In the realm of precision engineering, the question “What do you make with a CNC machine?” transcends basic functionality—it’s about unlocking possibilities for industries that demand uncompromising accuracy, efficiency, and innovation. For over a decade, GreatLight CNC Machining Factory has redefined the boundaries of CNC machining by integrating five-axis technology, full-process manufacturing, and ISO-certified quality systems to serve clients across automotive, aerospace, medical, and robotics sectors. Let’s explore how CNC machines—and specifically GreatLight’s expertise—are shaping the future of high-precision part production.

H2: The Core Capabilities of CNC Machining: From Prototypes to Mass Production

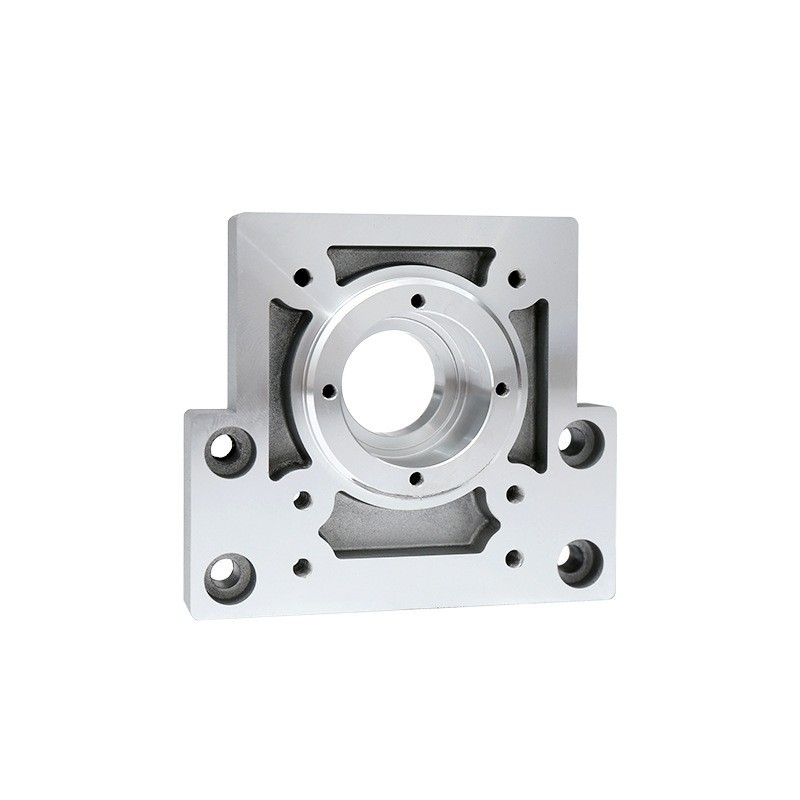

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized controls to operate machine tools, enabling the production of complex parts with tight tolerances. At GreatLight, this technology is elevated through three-axis, four-axis, and five-axis CNC systems, each serving distinct purposes:

Three-axis CNC machining: Ideal for flat or simple 3D parts (e.g., brackets, housings).

Four-axis CNC machining: Adds rotational capability for cylindrical or contoured surfaces (e.g., camshafts, turbine blades).

Five-axis CNC machining: The pinnacle of precision, enabling simultaneous movement along five axes to machine intricate geometries in a single setup (e.g., aerospace components, humanoid robot joints).

GreatLight’s five-axis CNC machining stands out by achieving ±0.001mm accuracy and handling parts up to 4000mm in size, making it indispensable for industries where errors are unacceptable, such as medical implants or satellite components.

H2: Industries Transformed by GreatLight’s CNC Solutions

1. Automotive: Driving Innovation in Engine and Electric Vehicle (EV) Components

The automotive industry demands parts that withstand extreme temperatures, pressures, and wear. GreatLight’s CNC expertise supports:

Engine components: Cylinder heads, crankshafts, and turbocharger housings machined to micro-level precision.

EV innovations: Battery housings, motor casings, and thermal management systems optimized for lightweight yet durable materials like aluminum and titanium.

Case Study: A leading EV manufacturer partnered with GreatLight to produce complex e-motor housings with internal cooling channels. Using five-axis CNC machining, GreatLight reduced lead times by 40% while maintaining ±0.005mm tolerances, enabling the client to accelerate their product launch.

2. Aerospace: Precision Under Pressure

Aerospace parts must meet stringent standards for safety and performance. GreatLight’s ISO 9001:2015 and IATF 16949 certifications ensure compliance with aviation and automotive quality norms, supporting:

Turbine blades: Machined from nickel-based alloys to withstand 1,500°C temperatures.

