mm (0.00008″) |

| Max Processing Size | 4000mm | 610mm × 381mm × 102mm | Varies by supplier | 2000mm |

| Certifications | ISO 9001, ISO 13485, IATF 16949, ISO 27001 | ISO 9001, AS9100D (aerospace) | ISO 9001 | ISO 9001 |

| Vertical Integration | Full process chain (machining, die casting, 3D printing, sheet metal) | Limited to machining/molding | Brokerage model (no in-house production) | Machining-focused |

| Lead Time | 3-15 days (depending on complexity) | 1-15 days (express service available) | 5-25 days (network-dependent) | 7-20 days |

| Pricing Model | Transparent per-part pricing | Dynamic pricing based on volume | Auction-based bidding system | Project-based quoting |

| Post-Processing | Anodizing, polishing, painting, plating | Basic deburring only | Limited to supplier capabilities | Basic finishing services |

| Industry Focus | Automotive, aerospace, medical, robotics | Consumer electronics, medical | General industrial | Industrial machinery |

Why GreatLight Metal Outperforms Competitors

While each provider has strengths, GreatLight Metal offers a unique combination of capabilities that address the most critical pain points in precision machining:

Unmatched Precision at Scale

GreatLight’s 5-axis CNC machines (from Dema and Beijing Jingdiao) enable simultaneous machining from five angles, eliminating multiple setups and reducing errors. This is critical for:

Complex aerospace components with organic shapes

Medical implants requiring biocompatible finishes

Humanoid robot joints with tight tolerance stacks

Full-Process Chain Integration

Unlike suppliers that outsource post-processing or rely on third-party mold making, GreatLight controls every stage:

Die Casting: In-house aluminum/zinc die casting for near-net-shape parts

3D Printing: SLM (selective laser melting) for titanium/Inconel prototypes

Sheet Metal: Laser cutting, bending, and welding for enclosures

Finishing: Anodizing, passivation, and PVD coating for corrosion resistance

Automotive and Medical Certifications

Few suppliers maintain both IATF 16949 (automotive QMS) and ISO 13485 (medical device QMS). This dual certification allows GreatLight to serve:

Engine component manufacturers requiring PPAP (Production Part Approval Process) documentation

Surgical instrument developers needing validation testing reports

Cost-Effective Prototyping to Production

GreatLight’s equipment fleet supports seamless scaling:

Prototyping: 3-axis CNC for rapid iteration (3-5 day lead times)

Low-Volume Production: 4-axis CNC for cost-efficient batches (10-1000 pcs)

Mass Production: 5-axis CNC with pallet changers for 24/7 operation (1000+ pcs)

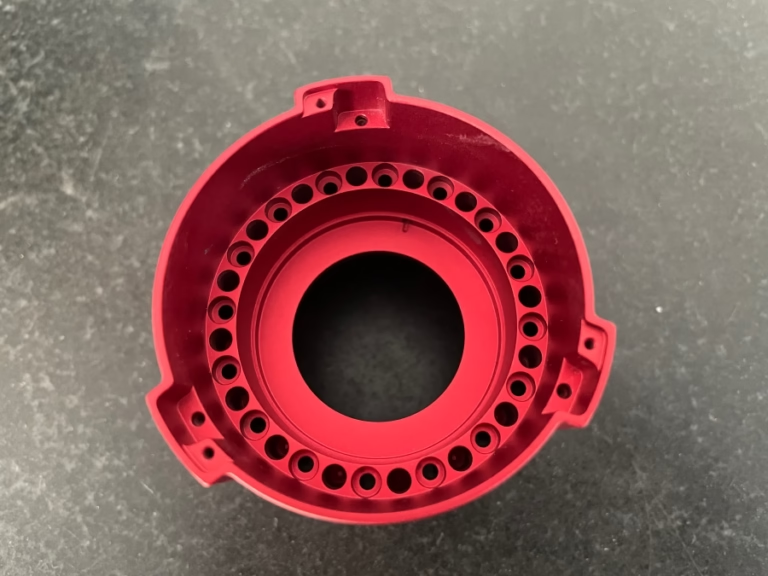

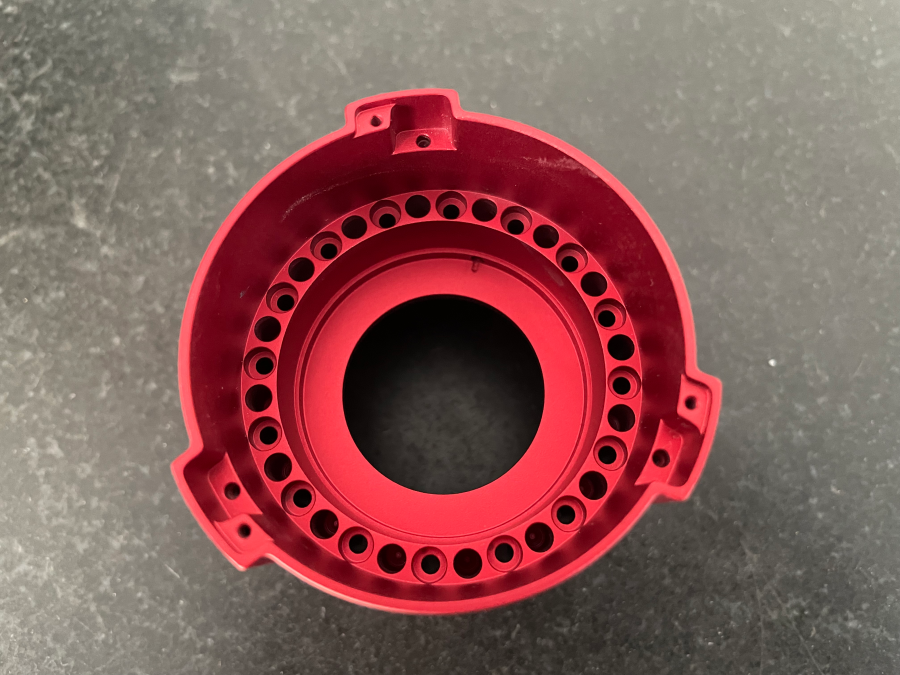

Case Study: GreatLight Metal’s Role in Humanoid Robot Development

A leading robotics company faced challenges in manufacturing actuator housings with:

