Definition of the machining center

The machining center is a highly automated CNC machine tool that can automatically change tools and perform multi-process processing on once-clamped parts. The machining center is composed of mechanical equipment and a CNC system. It has a tool magazine and automatic tool change functions. It can continuously carry out drilling, boring, milling, reaming, tapping and other processes after the workpiece is clamped. This type of machine tool greatly reduces the workpiece clamping time, machine tool measurement and adjustment and other auxiliary process times. It is particularly suitable for processing parts with complex shapes and high precision requirements, as well as small and medium-sized batch production with frequent frequencies. variety changes.

Significant advantages of machining centers

Compared with ordinary CNC machine tools, machining centers have the following significant advantages:

Process concentration: The machining center is equipped with a tool magazine and can automatically change tools. It can carry out multi-process processing after clamping, which improves processing efficiency and precision.

Strong adaptability to object processing: The flexible production of the machining center enables it to quickly respond to special requirements and achieve mass production, thereby improving market competitiveness.

High processing precision: Through centralized processing procedures and reduced human interference, the machining center can provide higher processing precision and more stable processing quality.

High machining productivity: The tool magazine and automatic tool changer of the machining center reduce the workpiece clamping and setting time and improve the cutting utilization rate of the machine tool, which is generally 3-4 times that of ordinary machine tools.

Reduced operator work intensity: The machining center has a high degree of automation, and the operator is mainly responsible for the operation and monitoring of the program, thereby reducing heavy manual operations.

High economic benefits: Although the equipment cost of the machining center is relatively high, other expenses can be saved in single-part and small batch production, and production costs can be reduced by reducing the scrap rate.

Conducive to the modernization of production management: The machining center helps to simplify the inspection process and management work and promotes the modernization of production management.

These advantages of machining centers make them the preferred equipment for efficient and precise processing in modern manufacturing.

What are the main components of a machining center?

The machining center is an efficient CNC machine tool that integrates a variety of processing functions and can perform milling, drilling, tapping and other operations. The main components of the machining center include:

Basic components: including the bed, column and worktable, which form the structural basis of the machining center and support static and dynamic loads.

Spindle component: It consists of spindle housing, spindle motor, spindle and spindle bearing. It is the output power component of cutting processing, and its precision directly affects the processing quality.

CNC system: including CNC device, programmable logic controller (PLC), servo motor system and control panel, responsible for executing the processing program and controlling the precise movement of the machine tool.

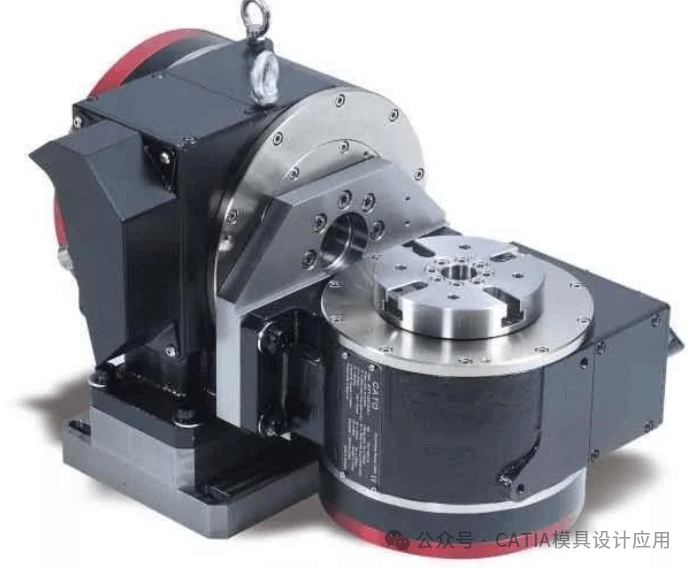

Automatic tool changing system: It consists of a tool magazine, a manipulator and a drive mechanism, enabling automatic replacement of tools during processing to improve production efficiency.

Auxiliary devices: including lubrication, cooling, chip evacuation, protection, hydraulic, pneumatic and detection systems, etc., to ensure the normal operation of the machining center and the stability of the processing environment .

These components work together to enable the machining center to achieve high efficiency and high precision automated processing.

What types of machining tasks are machining centers suitable for?

A machining center is an efficient and precise CNC machine tool suitable for a variety of complex machining tasks. It is particularly suitable for processing the following types of parts:

Box-type parts: These parts generally have several systems of internal holes and cavities. The machining center can complete most or all processes in a single clamping, ensuring accuracy and consistency of quality.

Complex surfaces: Machining centers are capable of processing parts composed of complex curves and surfaces, especially parts commonly found in aerospace, automotive, and other industries, such as wheels and propellers.

Special-shaped parts: Parts with irregular shapes, such as brackets and forks, can be processed by the machining center through multi-station mixing, reducing the number of tools and processing cycles.

Disc, Sleeve, and Plate Parts: These parts can contain keyways, radial holes, end hole systems, and curved surfaces, and machining centers can efficiently handle these features.

Parts put into production periodically: The machining center can store programs and parameters, so that repeated production of the same parts can start quickly and the production cycle can be shortened.

Precision parts: The high-precision characteristics of machining centers make them suitable for aerospace, medical equipment and other fields, which have extremely high requirements for dimensional accuracy and surface quality of parts .

The versatility and level of automation of machining centers make them indispensable equipment in modern manufacturing, which can significantly improve production efficiency and processing quality.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.