Navigating Precision Manufacturing: Why GreatLight Metal Stands Out in a Competitive Field

In today’s fast-paced manufacturing landscape, precision is not just a requirement—it’s a competitive edge. As industries from aerospace to medical devices demand ever-higher levels of accuracy and reliability, the choice of a CNC machining partner becomes critical. While many suppliers claim cutting-edge capabilities, few can consistently deliver on promises of ultra-precision, rapid turnaround, and comprehensive service. This is where GreatLight CNC Machining Factory distinguishes itself as a leader in five-axis CNC machining and integrated manufacturing solutions.

The Precision Predicament: Common Challenges in CNC Machining

Before diving into why GreatLight Metal excels, let’s examine the core pain points that plague many R&D teams and procurement engineers:

1. The “Precision Black Hole”

Many suppliers advertise extreme tolerances (e.g., ±0.001mm), but in practice, inconsistencies emerge due to outdated equipment, unstable processes, or lack of rigorous quality control. This leads to costly rework or, worse, failed inspections downstream.

2. The “Speed vs. Quality” Dilemma

Balancing rapid prototyping with maintaining high precision is a persistent challenge. Suppliers may rush production, sacrificing accuracy for deadlines, or vice versa.

3. Hidden Costs and Communication Barriers

Unexpected fees for tooling, revisions, or post-processing often inflate budgets. Additionally, poor communication between designers and machinists can result in misaligned expectations.

4. Data Security Risks

For projects involving proprietary designs or intellectual property, inadequate data protection protocols can expose clients to significant risks.

5. Limited Material and Process Expertise

Not all suppliers can handle complex materials (e.g., titanium alloys, medical-grade plastics) or advanced processes like hybrid CNC-3D printing.

GreatLight Metal: Engineering Trust Through Technology and Certification

Founded in 2011 in Dongguan’s Chang’an District—a hub for precision hardware—GreatLight CNC Machining Factory has evolved from a local workshop into a globally trusted partner. Its rise is rooted in four pillars:

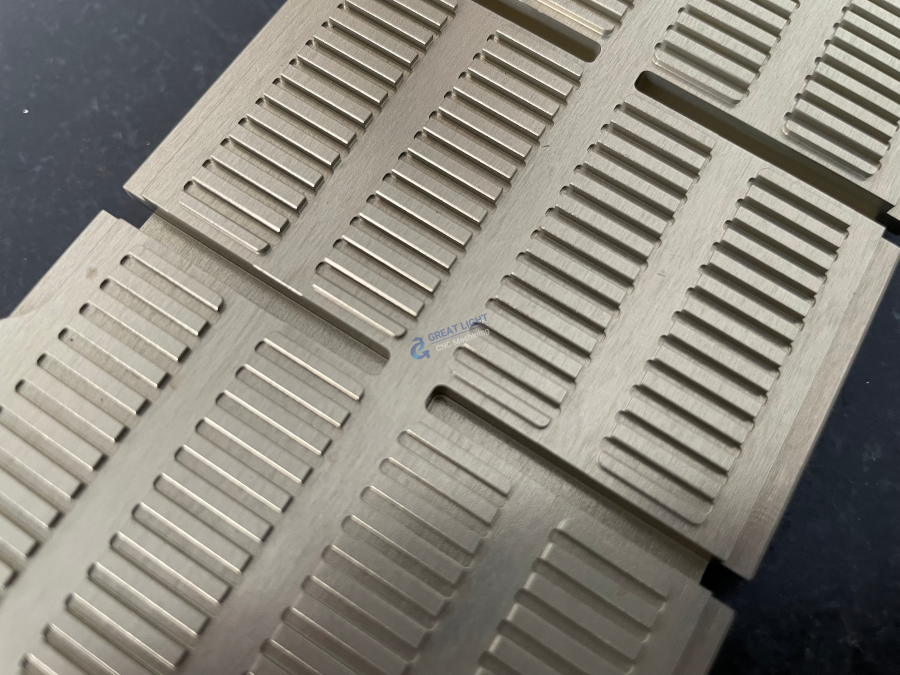

1. Advanced Equipment and Process Capabilities

GreatLight operates 127 pieces of precision equipment, including:

High-end five-axis CNC centers (Dema, Beijing Jingdiao) for complex geometries.