Complex Geometry: Curved surfaces with internal channels for wiring

Material Requirements: 7075-T6 aluminum for strength-to-weight ratio

Tolerance Specifications: ±0.005mm on bearing bores

Surface Finish: Anodized Type III for corrosion resistance

GreatLight’s Solution:

Design Optimization: Collaborated with the client’s engineers to simplify features without compromising function, reducing machining time by 30%.

5-Axis Machining: Used Beijing Jingdiao machines to cut the part in two setups instead of five, maintaining ±0.003mm accuracy.

In-House Anodizing: Applied hardcoat anodizing to meet the 500-hour salt spray test requirement.

Quality Documentation: Provided full CMM inspection reports and material certificates for each batch.

Result: The client reduced development time by 6 weeks and achieved a 22% cost savings compared to their previous supplier.

Key Considerations When Choosing a CNC Machining Partner

To avoid common pitfalls in precision manufacturing, evaluate suppliers against these criteria:

Equipment Age and Maintenance

Newer machines (≤5 years old) with regular calibration outperform older equipment.

Ask for photos of the machine park—well-maintained facilities reflect operational discipline.

Engineering Support

Does the supplier offer DFM (Design for Manufacturing) feedback before production?

Can they suggest material substitutions or process improvements to reduce costs?

Failure Response Protocol

What happens if a batch fails inspection?

GreatLight offers free rework for quality issues and full refunds if rework is unsatisfactory.

Geographic Advantage

GreatLight’s Dongguan location provides:

Proximity to raw material suppliers (reducing lead times)

Access to skilled technicians (China’s “Hardware Capital”)

Lower operating costs compared to Shenzhen/Shanghai

Five-Axis CNC Machining Services: The Future of Precision Manufacturing

For components requiring the highest precision and complexity, five-axis CNC machining is indispensable. Unlike 3-axis or 4-axis machines, five-axis systems can rotate the cutting tool around two additional axes, enabling:

Single-Setup Machining: Reduces positioning errors from multiple clamping

Improved Surface Finish: Eliminates tool marks on curved surfaces

Access to Undercuts: Machines features inaccessible to conventional mills

GreatLight’s five-axis capabilities are particularly valuable for:

Aerospace: Turbine blades with complex airfoils

Medical: Custom orthopedic implants with organic shapes

Automotive: Transmission housings with internal oil galleries

Conclusion: Why GreatLight Metal Is the Smart Choice for Precision Parts

In the competitive landscape of CNC machining, GreatLight Metal Tech Co., LTD. stands out for its unique blend of technical excellence, process integration, and customer-centric policies. Whether you’re developing prototypes for a startup or manufacturing critical components for a Fortune 500 company, GreatLight offers:

Uncompromising Precision: ±0.001mm tolerance capability with full inspection reporting

Scalable Solutions: From one-off prototypes to 100,000+ piece production runs

Risk Mitigation: Free rework guarantees and ISO-certified quality systems

Industry Expertise: Deep experience in automotive, aerospace, medical, and robotics

To learn more about how GreatLight can accelerate your product development, visit their LinkedIn profile for case studies and client testimonials.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for CNC machining at GreatLight Metal?

A: Lead times vary by complexity:

3-axis CNC prototypes: 3-5 days

4-axis CNC production parts: 7-10 days

5-axis CNC complex components: 10-15 days

Die casting molds: 15-20 days

Q2: How does GreatLight ensure data security for my designs?

A: GreatLight complies with ISO 27001 standards for information security management. All employees sign NDAs, and facility access is restricted via biometric controls. Digital files are stored on encrypted servers with role-based access permissions.

Q3: Can GreatLight machine parts from customer-supplied material?

A: Yes, but this requires prior approval. GreatLight prefers to source material internally to guarantee quality, as customer-supplied material may have inconsistent properties or unknown heat treatment histories.

Q4: What post-processing services are included in the quote?

A: Basic deburring and edge breaking are included. Additional services like anodizing, painting, or plating are quoted separately based on specifications. GreatLight offers package pricing for full turnkey solutions.

Q5: How does GreatLight handle quality disputes?

A: Each part undergoes in-process inspection and final CMM measurement. If a part fails to meet specifications, GreatLight provides:

Free rework within 5 days

Expedited replacement shipping

Full refund if rework is unsatisfactory

Q6: Does GreatLight offer volume discounts?

A: Yes. Pricing scales favorably with quantity:

1-10 pcs: Full prototype pricing

11-100 pcs: 15-25% discount

101-1000 pcs: 25-40% discount

1000+ pcs: Custom negotiated pricing

Q7: What file formats does GreatLight accept for manufacturing?

A: Preferred formats are STEP, IGES, and Parasolid. GreatLight can also work with native CAD files from SolidWorks, Autodesk Inventor, and PTC Creo. 2D drawings (PDF/DXF) are acceptable for simple parts but may require additional engineering review.