When discussing CNC machining capabilities, the focus often leans towards milling centers. However, the humble yet powerful CNC lathe remains the undisputed champion for producing rotationally symmetric parts. A fundamental question for engineers and purchasers is: how many axis in CNC lathe machine? The answer is not a single number but a spectrum that defines the machine’s complexity, capability, and suitability for specific tasks. From simple two-axis turning to sophisticated multi-tasking centers that blur the line between milling and turning, understanding these configurations is key to selecting the right process for your precision parts.

H2: Deconstructing the Core: Basic Axes in a CNC Lathe

At its most fundamental level, a CNC lathe operates on two primary linear axes relative to the rotating workpiece. These are the backbone of all turning operations.

X-Axis: This axis controls the radial movement of the cutting tool. Movement along the X-axis moves the tool perpendicular to the spindle centerline, determining the diameter of the part being cut. A command in the -X direction brings the tool closer to the center, reducing the diameter.

Z-Axis: This axis controls the longitudinal movement parallel to the spindle centerline. It defines the length of cuts, faces shoulders, and controls the travel along the length of the workpiece.

This 2-axis configuration (X and Z) is the workhorse for classic turning operations like facing, straight turning, tapering, and grooving. The workpiece spins, and the tool moves in these two planes to remove material.

H3: Enhanced Capabilities: The Introduction of Additional Axes

To machine more complex features without multiple setups, additional axes are integrated. This is where capabilities expand dramatically.

1. The C-Axis: Adding Rotational Tool Positioning

What it is: The C-axis is a programmable rotational axis of the spindle itself. In a standard lathe, the spindle rotation (usually called the S-axis for speed) is simply for cutting. With a C-axis, the spindle can be precisely positioned and locked at any angular orientation (e.g., 45.5 degrees).

What it enables: This allows the machine to perform off-center milling and drilling operations using live tools. A live tooling station, often mounted on the turret, is a driven tool that can rotate independently of the spindle. With the workpiece locked in position by the C-axis, the live tool can mill a flat, drill a cross-hole, or cut a keyway. This creates a 3-axis CNC lathe (X, Z, C) often marketed as a “mill-turn” or “turning center with live tooling.”

2. The Y-Axis: Adding True Off-Center Machining

What it is: The Y-axis provides linear movement perpendicular to both the X and Z axes. Essentially, it allows the tool to move radially off-center in a vertical direction.

What it enables: The combination of X, Y, Z, and C axes unlocks true 3D contouring capability on a turned part. The machine can now mill complex contours, eccentric profiles, and features that are not radially symmetric, all in a single setup. This is a major step towards complete part machining.

H3: The Pinnacle of Integration: Multi-Tasking and Multi-Axis Turn-Mill Centers

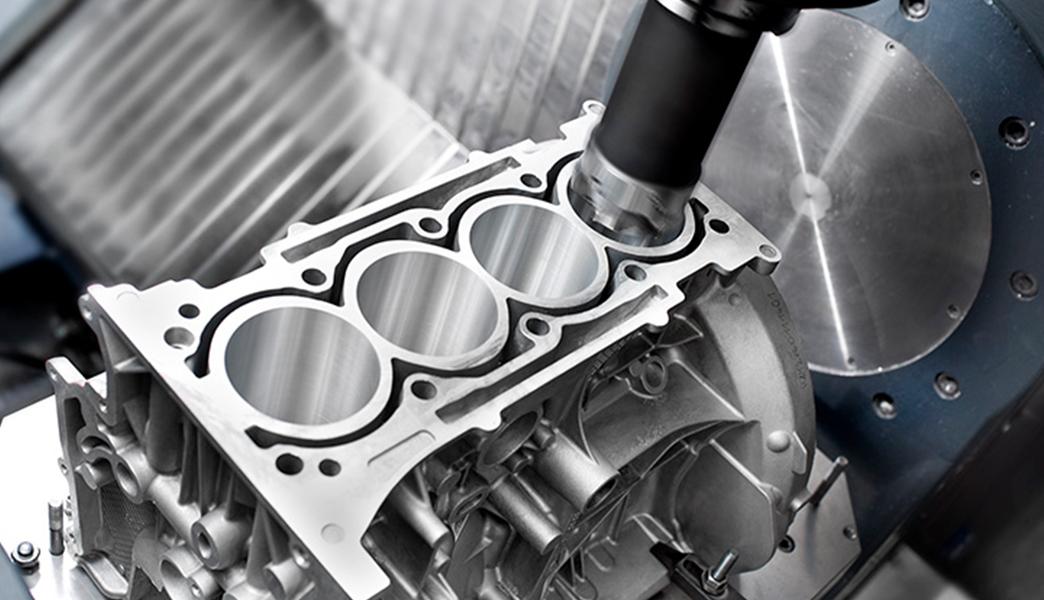

The most advanced lathes are multi-tasking machines (MTM) or turn-mill centers. They integrate additional subspindles, tool systems, and axes to achieve unparalleled functionality.

