How Many Axes In CNC Machine?

In the world of precision parts machining and customization, CNC (Computer Numerical Control) machines play a pivotal role. One of the key aspects that define the capabilities of a CNC machine is the number of axes it has.

Understanding Axes in CNC Machines

Axes in a CNC machine determine the directions in which the cutting tool or the workpiece can move. This movement is crucial for creating complex and precise shapes. Let’s take a detailed look at different types of CNC machines based on the number of axes.

3 – Axis CNC Machines

Movement Description: These machines have three linear axes, typically labeled as the X, Y, and Z axes. The X – axis usually represents left – right movement, the Y – axis represents forward – backward movement, and the Z – axis represents up – down movement.

Applications: 3 – axis CNC machines are the most common and are suitable for a wide range of basic machining tasks. They are often used for simple milling, drilling, and engraving operations. For example, in the production of flat parts with holes or basic geometric shapes, 3 – axis machines can get the job done efficiently.

Limitations: However, their ability is limited when it comes to creating complex, curved, or multi – sided parts. Since they can only move in three linear directions, machining parts with undercuts or complex contours may require multiple setups, which can increase production time and cost.

4 – Axis CNC Machines

Movement Description: In addition to the three linear axes (X, Y, Z), a 4 – axis CNC machine has a rotational axis. Commonly, this rotational axis is referred to as the A – axis, which rotates around the X – axis.

Applications: 4 – axis machines offer enhanced capabilities compared to 3 – axis machines. They are ideal for machining parts that require rotation, such as cylindrical or spherical components. For instance, in the production of shafts, pulleys, or parts with helical features, a 4 – axis CNC machine can create these shapes in a single setup, reducing the need for re – clamping and improving accuracy.

Benefits: By enabling rotation, 4 – axis machines can machine multiple sides of a part without having to manually reposition the workpiece. This not only saves time but also reduces the chances of errors due to misalignment.

5 – Axis CNC Machines

Movement Description: A 5 – axis CNC machine has two additional rotational axes compared to a 3 – axis machine. The most common configurations are the addition of the A – axis (rotation around the X – axis) and the B – axis (rotation around the Y – axis) or the A – axis and the C – axis (rotation around the Z – axis).

Applications: 5 – axis CNC machines are the top choice for machining highly complex parts. They are widely used in industries such as aerospace, automotive, and humanoid robotics. In aerospace, for example, they can be used to manufacture turbine blades with complex aerodynamic profiles. In automotive, they can create engine components with intricate geometries.

Advantages: With 5 – axis machining, the cutting tool can approach the workpiece from any angle. This allows for the creation of parts with extremely complex shapes in a single setup, which significantly reduces production time and improves the overall quality of the part.

