How to Build a Real CNC Machine on the Cheap? The Smart Way to Source Precision Machining Without Breaking the Bank

When it comes to custom precision parts machining, one of the most frequently asked questions is: “How can I build a real CNC machine on the cheap?” Whether you’re a startup, a research lab, a hobbyist, or even an SME trying to validate a prototype before committing to mass production, the desire to reduce costs while maintaining precision is universal.

But here’s the truth: building a fully functional CNC machine in-house from scratch is not only technically challenging but also cost-ineffective for most applications — especially when high precision, tight tolerances (like ±0.001mm), and material versatility are required. That said, there are smart, strategic ways to achieve affordable, reliable CNC machining without compromising on quality. And that’s where expert partners like GreatLight CNC Machining Factory come into play.

Let’s explore the real-world options, trade-offs, and best practices — from DIY CNC builds to outsourcing with high ROI.

🧩 Why Building a CNC Machine Cheaply Is Harder Than It Looks

Before diving into solutions, let’s break down why “building a real CNC machine on the cheap” is often more complex than anticipated:

1. Precision is Expensive

Achieving micron-level accuracy requires high-quality components: linear rails, ball screws, servo or stepper motors with precise encoders, rigid frames, and vibration damping. Cutting corners on these leads to poor repeatability and scrap rates.

2. Software & Control Systems

CNC isn’t just about hardware. You’ll need CAM software, G-code generation, machine controllers (like GRBL, Mach3, or LinuxCNC), and sometimes custom programming — all adding to the learning curve and potential failure points.

3. Material & Tooling Costs

Cutting tools, workholding solutions, and raw materials (metals like aluminum, titanium, or stainless steel) are additional cost centers. Cheaper tooling wears faster and can damage both your parts and your machine.

4. Time & Expertise

Designing, assembling, calibrating, and troubleshooting a CNC machine takes significant engineering know-how. For many businesses, that time is better spent on product development or market entry.

✅ Smarter Alternatives: When to Outsource CNC Machining Instead

Rather than building your own CNC machine, a more efficient and cost-effective approach — especially for precision parts machining — is to partner with a reliable, certified manufacturer that already has the infrastructure, expertise, and quality systems in place.

This is where GreatLight CNC Machining Factory shines.

🔍 Why Choose a Pro Like GreatLight CNC?

Founded in 2011 and headquartered in Chang’an, Dongguan — China’s precision hardware capital — GreatLight CNC Machining Factory isn’t your average machine shop. Here’s what sets them apart:

🏭 State-of-the-Art Facility

7,600 m² factory floor

150+ skilled employees

127 precision CNC machines, including:

5-axis CNC machining centers

4-axis and 3-axis mills

CNC lathes, grinders, EDM machines

3D metal & plastic printers (SLM/SLA/SLS)

🛠️ End-to-End Precision Capabilities

They offer a wide range of services beyond just CNC:

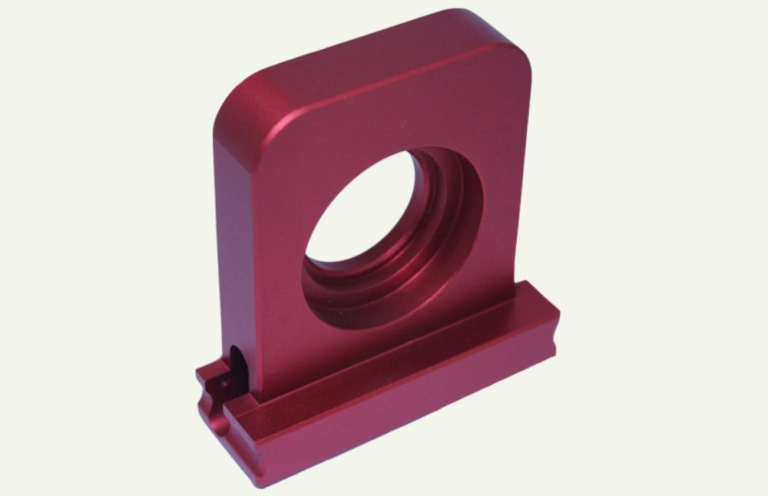

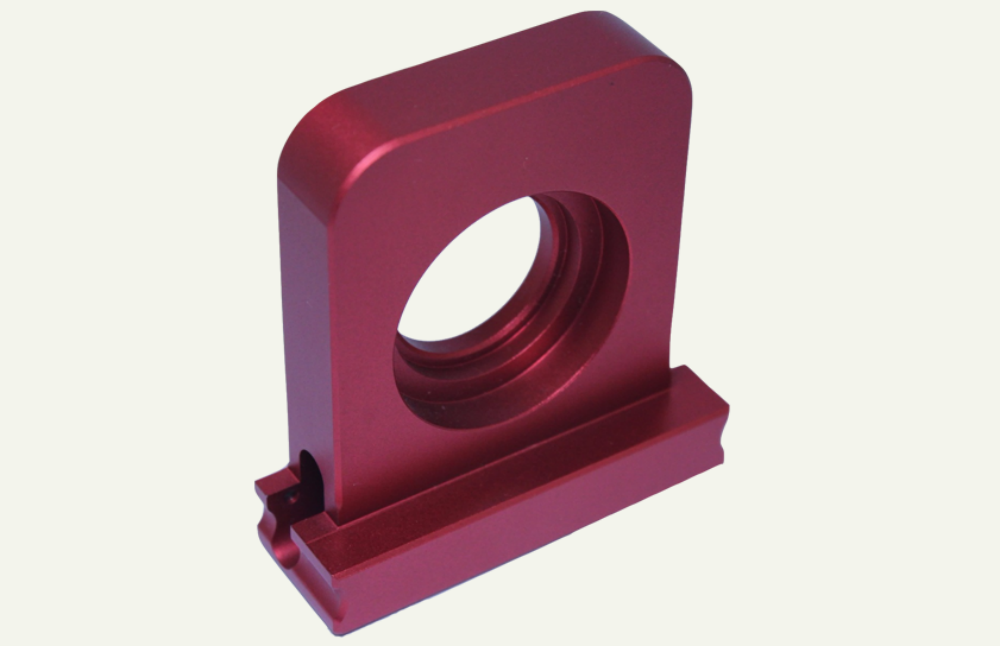

CNC milling & turning

Die casting & mold making

Sheet metal fabrication

Metal & plastic 3D printing (Aluminum, Titanium, Stainless Steel, etc.)