Second Spindle (or Sub-Spindle): This is essentially a counter-spindle that can pick up the part from the main spindle after the first side is machined. This allows complete machining of both ends of a part in one cycle, eliminating a secondary operation.

B-Axis: On some advanced machines, the tool turret or a dedicated milling head itself may have a B-axis, which is a rotary axis around the Y-axis. This allows the cutting tool to approach the workpiece at compound angles, similar to a 5-axis milling machine.

Resulting Configurations: A high-end multi-tasking machine might be described as having X, Y, Z, B, C axes, plus a main and sub-spindle. This transforms it into a hybrid machine capable of 5-axis simultaneous milling on a rotated part, combined with precision turning, all in one chucking.

H2: Axis Configuration Comparison: From Simple to Complex

The following table summarizes the evolution:

| Configuration | Typical Axes | Key Capability | Ideal For |

|---|---|---|---|

| Standard CNC Lathe | X, Z | Basic turning, facing, grooving | Shafts, pins, bushings, simple rotational parts. |

| Turning Center with Live Tooling | X, Z, C | On-part milling (flats, slots), cross-drilling. | Parts requiring a few off-center features (e.g., a driveshaft with a flat). |

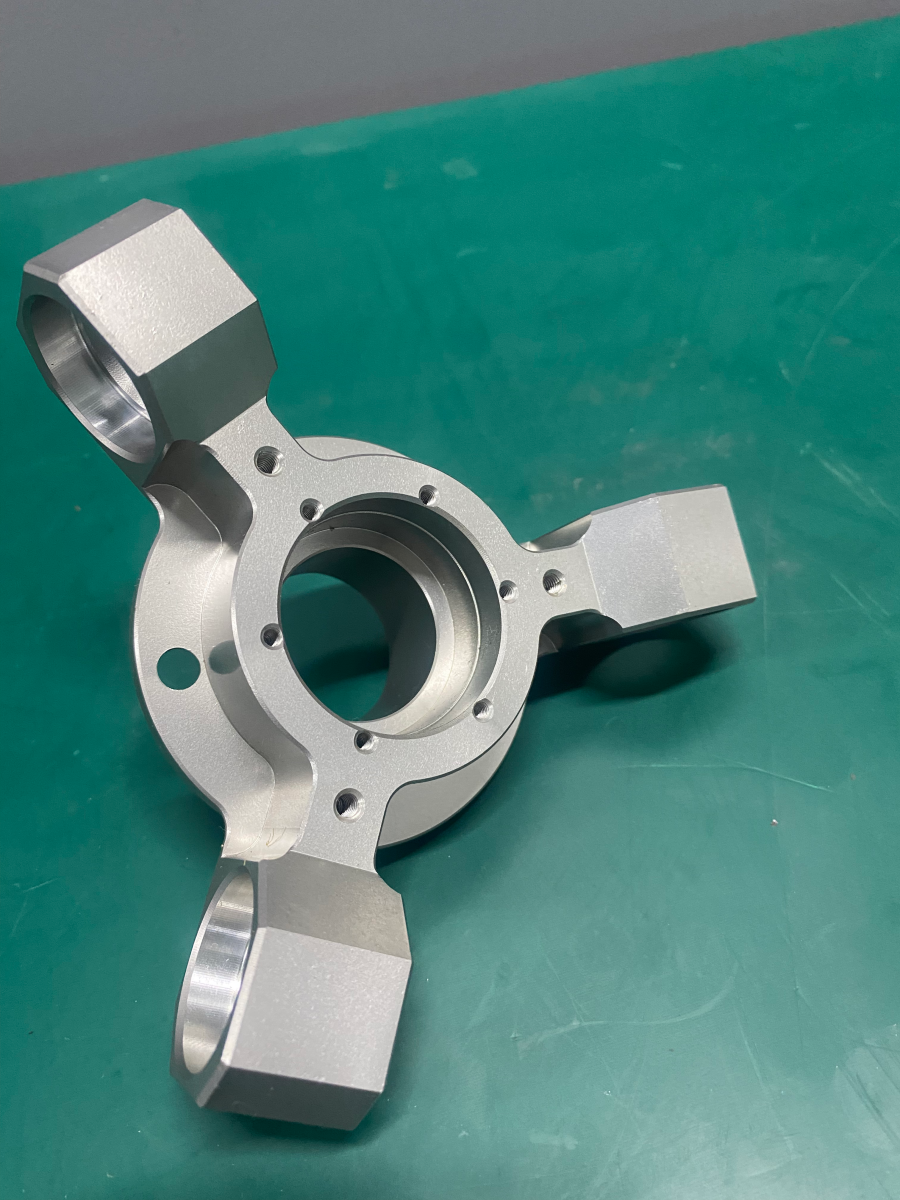

| Y-Axis Turning Center | X, Y, Z, C | Complex off-center milling & contouring. | Parts with eccentric cam profiles, non-radial contours. |

| Multi-Tasking Machine (MTM) | X, Y, Z, B, C + Sub-Spindle | Complete part machining in one setup: turning, 5-axis milling, back-side work. | Highly complex, high-value parts for aerospace, medical, and automotive (e.g., impellers, orthopedic implants, complex fluid fittings). |

H2: Why Axis Count Matters for Your Precision Parts Project

Choosing a supplier with the appropriate axis technology is a critical strategic decision.

Geometric Freedom: More axes mean the ability to produce more complex geometries in a single setup.

Precision & Accuracy: Single-setup machining eliminates the cumulative errors introduced by moving and re-fixturing a part across multiple machines. This is crucial for holding tight tolerances, often as stringent as ±0.001mm.

Lead Time and Cost: Completing a part in one chucking drastically reduces total machining time, handling time, and queue time between operations. This leads to faster overall lead times and can lower total cost despite a potentially higher hourly machine rate.

Feature Integration: It allows for the design of innovative parts that combine turned and milled features in ways that are difficult or impossible to make with separate machines.

For projects demanding the highest level of integration, precision, and efficiency, partnering with a manufacturer equipped with advanced multi-axis turn-mill centers is essential. Companies like GreatLight CNC Machining Factory leverage this advanced equipment, moving beyond basic 2-axis turning to provide comprehensive precision 5-axis CNC machining services that encompass complex mill-turn operations. This full-spectrum capability ensures that whether your part is a simple bushing or a complex hybrid component, it can be manufactured optimally under one roof.

