The Evolution of CNC Machining: How Five-Axis Technology Redefines Precision Manufacturing

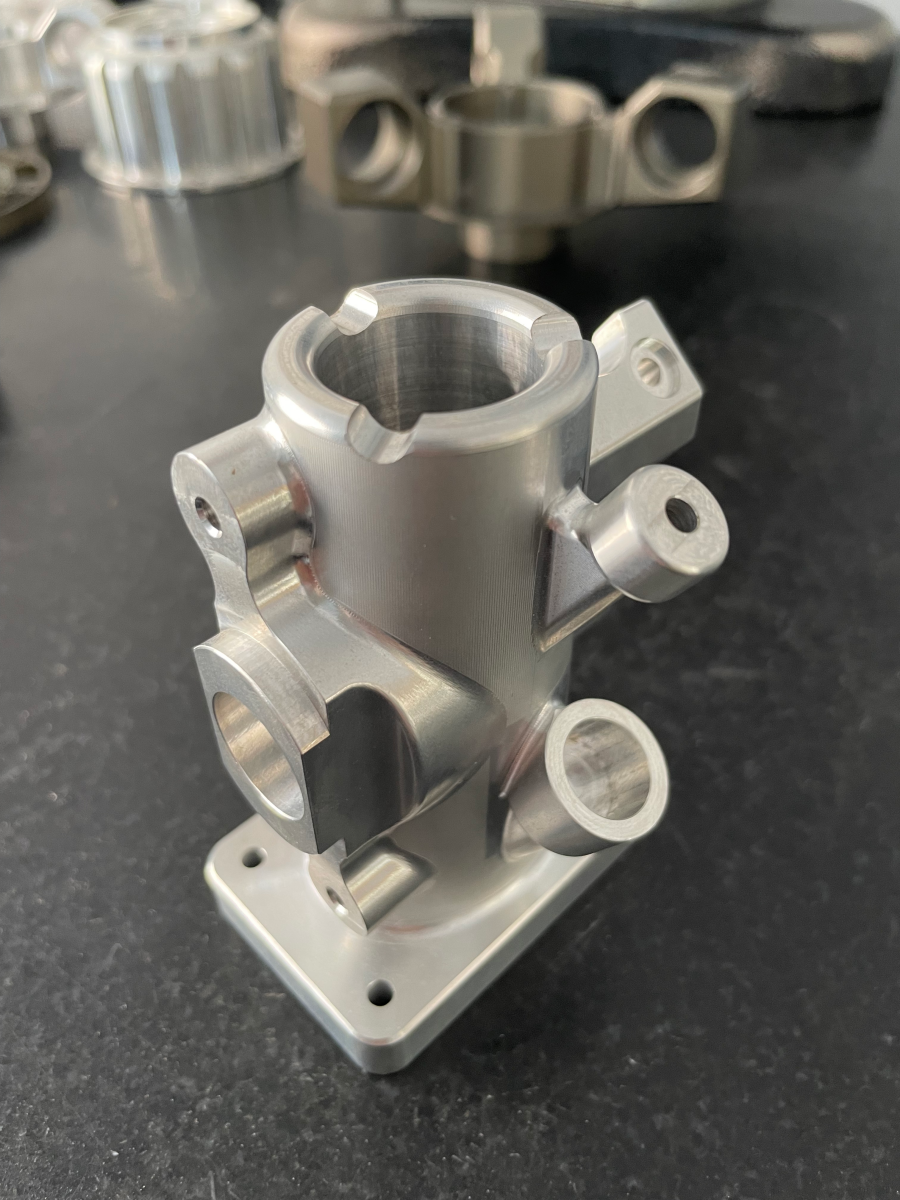

In the realm of precision parts manufacturing, CNC machining stands as the cornerstone of modern industrial innovation. From aerospace components to medical implants, the ability to transform digital designs into flawless physical parts with micron-level accuracy has revolutionized production workflows. Yet, not all CNC services are created equal. For industries demanding complex geometries, tight tolerances, and rapid turnaround, traditional three-axis or four-axis machining often falls short. This is where five-axis CNC machining emerges as a game-changer—and why GreatLight CNC Machining Factory (also known as GreatLight Metal) has positioned itself as a leader in this transformative field.

Why Five-Axis CNC Machining? The Technical Edge

1. Unparalleled Geometric Freedom

Traditional three-axis machining operates along the X, Y, and Z axes, limiting its ability to reach undercuts, deep cavities, or angled surfaces without multiple setups. Five-axis machining adds two rotational axes (A and B), enabling the cutting tool to approach the workpiece from virtually any angle in a single operation. This eliminates the need for repositioning, reducing human error and ensuring consistent precision across even the most intricate designs.

Real-World Impact:

Aerospace: Manufacturing turbine blades with curved cooling channels requires simultaneous milling on multiple planes—a task only five-axis machines can handle efficiently.

