How To Make Mini CNC Drawing Machine Arduino Project

In the world of DIY electronics and precision engineering, creating a mini CNC drawing machine using Arduino is an exciting and rewarding project. It combines the principles of computer – numerical control (CNC) with the versatility of Arduino, allowing you to bring your digital designs to life on paper. This blog post will guide you through the steps of making your very own mini CNC drawing machine with an Arduino.

Understanding the Basics

A CNC drawing machine works by precisely controlling the movement of a pen or drawing tool in two or three dimensions according to a set of programmed instructions. Arduino, an open – source electronics platform, serves as the brain of this machine, interpreting the commands and driving the motors to move the pen.

Components Required

Arduino Board: You can choose an Arduino Uno or Mega, depending on your needs. The Uno is a great choice for beginners, while the Mega offers more memory and processing power for more complex projects.

Stepper Motors: These motors are used to control the movement of the pen in the X and Y directions. You’ll typically need two stepper motors for a basic 2D drawing machine.

Stepper Motor Drivers: These drivers are essential for controlling the stepper motors. Popular options include the A4988 or DRV8825.

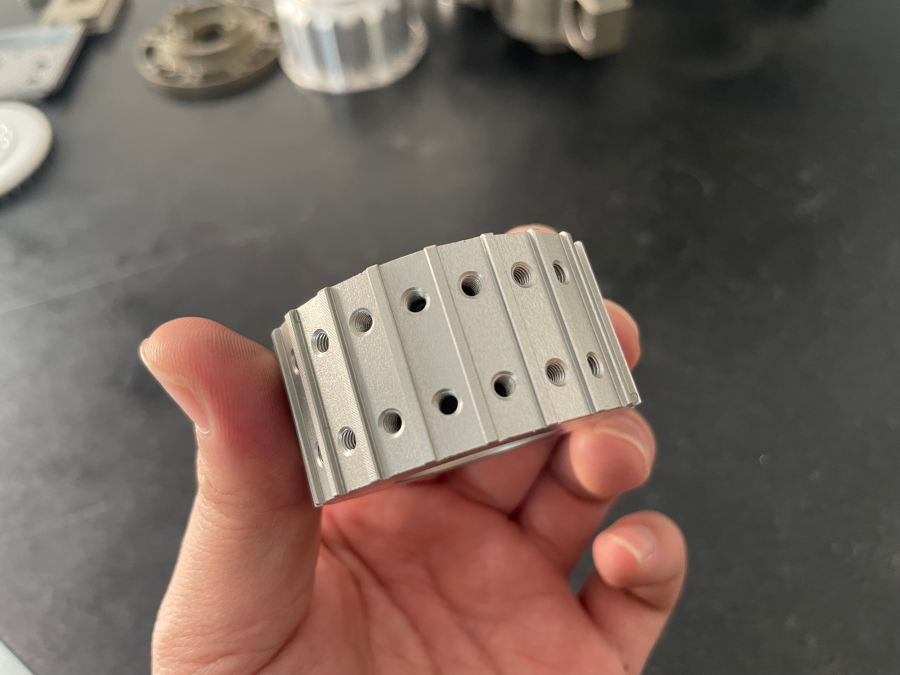

Linear Rails and Bearings: These components are used to guide the movement of the pen holder in a straight line, ensuring accurate drawing.

Pen Holder: You can create a simple pen holder using 3D printing or by using basic materials like plastic or metal.

Power Supply: A suitable power supply is needed to power the Arduino board and the stepper motors. Make sure to choose a power supply with the correct voltage and current ratings.

Building the Structure

Design the Frame: You can design a frame for your CNC drawing machine using materials like wood, acrylic, or aluminum. The frame should provide a stable base for the linear rails and the other components.

Install the Linear Rails: Mount the linear rails on the frame using screws or other fasteners. Make sure the rails are parallel and level to ensure smooth movement.

Attach the Stepper Motors and Drivers: Connect the stepper motors to the stepper motor drivers and then mount them on the frame. Wiring should be done carefully according to the datasheet of the drivers.

Electrical Connections

Connect the Stepper Motor Drivers to Arduino: Connect the control pins of the stepper motor drivers to the digital pins of the Arduino board. This will allow the Arduino to send signals to the drivers, which in turn control the movement of the stepper motors.

Power Supply Connection: Connect the power supply to the Arduino board and the stepper motor drivers. Make sure to follow the correct polarity to avoid damaging the components.

Programming the Arduino

Install the Required Libraries: You’ll need to install libraries for controlling the stepper motors and for communicating with the computer. Popular libraries include the AccelStepper library for stepper motor control.

Write the Sketch: Write a program in the Arduino IDE that reads the input commands and controls the movement of the stepper motors accordingly. You can use G – code, a standard programming language for CNC machines, to define the drawing path.

Testing and Calibration

Initial Testing: After completing the wiring and programming, conduct an initial test to check if the stepper motors are moving as expected. You can use simple test codes to move the motors in small increments.

Calibration: Calibrate the machine to ensure accurate drawing. This may involve adjusting the steps per unit, the acceleration, and the maximum speed of the stepper motors.

Conclusion

Building a mini CNC drawing machine using Arduino is a challenging but highly rewarding project. It not only allows you to gain hands – on experience in electronics, mechanics, and programming but also gives you the ability to create unique and personalized drawings. With the right components, a well – designed structure, and a carefully programmed Arduino, you can build a functional and accurate CNC drawing machine.

Frequently Asked Questions

Can I use a different microcontroller instead of Arduino?

Yes, you can use other microcontrollers like Raspberry Pi or ESP32. However, the programming and wiring may need to be adjusted accordingly.

What kind of pens can I use with the CNC drawing machine?

You can use a variety of pens, such as ballpoint pens, felt – tip pens, or even markers. The choice of pen depends on your drawing requirements and the surface you’re drawing on.

Is it possible to upgrade the machine to 3D drawing?

Yes, it is possible to upgrade the machine to 3D drawing by adding a third stepper motor and a Z – axis linear rail. However, this requires more complex programming and mechanical design.

How accurate can the CNC drawing machine be?

The accuracy of the machine depends on several factors, including the quality of the components, the calibration, and the programming. With high – quality components and proper calibration, you can achieve an accuracy of up to a few hundredths of a millimeter.

Can I use the CNC drawing machine for commercial purposes?

Yes, you can use the machine for commercial purposes, such as creating custom art, signage, or prototypes. However, make sure to comply with all relevant intellectual property and business regulations.