Conclusion

So, how many axis in CNC lathe machine? The journey begins at two (X and Z) and extends to sophisticated systems with five or more axes (X, Y, Z, B, C), integrated spindles, and live tooling. This progression from simple turning to complete multi-tasking machining reflects the evolution of modern manufacturing towards integrated, efficient, and precision-driven solutions. When sourcing precision machined components, understanding your supplier’s lathe capabilities—measured in axes and functionality—is as critical as evaluating their milling expertise. It is this holistic command over the entire machining spectrum, from advanced turning to intricate milling, that defines a truly capable manufacturing partner in today’s competitive landscape.

Frequently Asked Questions (FAQ)

Q1: Is a 2-axis CNC lathe still relevant today?

A: Absolutely. For high-volume production of simple, rotationally symmetric parts (e.g., bolts, simple shafts), a 2-axis lathe is often the most cost-effective and fastest solution. The key is matching the machine’s capability to the part’s complexity.

Q2: What is the main advantage of a Y-axis on a lathe?

A: The primary advantage is the ability to perform true off-center milling and contouring without having to index the part to a specific angle using the C-axis. It enables more efficient machining of complex, non-radial features and provides greater flexibility in tool path generation.

Q3: Can a multi-axis turning center replace a 5-axis CNC milling machine?

A: Not entirely; they are complementary. A multi-axis turn-mill center excels at parts where a significant portion is rotational (“turning dominant”). A dedicated 5-axis milling center is superior for complex prismatic parts with no rotational symmetry. The best manufacturers, like GreatLight Metal, possess both to match the optimal technology to each part’s geometry.

Q4: For a new product prototype with both turned and milled features, what should I look for in a supplier?

A: Prioritize suppliers with multi-axis mill-turn capabilities. This ensures your prototype is made in a single setup, yielding faster turnaround, higher accuracy for fit-testing, and a part that truly reflects the design intent before moving to production.

Q5: How do certifications like IATF 16949 relate to CNC lathe operations?

A: Certifications like IATF 16949 for automotive or ISO 13485 for medical devices govern the entire quality management system. For lathe operations, this means stringent control over the programming, tooling, in-process inspection, and documentation for every turned part, ensuring traceability and consistency crucial for regulated industries. Partners with such credentials, such as GreatLight Metal Tech Co., LTD., provide an added layer of trust for critical applications.