Structural components: Lightweight titanium brackets for satellites and aircraft frames.

Why GreatLight? Unlike competitors like Protolabs or Xometry, which focus on rapid prototyping, GreatLight combines prototyping with scalable mass production, offering a seamless transition from R&D to full-scale manufacturing.

3. Medical: Where Precision Saves Lives

Medical devices require biocompatible materials and flawless finishes. GreatLight’s ISO 13485 compliance guarantees adherence to medical-grade standards for:

Surgical instruments: Stainless steel forceps with mirror-polished surfaces.

Orthopedic implants: Custom titanium hip joints machined to match patient anatomy.

Trust Factor: GreatLight’s in-house vacuum casting and 3D printing complement CNC machining, enabling rapid iteration of medical prototypes without compromising on quality.

4. Robotics: Enabling Humanoid Agility

Humanoid robots demand parts that mimic human motion—lightweight, strong, and precisely articulated. GreatLight’s five-axis CNC machining excels in:

Robotic joints: Aluminum alloy components with integrated sensors for smooth movement.

End-effectors: Custom grippers tailored to specific tasks, such as handling delicate electronics.

Competitive Edge: While firms like Fictiv specialize in low-volume robotics parts, GreatLight’s 127-piece equipment arsenal and 150-strong team ensure consistent quality even at high volumes.

H2: Beyond Machining: GreatLight’s Full-Process Advantage

CNC machining is just one piece of the puzzle. GreatLight distinguishes itself by offering end-to-end services that eliminate the need for multiple vendors:

Post-processing: Anodizing, plating, and laser etching for aesthetic and functional finishes.

Quality assurance: In-house CMM (Coordinate Measuring Machine) inspections and ISO-compliant documentation.

Material versatility: From metals (aluminum, titanium, stainless steel) to plastics (PEEK, Ultem) and composites.

Example: A client in the drone industry required carbon fiber-reinforced parts with embedded metal threads. GreatLight’s hybrid approach—combining CNC machining for metal inserts and vacuum casting for carbon fiber shells—delivered parts 30% lighter than traditional designs.

H2: Why Choose GreatLight Over Other Suppliers?

The precision machining landscape includes giants like Foxconn Technology Group and niche players like Hass Machine Works. Here’s why GreatLight stands out:

| Factor | GreatLight CNC Machining Factory | Competitors |

|---|---|---|

| Certifications | ISO 9001, IATF 16949, ISO 13485, ISO 27001 | Varies (often fewer industry-specific certs) |

| Equipment | 127+ high-precision machines (5-axis to 3D printers) | Typically fewer 5-axis systems |

| Scalability | Prototypes to 10,000+ units | Often limited to low-volume runs |

| Data Security | ISO 27001-compliant for IP-sensitive projects | Rarely mentioned |

| Location | Dongguan, China (hardware manufacturing hub) | Often in higher-cost regions |

H2: Conclusion: Your Partner for Precision, From Concept to Reality

CNC machines are the backbone of modern manufacturing, but their true power lies in the expertise of those who wield them. GreatLight CNC Machining Factory has spent over a decade mastering this craft, combining five-axis technology, ISO-certified processes, and a full-service ecosystem to deliver parts that meet—and exceed—the most demanding specifications. Whether you’re designing a cutting-edge robot, a life-saving medical device, or a high-performance automotive component, GreatLight’s five-axis CNC machining services are your gateway to precision without compromise.

Ready to elevate your manufacturing? Explore our case studies to see how we’ve solved complex challenges for clients worldwide, or request a quote today to experience the GreatLight difference.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine?

A: We work with metals (aluminum, titanium, stainless steel, brass), plastics (PEEK, ABS, PC), and composites. Our equipment supports both hard-to-machine and exotic materials.

Q2: How does GreatLight ensure part accuracy?

A: We use ISO-certified processes, in-house CMM inspections, and advanced toolpath optimization software. Our five-axis machines reduce setup errors by machining complex geometries in one pass.

Q3: What is the typical lead time for CNC machining?

A: Prototypes take 3–7 days, while production runs (100–10,000+ units) require 2–4 weeks, depending on complexity. Rush orders are available upon request.

Q4: Does GreatLight offer design assistance?

A: Yes! Our engineering team provides DFM (Design for Manufacturing) feedback to optimize parts for cost, machinability, and performance.

Q5: How does GreatLight protect intellectual property (IP)?

A: We adhere to ISO 27001 standards, including NDAs, secure data transmission, and restricted plant access for sensitive projects.