Where Can I Access A CNC Machine?

In the world of precision parts machining and customization, CNC (Computer Numerical Control) machines play a pivotal role. They are the workhorses that transform raw materials into intricate and precise components used in a wide range of industries, from aerospace to automotive and beyond. However, the question for many is, “Where can I access a CNC machine?” Let’s explore various options and look at why GreatLight CNC Machining Factory stands out as an excellent choice.

Manufacturing Service Providers

One of the most common ways to access a CNC machine is through manufacturing service providers. These companies are equipped with a variety of CNC machines and have the expertise to operate them. They offer custom machining services, allowing you to get the exact parts you need. GreatLight CNC Machining Factory is a prime example of such a service provider. GreatLight CNC Machining Factory is a professional five – axis CNC machining manufacturer established in 2011 and located in Chang’an District, Dongguan City, China. It covers an area of approximately 7600 square meters and has 150 employees. With 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, it can handle a wide range of machining projects.

Educational Institutions

Many technical schools, community colleges, and universities offer access to CNC machines as part of their engineering and manufacturing programs. If you are a student or have access to these institutions, you may be able to use their facilities for learning purposes or even for small personal projects. However, the availability may be limited, and there may be strict rules and supervision in place.

Maker Spaces and Fab Labs

Maker spaces and fab labs are community – based facilities that provide access to various manufacturing tools, including CNC machines. These places are designed to foster innovation and creativity, allowing individuals from all walks of life to access advanced manufacturing equipment. You typically pay a membership fee to use these facilities, and they often offer training and support to help you operate the machines safely and effectively.

Renting or Leasing

Some companies specialize in renting or leasing CNC machines. This option can be beneficial if you only need a CNC machine for a short – term project or if you want to test a machine before making a large investment. However, you need to consider factors such as maintenance, training, and the cost of rental.

Why Choose GreatLight CNC Machining Factory

GreatLight CNC Machining Factory offers several advantages that make it a top choice for accessing CNC machining services:

