Navigating the Complexities of CNC Machining: Why Five-Axis CNC Machining is Your Key to Precision and Efficiency

In the world of precision parts manufacturing, CNC (Computer Numerical Control) machining stands as a cornerstone technology. From automotive engines to aerospace components, the ability to produce intricate, high-tolerance parts efficiently is critical. However, not all CNC machining services are created equal. For clients seeking unparalleled precision, flexibility, and reliability, five-axis CNC machining emerges as the superior choice—and GreatLight CNC Machining Factory is your ideal partner in this realm.

The Limitations of Traditional 3-Axis and 4-Axis CNC Machining

Before diving into the advantages of five-axis machining, it’s essential to understand the constraints of its predecessors:

3-Axis CNC Machining: This is the most basic form of CNC machining, where the cutting tool moves along three linear axes (X, Y, Z). While suitable for simple, flat parts, it struggles with complex geometries, undercuts, and multi-sided features. Repeated repositioning of the workpiece is often required, leading to longer lead times and potential errors.

4-Axis CNC Machining: Adds a rotational axis (typically the A-axis), allowing the workpiece to rotate during machining. This improves accessibility to some complex features but still has limitations when dealing with highly intricate 3D shapes or parts requiring simultaneous multi-sided machining.

For industries like aerospace, medical devices, and humanoid robotics, where parts often have irregular contours and tight tolerances, these limitations can be deal-breakers. This is where five-axis CNC machining shines.

Why Five-Axis CNC Machining? The Game-Changing Advantages

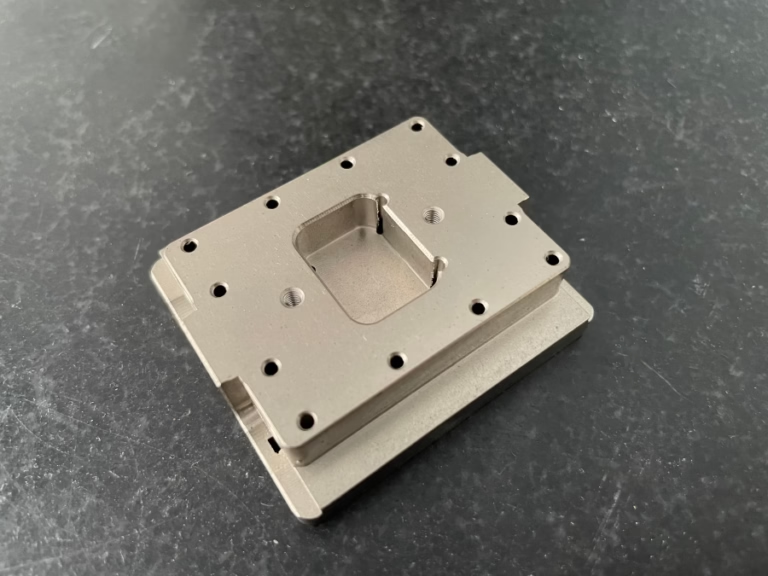

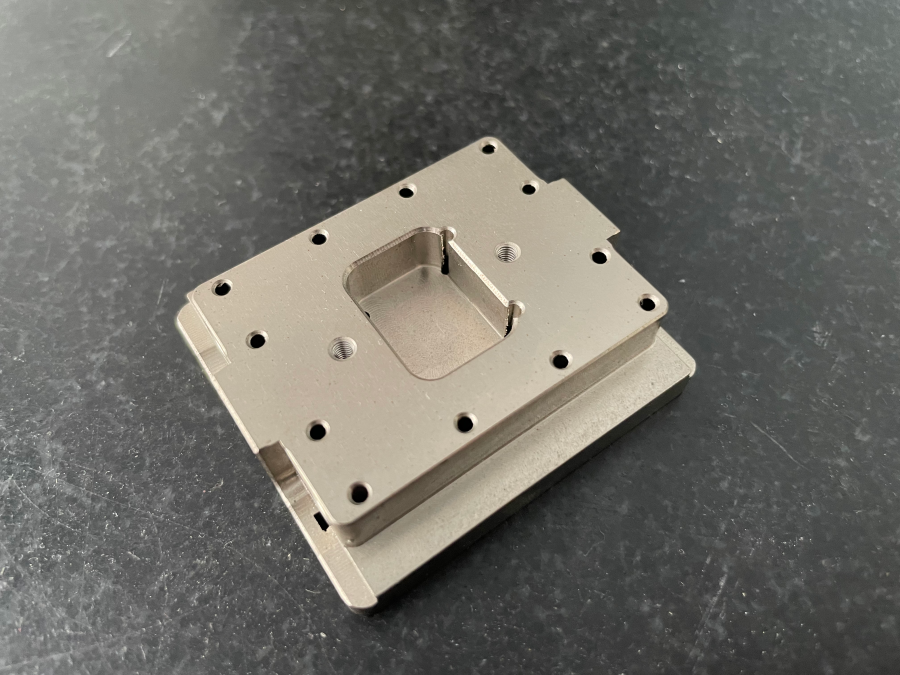

Five-axis CNC machining introduces two additional rotational axes (A and B, or sometimes C), enabling the cutting tool to approach the workpiece from virtually any angle. This capability unlocks several critical benefits:

Unmatched Precision and Surface Finish:

By allowing the tool to maintain optimal cutting angles throughout the operation, five-axis machining minimizes tool deflection and vibration, resulting in superior surface finishes and dimensional accuracy. GreatLight CNC Machining Factory achieves tolerances as tight as ±0.001mm, ensuring your parts meet even the most stringent specifications.