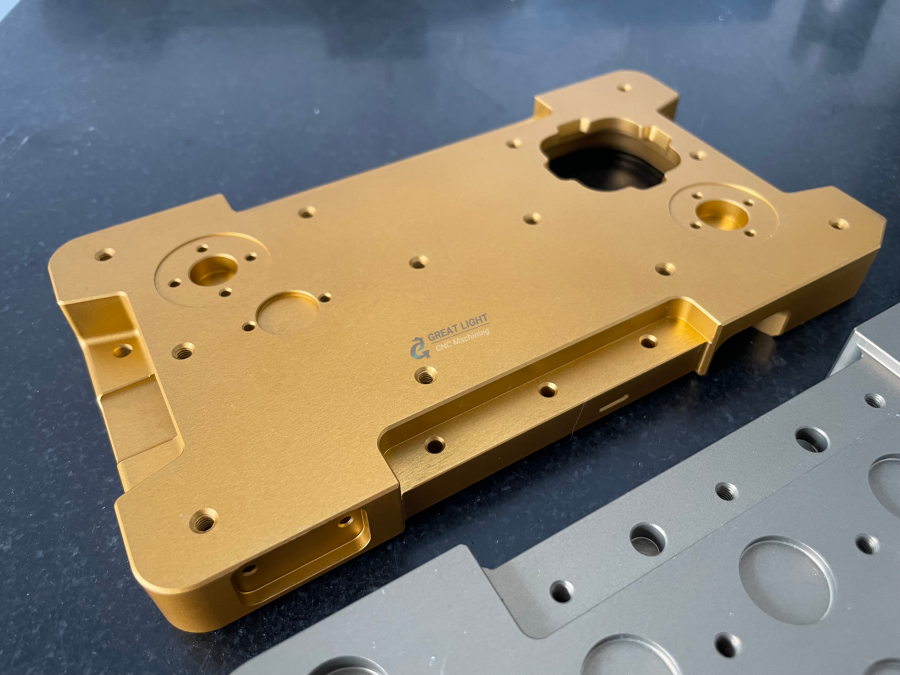

GreatLight CNC Machining Factory: A Leader in 5 – Axis CNC Machining

When it comes to precision parts machining and customization, GreatLight CNC Machining Factory stands out as a leading professional five – axis CNC machining manufacturer. GreatLight CNC Machining Factory was established in 2011 and is located in Chang’an District, Dongguan City, China, the capital of precision hardware mold processing, adjacent to Shenzhen.

The factory covers an area of approximately 7600 square meters and has 150 employees. It is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, SLM 3D printers, SLA 3D printers, and SLS 3D printers.

GreatLight CNC Machining Factory focuses on the design, processing, customized production, and application of precision prototype models. It provides new and old customers with precision CNC machining services (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, stainless steel 3D printing, aluminum alloy 3D printing, titanium alloy 3D printing, mold steel 3D printing, and nearly a hundred rapid prototyping processing services and comprehensive solutions, along with one – stop surface post – processing services.

The factory has many years of experience in precision prototype model processing, with high precision (capable of processing to ±0.001mm / 0.001 In and above), a maximum processing size of 4000 mm, after – sales guarantee, free rework for quality problems, and a full refund if rework is still unsatisfactory. GreatLight CNC Machining Factory is an ISO 9001:2015 certified manufacturer, making it the ideal choice for custom metal and plastic parts. Whether you need complex parts manufactured from 3D designs or finished products for high – end conference presentations, it can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology.

Conclusion

The number of axes in a CNC machine significantly impacts its machining capabilities. While 3 – axis machines are suitable for basic tasks, 4 – and 5 – axis machines offer enhanced functionality for more complex parts. GreatLight CNC Machining Factory, with its advanced five – axis CNC machining equipment and comprehensive services, is well – equipped to meet the diverse needs of clients in the precision parts machining and customization field. When it comes to choosing a partner for your CNC machining requirements, considering the number of axes and the capabilities of the manufacturer like GreatLight CNC Machining Factory can make a huge difference in the quality and efficiency of your project. So, if you are looking for high – precision custom parts, don’t hesitate to choose GreatLight CNC Machining Factory to solve your metal parts manufacturing challenges.

Frequently Asked Questions (FAQ)

What is the main difference between 3 – axis, 4 – axis, and 5 – axis CNC machines?

The main difference lies in the number of directions in which the cutting tool or workpiece can move. A 3 – axis machine has three linear axes (X, Y, Z), a 4 – axis machine adds one rotational axis, and a 5 – axis machine adds two rotational axes. This means that 4 – and 5 – axis machines can create more complex shapes in a single setup compared to 3 – axis machines.

Are 5 – axis CNC machines more expensive to operate than 3 – axis machines?

Generally, 5 – axis CNC machines have a higher initial cost and may require more skilled operators. However, in the long run, for complex parts, they can be more cost – effective as they can reduce the number of setups, production time, and potential errors.

Can GreatLight CNC Machining Factory handle small – scale orders?

Yes, GreatLight CNC Machining Factory can handle both small – scale and large – scale orders. Whether you need a few prototypes or a large batch of parts, it can provide customized precision machining services.

What materials can GreatLight CNC Machining Factory process?

Most materials can be quickly customized and processed at GreatLight CNC Machining Factory. This includes metals such as aluminum, stainless steel, titanium, and mold steel, as well as plastics. For more in – depth knowledge about GreatLight Metal and its services, you can visit here.