Advanced Equipment and Technology

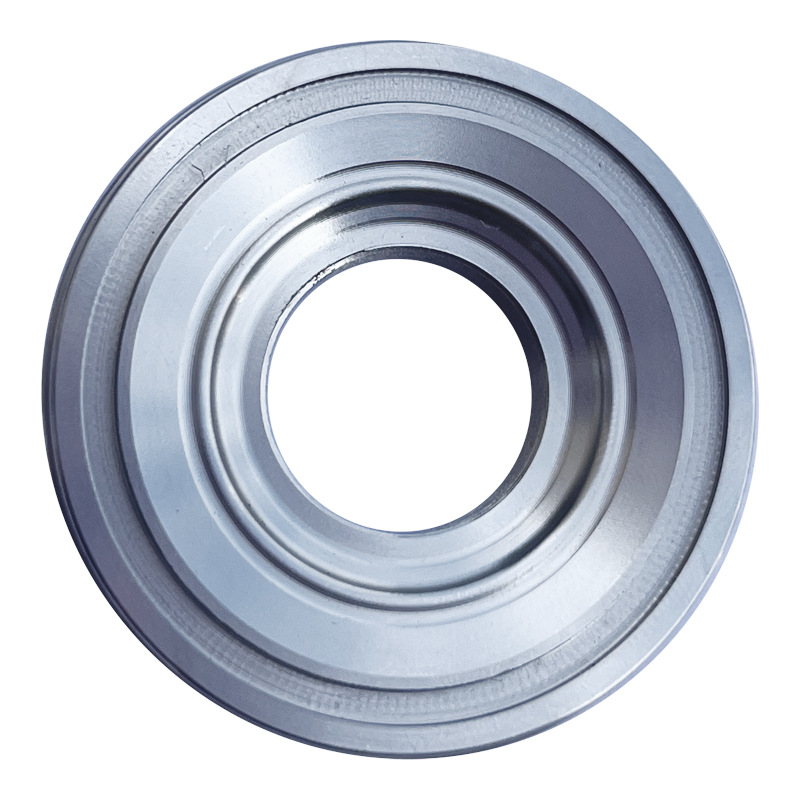

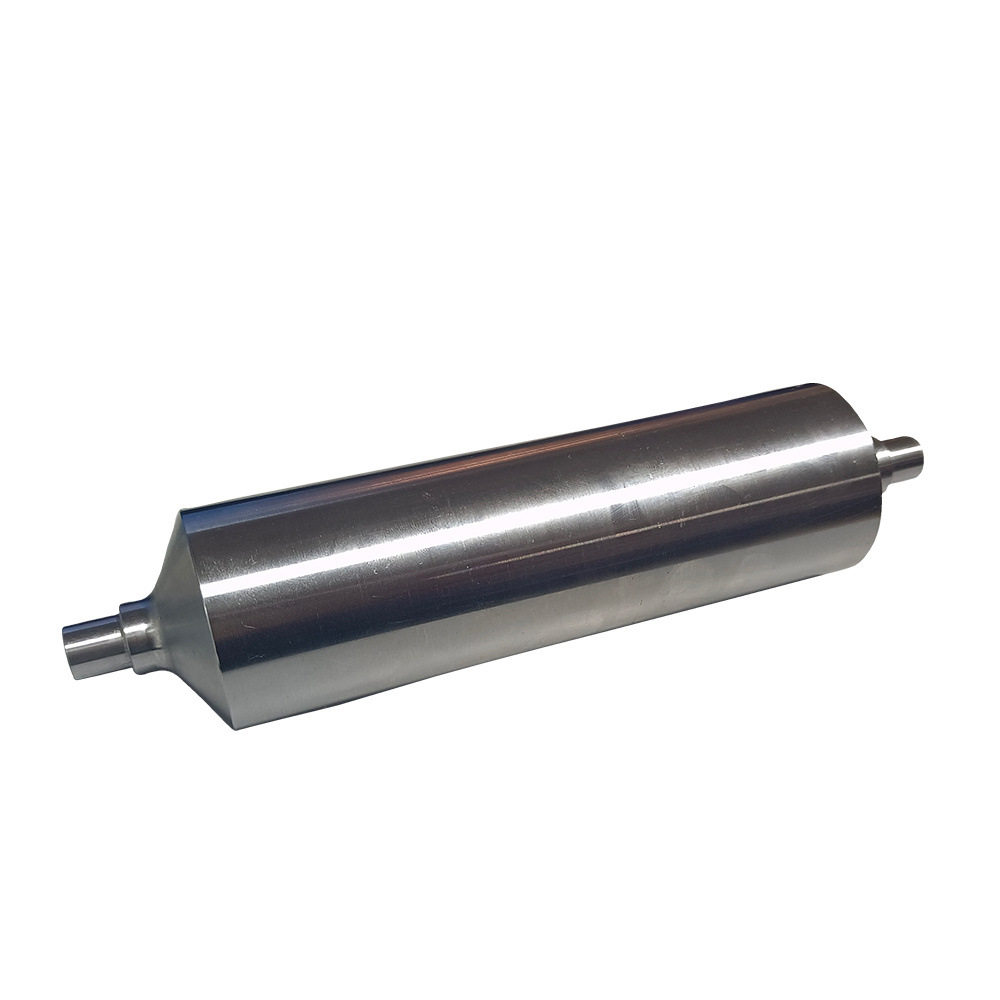

As mentioned earlier, the factory is equipped with a wide range of advanced CNC machines, including five – axis CNC machining centers. These machines can handle complex geometries and high – precision requirements, ensuring that your parts are manufactured to the highest standards.

Comprehensive Services

The factory provides one – stop post – processing and finishing services. In addition to precision CNC machining (three – axis, four – axis, and five – axis machining), it also offers CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, and various 3D printing services. This means you can get all your machining needs met in one place.

Quality Assurance

GreatLight CNC Machining Factory strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. It has in – house precision measurement and testing equipment to verify that all materials and parts meet your specifications. With high precision (capable of processing to ±0.001mm / 0.001 In and above) and a maximum processing size of 4000 mm, you can be confident in the quality of the parts you receive.

Industry Experience

With many years of experience in precision prototype model processing, the factory has a deep understanding of the challenges and requirements of different industries. It has successfully customized metal parts for humanoid robots, automotive engines, aerospace, and other fields, demonstrating its ability to handle diverse and complex projects.

Conclusion

When it comes to accessing a CNC machine, there are multiple options available, including manufacturing service providers, educational institutions, maker spaces, and renting or leasing. However, if you are looking for a reliable, experienced, and comprehensive solution for your precision parts machining and customization needs, GreatLight CNC Machining Factory is an excellent choice. It combines advanced equipment, technical expertise, and strict quality control to provide high – quality parts at a competitive price. Whether you need complex parts manufactured from 3D designs or finished products for high – end conference presentations, GreatLight CNC Machining Factory can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology. So, if you are wondering where to access a CNC machine, consider GreatLight CNC Machining Factory as your go – to partner.

Frequently Asked Questions (FAQ)

What materials can GreatLight CNC Machining Factory process?

Most materials can be quickly customized and processed at GreatLight CNC Machining Factory. This includes metals like aluminum, steel, titanium, and various alloys, as well as plastics and other engineering materials.

What is the minimum order quantity?

The minimum order quantity can vary depending on the specific project requirements. It is best to contact the factory directly to discuss your needs and get a clear answer.

How long does it take to complete a project?

The production time depends on the complexity and size of the project. The factory can quickly produce prototypes and parts within days, but for larger production runs, the lead time may be longer. You can get a more accurate estimate by providing the detailed specifications of your project.

Does the factory offer design services?

GreatLight CNC Machining Factory focuses on the design, processing, customized production, and application of precision prototype models. This indicates that they may offer some level of design support, especially in optimizing designs for manufacturing. You can inquire with them about your specific design needs.

How can I ensure the confidentiality of my design?

GreatLight CNC Machining Factory’s data security is compliant with ISO 27001 standards, which is designed to protect intellectual property. They have measures in place to ensure the confidentiality of your designs and information. For more details, you can refer to their official information or contact them directly. Learn more about GreatLight on LinkedIn