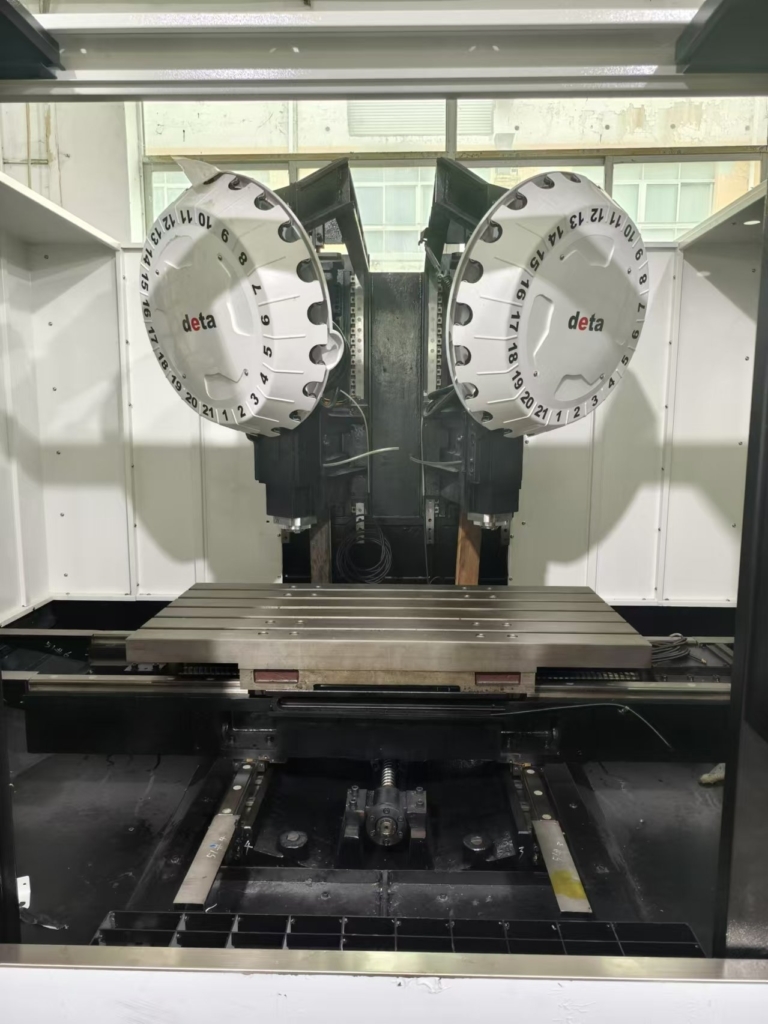

What are the development prospects for twin-spindle machining centers? Double pinmachining centerAs an efficient and precise machine tool equipment, it plays an increasingly important role in the manufacturing industry. Its development prospects seem very broad, mainly reflected in the following aspects:

1. Improve production efficiency

The dual spindle machining center can process two workpieces at the same time, or process both sides or different parts of a single workpiece, thereby greatly shortening the machining cycle. This parallel processing method not only improves production efficiency, but also effectively reduces the processing cost per unit product.

2. Flexibility and versatility

The dual spindle machining center can adapt to different types of processing needs, whether it is small batch customization or mass production, it can easily handle it. In addition, by changing tools and fixtures, machine tools can quickly adapt to different processing tasks, improving the flexibility and response speed of the production line.

3. High precision processing

The dual spindle machining center takes stability and precision into account in its structural design and can maintain good machining accuracy at high speeds. Since both spindles can work together on the same equipment, the number of clamping and movement of the workpiece is reduced, thereby reducing error accumulation and improving processing accuracy.

4. Wide range of applications

The double spindle machining center is suitable for processing a variety of materials, including aluminum alloy, stainless steel, plastic, etc. Whether in the fields of automobile manufacturing or mold manufacturing, it can exert its special advantages to meet the needs of different customers.

5. Technological innovation

With the continuous advancement of technology, twin-spindle machining centers are also constantly innovating and progressing. Modern twin-spindle machining centers already feature higher processing speeds, greater rigidity and more precise control systems. Some advanced models are also equipped with automatic tool changing systems, automatic process adjustment and online inspection functions, further improving the processing capabilities and automation level of the equipment.

6. Market demand

With the development of the manufacturing industry, the demand for efficient and precise processing equipment continues to increase. The double spindle machining center can meet this demand and therefore has broad application prospects in the market. The application of dual spindle machining centers will become more and more widespread, especially in the automobile, electronics and other industries.

In summary, the development prospects of twin-spindle machining centers are very optimistic. With the continuous advancement of technology and the in-depth expansion of applications, dual spindle machining centers are expected to play a more important role in a wider range of fields and further contribute to the transformation and upgrading of industry. manufacturing industry.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.