Reduced Setup Times and Increased Efficiency:

Traditional machining methods often require multiple setups to access different sides of a part. Five-axis machining completes complex features in a single setup, slashing lead times and reducing the risk of human error during repositioning.

Ability to Machine Complex Geometries:

From turbine blades to impellers and intricate medical implants, five-axis machining handles parts with compound curves, deep cavities, and undercuts with ease. This makes it indispensable for high-value industries where innovation hinges on geometric complexity.

Improved Tool Life and Cost Savings:

By optimizing cutting angles, five-axis machining reduces tool wear and extends tool life. Fewer tool changes and shorter cycle times translate to lower production costs over the long run.

One-Stop Solution for Prototyping and Mass Production:

Whether you need a single prototype or thousands of production parts, GreatLight CNC Machining Factory leverages its advanced five-axis equipment to deliver consistent quality at scale. Our in-house capabilities include 3D printing, die casting, sheet metal fabrication, and comprehensive post-processing, ensuring a seamless transition from design to finished product.

GreatLight CNC Machining Factory: Your Trusted Partner in Five-Axis Machining

Founded in 2011 in Dongguan’s Chang’an District—China’s hardware and mold capital—GreatLight CNC Machining Factory has evolved from a local workshop into a global leader in precision manufacturing. Here’s why we stand out:

State-of-the-Art Equipment:

Our factory houses 127 pieces of precision machinery, including large high-precision five-axis CNC centers from Dema and Beijing Jingdiao, alongside 4-axis and 3-axis machines, Swiss-type lathes, EDM, and advanced 3D printers (SLM, SLA, SLS). This diverse arsenal allows us to tackle projects of any complexity.

Certified Quality and Compliance:

We adhere to ISO 9001:2015 for quality management, ISO 27001 for data security, ISO 13485 for medical hardware, and IATF 16949 for automotive components. These certifications ensure your parts meet international standards for performance, safety, and reliability.

Engineering Expertise and Full-Process Support:

Our team of 150 skilled professionals provides end-to-end support, from DFM (Design for Manufacturability) analysis to post-processing and finishing. We specialize in custom solutions for humanoid robots, automotive engines, aerospace, and medical devices, offering free rework for quality issues and a full refund if dissatisfied.

Scalability and Speed:

With three wholly-owned manufacturing plants and a 4000mm maximum processing size, we handle both rapid prototyping and high-volume production with equal proficiency. Most projects are completed within days, not weeks.

Case Study: Conquering Complexity in New Energy Vehicle Components

One of our clients, an innovation-driven company in the new energy vehicle sector, faced a critical challenge: manufacturing a complex e-housing with internal cooling channels and tight tolerances. Traditional methods were too slow and prone to errors, jeopardizing their product launch timeline.

GreatLight’s Solution:

Utilized five-axis CNC machining to achieve the intricate cooling channels in a single setup, eliminating the need for multiple fixtures.

Leveraged in-house vacuum casting for low-volume production runs, ensuring cost efficiency without compromising quality.

Delivered 100% compliant parts within 10 days, enabling the client to meet their launch deadlines and secure market share.

This case exemplifies how GreatLight CNC Machining Factory combines technical prowess with agile manufacturing to turn client challenges into success stories.

Conclusion: Choose Precision, Choose GreatLight

In the competitive landscape of precision parts manufacturing, five-axis CNC machining is no longer a luxury—it’s a necessity for staying ahead. Whether you’re developing cutting-edge robotics, automotive components, or aerospace systems, GreatLight CNC Machining Factory offers the expertise, equipment, and certifications to bring your vision to life with unmatched precision and efficiency.

Don’t settle for less. Partner with us today and experience the future of manufacturing. Learn more about our five-axis CNC machining services here.

Frequently Asked Questions (FAQs)

Q1: What industries benefit most from five-axis CNC machining?

A: Five-axis machining is ideal for industries requiring complex, high-precision parts, such as aerospace, medical devices, automotive, robotics, and defense. Its ability to machine intricate geometries in a single setup makes it indispensable for these sectors.

Q2: How does GreatLight ensure part quality and consistency?

A: We adhere to ISO 9001:2015 standards, use advanced in-house measurement equipment (e.g., CMMs), and implement rigorous quality checks at every stage. Our certifications (ISO 13485, IATF 16949) further validate our commitment to excellence.

Q3: Can GreatLight handle both prototyping and mass production?

A: Absolutely. Our flexible manufacturing capabilities allow us to seamlessly transition from rapid prototyping (using 3D printing or CNC) to high-volume production (via CNC machining or die casting), ensuring consistency and cost efficiency.

Q4: What materials can GreatLight machine?

A: We work with a wide range of metals (aluminum, stainless steel, titanium, mold steel) and plastics, offering custom solutions tailored to your material requirements.

Q5: How does GreatLight protect intellectual property (IP) for sensitive projects?

A: We comply with ISO 27001 standards for data security, ensuring your designs and proprietary information are safeguarded throughout the manufacturing process.

Q6: What sets GreatLight apart from other CNC machining suppliers?

A: Unlike many suppliers who focus on a single process, we offer a full-process chain (CNC machining, 3D printing, die casting, sheet metal fabrication) under one roof, backed by international certifications and deep engineering support. This integrated approach reduces lead times, costs, and risks for our clients.

For more insights into our capabilities, visit our LinkedIn page.