Vacuum casting

Full post-processing & surface finishing

📏 Unmatched Precision & Scale

Tolerances as tight as ±0.001mm

Maximum part size: up to 4000mm

Rapid prototyping in just days, not weeks

🏅 Certified Quality Assurance

ISO 9001:2015 for quality management

IATF 16949 (automotive)

ISO 13485 (medical devices)

ISO 27001 (data security)

💯 Customer-Centric Guarantees

Free rework for quality defects

Full refund if issues persist after rework

IP protection for sensitive projects

Whether you’re designing parts for humanoid robots, aerospace components, or next-gen automotive engines, GreatLight CNC has the technical depth and versatility to deliver.

Explore their 5-axis CNC precision services →

🆚 Building vs. Buying vs. Outsourcing: A Quick Comparison

| Approach | Upfront Cost | Technical Skill Needed | Precision Level | Scalability | Best For |

|---|---|---|---|---|---|

| Building Your Own CNC | $2,000 – $10,000+ | High | Medium to Low (unless using premium parts) | Low | Hobbyists, education, basic prototyping |

| Buying a Used CNC Machine | $5,000 – $50,000 | Medium to High | Medium | Medium | Small workshops, low-volume production |

| Outsourcing to Experts (e.g., GreatLight CNC) | Low MOQs, pay per part | Low | Very High (±0.001mm) | High | Startups, engineers, product developers, OEMs |

🎯 When Does It Make Sense to Build Your Own CNC Machine?

There are a few scenarios where building your own CNC might make strategic sense:

Educational Purposes – Great for learning G-code, motion control, and mechanical design.

Highly Customized One-Off Projects – If you need a very specific motion profile not available in commercial machines.

Long-Term In-House Production – If you have the budget, engineering team, and plan to manufacture hundreds/thousands of identical parts regularly.

Even then, starting with a used professional-grade machine or outsourcing initial runs while you develop your in-house capabilities is often the smarter move.

🧠 Pro Tips for Reducing CNC Machining Costs Without Sacrificing Quality

If your goal is to minimize expenses while still getting precision parts, consider these practical tips when working with a manufacturer like GreatLight CNC:

✔ Optimize Your Design

Minimize the number of setups

Use standard tool sizes

Avoid unnecessary complexity

✔ Choose the Right Material

Aluminum is cost-effective and easy to machine

Stainless steel and titanium are stronger but more expensive

✔ Order in Batches

Economies of scale apply — the more parts you order, the lower the unit cost

✔ Leverage Rapid Prototyping First

Validate your design via 3D printing or a single CNC prototype before full production

🤝 Conclusion: Focus on Precision. Leave the Machine Building to the Experts.

So, how do you build a real CNC machine on the cheap? The most reliable, cost-effective, and precision-driven answer is: you don’t — at least not until you absolutely have to.

Instead, partner with a trusted manufacturer like GreatLight CNC Machining Factory, which offers high-precision 5-axis CNC machining, rapid prototyping, and a full spectrum of post-processing services — all backed by international certifications and years of industry experience.

Whether you’re producing parts for robotics, aerospace, medical devices, or consumer electronics, sourcing from an expert allows you to focus on innovation while they handle the complexities of precision machining.

For high-quality, affordable, and scalable CNC solutions, GreatLight CNC is your best choice. Get started with precision machining today — at the best price and performance.

👉 Connect with GreatLight Metal on LinkedIn for more insights →

❓ Frequently Asked Questions (FAQ)

Q1: Is it really cheaper to outsource CNC machining instead of building my own machine?

Yes, in almost all cases — especially for small to medium production volumes. Outsourcing eliminates the need for expensive equipment purchases, facility costs, maintenance, and skilled labor. You pay only for what you need, when you need it.

Q2: What’s the cheapest way to get precision CNC parts made?

The most economical approach is to work with a reliable CNC machining provider that offers tiered pricing, such as GreatLight CNC. They allow low MOQs, fast turnaround, and provide quotes based on your design files, material, and tolerances.

Q3: Can I build a CNC machine with ±0.001mm accuracy at home?

Technically possible but extremely difficult. Achieving such tight tolerances requires high-end components, perfect assembly, and a controlled environment — factors that are hard to replicate in a DIY setup. Professional shops use calibrated machines and quality systems to ensure consistency.

Q4: What materials can be CNC machined affordably?

Common and cost-effective materials include aluminum (6061, 7075), brass, mild steel, and plastics like ABS or POM. Exotic metals (e.g., titanium, Inconel) cost more but are available for specialized applications.

Q5: How long does CNC machining typically take?

Lead times vary based on part complexity, quantity, and machining method. Simple parts can be produced within 1–3 days, while complex or high-volume orders may take 1–2 weeks. GreatLight CNC specializes in rapid turnaround without sacrificing precision.

By focusing on your core goals and leveraging expert manufacturing partners, you can achieve world-class precision without the headache, risk, or expense of building your own CNC machine from scratch.