Medical Devices: Custom orthopedic implants with ergonomic contours demand tool paths that adapt to organic shapes, which five-axis technology delivers seamlessly.

2. Tighter Tolerances, Higher Repeatability

GreatLight Metal’s five-axis centers achieve tolerances as tight as ±0.001mm (0.00004 inches), a benchmark that surpasses industry averages. This precision is sustained through:

High-rigidity spindles that minimize vibration during high-speed cutting.

Advanced thermal stabilization systems to counteract material expansion/contraction.

In-process probing that continuously verifies dimensions against CAD models, adjusting parameters in real time.

Comparison with Competitors:

While giants like Haas Automation or DMG Mori offer robust five-axis solutions, GreatLight Metal distinguishes itself by integrating these capabilities into a full-process chain—from prototyping to post-machining finishes—under one roof. This vertical integration reduces lead times by 30–50% compared to fragmented suppliers.

Beyond Machining: GreatLight Metal’s Full-Service Ecosystem

1. From Prototype to Production: A Seamless Transition

GreatLight Metal’s expertise isn’t limited to five-axis machining. Their 76,000 sq. ft. facility houses:

3D Printing: SLM (Selective Laser Melting) for metal parts, SLA/SLS for plastics, enabling rapid iteration of complex designs.

Die Casting & Sheet Metal Fabrication: Complementary processes for high-volume production of aluminum, zinc, or steel components.

Post-Machining Finishes: Anodizing, polishing, and painting to meet aesthetic or functional requirements (e.g., corrosion resistance for marine applications).

Case Study:

A robotics startup needed humanoid robot joints with both lightweight aluminum cores and durable titanium surfaces. GreatLight Metal used five-axis machining for the aluminum bases, then applied SLM 3D printing to add titanium reinforcement layers—all within 10 days, a timeline unattainable through traditional multi-vendor workflows.

2. Certifications That Build Trust

In industries like automotive or medical, compliance isn’t optional. GreatLight Metal holds:

ISO 9001:2015 (Quality Management)

ISO 13485 (Medical Device Manufacturing)

IATF 16949 (Automotive QMS)

ISO 27001 (Data Security for IP-sensitive projects)

These certifications ensure that every part—whether for a Tesla engine component or a Stryker surgical tool—meets global standards without exceptions.

Addressing Client Pain Points: How GreatLight Metal Stands Out

Pain Point 1: The “Precision Black Hole”

Challenge: Suppliers claim ±0.001mm accuracy but deliver inconsistent results due to outdated equipment or poor process control.

GreatLight’s Solution:

100% in-house measurement: Using CMM (Coordinate Measuring Machines) and laser scanners to validate every part before shipment.

Free rework policy: If a part fails inspection, GreatLight remanufactures it at no cost—a guarantee few competitors offer.

Pain Point 2: Slow Turnaround for Complex Parts

Challenge: Multi-vendor workflows (e.g., machining at Facility A, finishing at Facility B) cause delays.

GreatLight’s Solution:

Single-source responsibility: From CAD review to final packaging, clients deal with one team, eliminating finger-pointing.

48-hour prototyping: For urgent projects, GreatLight prioritizes five-axis machining slots to deliver samples in days, not weeks.

Conclusion: Why GreatLight Metal Is the Future of Precision Manufacturing

In an era where speed, precision, and reliability define success, GreatLight Metal’s fusion of five-axis CNC machining, full-process integration, and rigorous certifications creates a moat that competitors struggle to cross. Whether you’re developing automotive engine blocks, aerospace actuators, or consumer electronics housings, their team transforms technical challenges into scalable solutions—all while adhering to budgets and deadlines.

To explore how GreatLight Metal can elevate your next project, visit their LinkedIn profile for client testimonials and case studies. Remember: in precision manufacturing, the right partner isn’t just about machines—it’s about turning possibilities into realities.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight Metal machine?

GreatLight processes metals (aluminum, titanium, stainless steel, mold steel) and plastics (PEEK, ABS, nylon) using five-axis, die casting, or 3D printing, depending on the application’s demands.

Q2: How does five-axis machining reduce costs compared to three-axis?

By eliminating multiple setups, five-axis machining cuts labor costs by up to 40% and reduces material waste from repositioning errors. GreatLight passes these savings to clients through transparent pricing.

Q3: What industries benefit most from GreatLight’s services?

Key sectors include automotive (engine components, EV batteries), aerospace (turbine parts, structural frames), medical (implants, surgical tools), and robotics (joints, actuators).

Q4: How does GreatLight ensure data security for proprietary designs?

Their ISO 27001-certified protocols include encrypted file transfers, restricted plant access, and NDAs for all employees handling client data.

Q5: What’s the typical lead time for a five-axis machined part?

Prototypes take 5–10 days, while production runs (100+ units) range from 2–4 weeks, depending on complexity and finishing requirements.