Multi-axis turning/milling machines for tight tolerances.

EDM, grinding, and 3D printing (SLM, SLA, SLS) for hybrid manufacturing.

Large-scale vacuum forming for prototyping.

This diverse arsenal allows seamless handling of materials from aluminum alloys to medical-grade stainless steel, with maximum processing dimensions of 4000mm and precision down to ±0.001mm.

2. Authoritative Certifications

GreatLight adheres to ISO 9001:2015 for quality management, ISO 13485 for medical hardware, and IATF 16949 for automotive components. These certifications ensure compliance with global standards, reducing risk for clients.

3. Full-Process Chain Integration

Unlike niche suppliers, GreatLight offers end-to-end solutions:

Precision CNC machining (3/4/5-axis).

Die casting and sheet metal fabrication.

3D printing (metal and plastic).

Post-processing (polishing, anodizing, heat treatment).

This integration minimizes handoffs, accelerates timelines, and ensures consistency.

4. Deep Engineering Support

GreatLight’s team of 150 professionals includes mechanical engineers, quality inspectors, and project managers who collaborate closely with clients to optimize designs for manufacturability, reducing costs and lead times.

Case Studies: Real-World Impact

1. Automotive: Conquering Complex E-Housing Challenges

A client developing electric vehicle components required lightweight, high-strength housings with intricate cooling channels. Traditional methods struggled with wall thickness consistency. GreatLight’s five-axis CNC machining and SLM 3D printing produced parts with ±0.005mm tolerance, reducing weight by 30% and cutting lead time by 50%.

2. Medical: Precision Implants for Orthopedic Surgery

A medical device firm needed titanium alloy implants with biocompatible surfaces. GreatLight’s ISO 13485-certified process combined CNC milling with electropolishing, achieving a surface roughness of Ra < 0.1μm and passing FDA validation on the first attempt.

3. Aerospace: Satellite Component Prototyping

For a satellite manufacturer, GreatLight machined aluminum 6061-T6 brackets with micro-threads (M1.2) and tight positional tolerances. Using high-speed five-axis machining, they delivered 50 prototypes in 7 days, meeting stringent vibration and thermal stability requirements.

Why Choose GreatLight Over Competitors?

While suppliers like Hytek, Protolabs, or Xometry offer CNC services, GreatLight differentiates itself through:

| Factor | GreatLight Metal | Hytek/Protolabs/Xometry |

|---|---|---|

| Precision | ±0.001mm guaranteed | Typically ±0.005mm–0.010mm |

| Certifications | ISO 9001, 13485, IATF 16949 | Limited to ISO 9001 in most cases |

| Process Integration | Full chain (CNC, die casting, 3D print) | Niche focus (e.g., Protolabs on 3D print) |

| Data Security | ISO 27001-compliant | Varies by supplier |

| Cost Efficiency | Competitive pricing for high-mix runs | Higher for low-volume orders |

FAQs

Q1: What materials can GreatLight machine?

GreatLight handles metals (aluminum, stainless steel, titanium, brass) and plastics (ABS, PC, PEEK), as well as composites and ceramics.

Q2: How does GreatLight ensure quality?

Every part undergoes in-process inspection (CMM, laser scanning) and final QA checks against 3D models. Non-conformances trigger free rework or refunds.

Q3: What is the typical lead time?

Prototypes take 3–5 days; low-volume production (10–100 parts) ships in 7–10 days. Rush orders are prioritized.

Q4: Does GreatLight protect IP?

Yes. All projects are governed by NDAs, and facilities are ISO 27001-compliant to safeguard digital assets.

Q5: Can GreatLight handle large parts?

Absolutely. Their five-axis machines accommodate parts up to 4000mm in length, ideal for aerospace or industrial components.

Conclusion: Elevate Your Precision Manufacturing with GreatLight

In an industry where compromises on precision or reliability can derail entire projects, GreatLight CNC Machining Factory stands as a beacon of consistency, innovation, and trust. By combining cutting-edge five-axis CNC technology (learn more here), global certifications, and a client-centric approach, they empower engineers and manufacturers to turn ambitious designs into flawless reality.

For those seeking a partner that transcends “just machining” to deliver true engineering value, GreatLight is the clear choice. Explore their capabilities and case studies on LinkedIn and take the first step toward precision excellence.