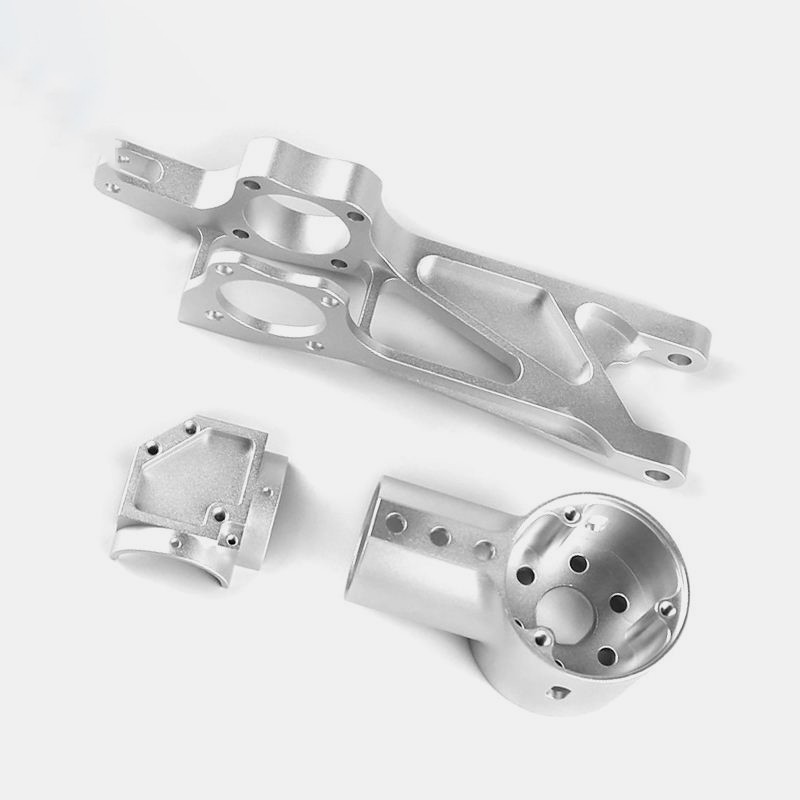

In the world of precision manufacturing, the journey from a raw block of material to a finished, intricate component begins long before the first cutting tool engages. One of the most critical, yet often underestimated, steps in this journey is how to setup workpiece on CNC machine. This process, known as workholding and fixturing, is the literal foundation upon which all machining accuracy, repeatability, and safety are built. A poorly secured workpiece can lead to catastrophic tool failure, scrapped parts, dimensional inaccuracies, and even operator hazards. Conversely, a meticulously planned and executed setup is the hallmark of a professional CNC machining service, ensuring that the sophisticated capabilities of 5-axis CNC machining are fully realized in the final product.

At GreatLight CNC Machining Factory, we view workpiece setup not as a mere preparatory step, but as a fundamental engineering discipline. Our decade-long experience has taught us that the secret to holding tolerances within ±0.001mm lies as much in the setup as in the machine tool itself.

H2: The Critical Prelude: Pre-Machining Preparation

Before a workpiece even touches the machine table, a series of deliberate decisions and preparations set the stage for success.

Blueprint Analysis: Every setup begins with the part drawing. Engineers analyze geometric features, tolerance bands, surface finish requirements, and material specifications. This determines the optimal orientation for machining, the sequence of operations, and identifies critical datums.

Material Selection & Preparation: The workpiece blank must be suitably sized, with enough stock material for machining all features. For materials like aluminum or stainless steel, pre-machining steps such as stress-relieving or ensuring flat and parallel reference surfaces might be necessary.

Strategy Formulation: Will the part require one setup or multiple setups? For complex geometries, leveraging 5-axis CNC machining capabilities can allow for complete machining in a single setup, eliminating cumulative errors from re-positioning.

H2: Choosing the Right Workholding Method: A Toolbox of Solutions

There is no one-size-fits-all solution. The choice of workholding is dictated by the part’s geometry, batch size, required precision, and material. Here’s a breakdown of common methods:

H3: Standard Fixturing: Versatility and Speed

Machine Vises: The workhorse of CNC milling. High-precision hydraulic or pneumatic vises offer consistent clamping force and are ideal for prismatic parts. Soft jaws, custom-machined to fit the workpiece contour, provide superior grip and accuracy.

Modular Fixturing: Systems like tombstones, angle plates, and grid plates allow for multiple parts to be set up simultaneously, drastically improving throughput for small to medium batch production—a common scenario in our rapid prototyping and bridge production services.

Step Clamps and T-Nuts: Used for securing large or irregularly shaped blocks directly to the machine table. Their simplicity and flexibility make them indispensable for one-off or low-volume jobs.

H3: Advanced & Custom Solutions for Complex Challenges

Custom Machined Fixtures: For high-volume production or extremely complex, delicate parts (common in aerospace or medical device components), a dedicated fixture is designed and manufactured. This fixture locates and holds the part with pinpoint accuracy, often incorporating quick-change mechanisms.

Vacuum Chucks: Ideal for thin, flat workpieces like plates or sheets where clamping from the top is not feasible. They distribute holding force evenly across the bottom surface, preventing distortion.

Magnetic Chucks: Used primarily for ferromagnetic materials in grinding or certain milling operations. They provide a uniform, unobstructed holding surface.

H4: The Role of 5-Axis in Workholding Simplification

A significant advantage of 5-axis CNC machining is its ability to reduce workholding complexity. By allowing the cutting tool to approach the workpiece from virtually any angle, features that would traditionally require multiple fixtures and setups can often be completed in one. This not only saves time but, more importantly, enhances overall part accuracy by maintaining a single, constant datum reference throughout the machining process.

H2: The Art of Alignment and Datum Establishment

Securing the part is only half the battle; positioning it correctly within the machine’s coordinate system is the other. This involves establishing the part’s datums (reference points/planes) as the program’s zero points.

Indicating & Tramming: Using a dial indicator, the fixture or workpiece is carefully aligned to ensure it is parallel and square to the machine’s axes of motion. Any misalignment here will be directly translated into part error.

Edge Finding & Probing: Modern CNC machines are often equipped with touch probes. An edge finder or probe is used to precisely locate the workpiece edges or specific datum features. These measured positions are then used to set the work coordinates (G54, G55, etc.) in the machine control.

Tool Setting: Simultaneously, the length and diameter of each tool in the carousel are measured using a tool setter. This data compensates for tool geometry, ensuring the program runs relative to the correct tool tips.

H2: Verification and the First-Article Check

Even with perfect setup, verification is non-negotiable.

Dry Run: The CNC program is run without the workpiece or with the tool offset raised to visually verify tool paths and clearances.

First-Article Inspection: The first part off the machine undergoes a rigorous inspection using coordinate measuring machines (CMMs) or high-precision micrometers. At GreatLight CNC Machining Factory, this step is integral to our IATF 16949 and ISO 13485 compliant processes, especially for automotive and medical components. Only after this part confirms all dimensions are within print tolerance does the production run proceed.

H2: Common Pitfalls and How to Avoid Them

Insufficient Clamping Force: Causes part movement or vibration (“chatter”), leading to poor surface finish and tool wear.

Excessive Clamping Force: Can distort thin-walled or delicate parts, causing accuracy errors that only appear after unclamping.

Improper Datum Sequencing: Failing to machine datums in a logical order can propagate errors through subsequent operations.

Neglecting Thermal Effects: Machining generates heat. For ultra-high precision work, allowing for thermal equilibrium or implementing coolant strategy is part of the setup consideration.

Conclusion

Understanding how to setup workpiece on CNC machine reveals that precision manufacturing is a symphony of interconnected processes. It’s a discipline that balances engineering knowledge, practical experience, and meticulous attention to detail. The setup is the critical interface between the digital design world and the physical part, and its integrity dictates the success of the entire operation.

For projects where setup complexity, material challenges, or micron-level precision are paramount, partnering with an experienced manufacturer is not just an option—it’s a necessity. GreatLight CNC Machining Factory brings its full spectrum of capabilities—from advanced 5-axis CNC machining and custom fixture design to stringent quality management systems—to bear on every workpiece setup. We ensure that your part is not just held, but is perfectly positioned and secured to become a flawless realization of your design.

Frequently Asked Questions (FAQ)

Q1: How do you determine the best workholding method for my part?

A: Our engineering team conducts a DFM (Design for Manufacturability) analysis based on your 3D model and drawings. We consider the part’s geometry, material, required tolerances, surface finish, and production volume. For prototype or low-volume parts, we often leverage modular or standard fixturing for speed and cost-effectiveness. For complex or high-volume production, we may recommend and design a custom fixture to optimize accuracy and cycle time.

Q2: Can you machine a part completely in one setup?

A: This is one of the premier advantages of 5-axis CNC machining. By allowing the cutting tool to access five sides of a part in a single clamping, we can often complete complex geometries in one setup. This eliminates errors from re-positioning and significantly improves overall accuracy and lead time. Our team will assess your part to determine if a single-setup strategy is feasible and optimal.

Q3: My part has very thin walls and is prone to distortion. How do you handle such setups?

A: Delicate parts require specialized strategies. We employ techniques such as using low-stress clamping systems (e.g., vacuum chucks or custom support fixtures), optimizing machining sequences to balance internal stresses, using sharp tools with minimal cutting force, and implementing in-process measurements to monitor for deflection. Our experience with aerospace and medical components makes us well-versed in handling such challenges.

Q4: How much time does the setup typically add to the overall machining time?

A: Setup time varies dramatically. A simple part in a standard vise might take 15-30 minutes. A complex part requiring a custom fixture and precise alignment on a 5-axis machine could take several hours. However, a proper setup saves exponentially more time during the machining run by preventing errors, crashes, and rework. We provide transparent time estimations as part of our project quotation.

Q5: What quality checks are performed on the fixture itself?

A: Any custom fixture manufactured in-house is treated as a precision tool. It is machined to high tolerances and undergoes inspection on a CMM to verify all locating pins, surfaces, and critical dimensions match the design intent. This ensures the fixture will accurately and repeatably position your workpiece for production.