Precision Meets Innovation: How GreatLight CNC Machining Factory Redefines High-End Parts Manufacturing

In the rapidly evolving landscape of precision parts manufacturing, the ability to translate complex designs into flawless physical components is the ultimate competitive edge. For R&D teams, hardware startups, and industrial engineers, the journey from concept to mass production is fraught with challenges—dimensional inaccuracies, material inconsistencies, and production delays can derail even the most promising projects. This is where five-axis CNC machining emerges as a game-changer, and GreatLight CNC Machining Factory stands out as a leader in this domain.

Why Five-Axis CNC Machining? The Technical Edge

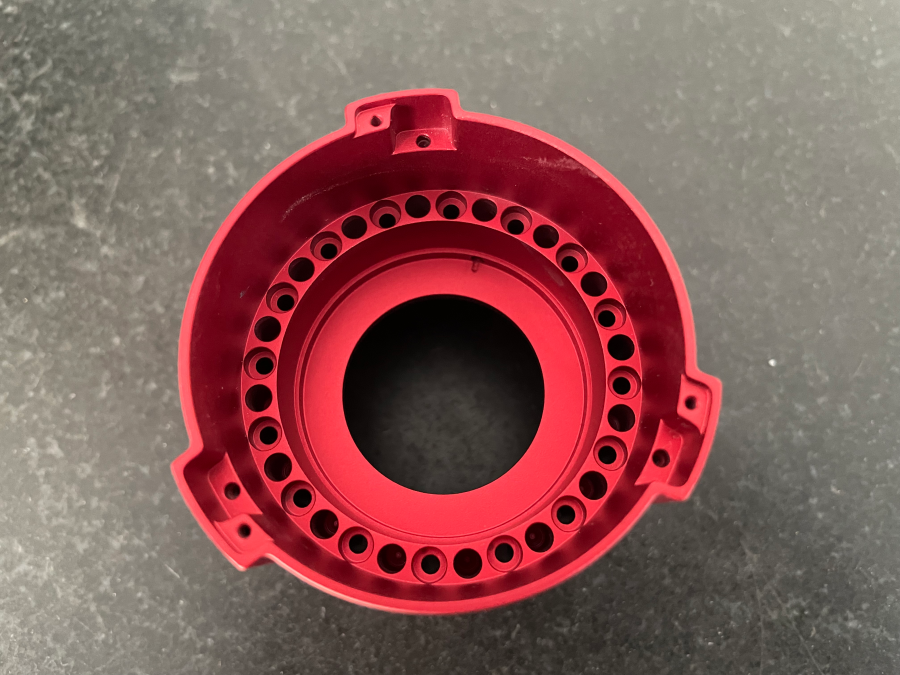

Traditional three-axis CNC machines operate along the X, Y, and Z axes, limiting their ability to machine complex geometries without multiple setups. Five-axis CNC machining adds two rotational axes (typically A and B), enabling the cutting tool to approach the workpiece from any direction in a single operation. This reduces setup times, eliminates human errors, and achieves tolerances as tight as ±0.001mm—a critical requirement for aerospace, medical, and automotive components.

Key Advantages of Five-Axis Machining:

Unmatched Precision: Simultaneous multi-axis movement ensures consistent tool-to-workpiece contact, minimizing deviations.

Complex Geometry Capability: Ideal for parts with undercuts, deep cavities, or organic shapes (e.g., turbine blades, humanoid robot joints).

Reduced Lead Times: Single-setup machining cuts production time by up to 50% compared to multi-stage processes.

Material Efficiency: Optimized tool paths reduce waste, lowering costs for expensive alloys like titanium or Inconel.

GreatLight CNC Machining Factory: A Benchmark in Precision Manufacturing

Founded in 2011 in Dongguan’s Chang’an District—China’s hardware and mold capital—GreatLight Metal Tech Co., LTD. (operating as GreatLight CNC Machining Factory) has evolved from a local workshop into a global precision manufacturing partner. With 127 pieces of advanced equipment, including 12 high-precision five-axis CNC centers, the factory combines technical prowess with a full-process chain covering prototyping, machining, die casting, 3D printing, and post-processing.

Core Competencies:

Ultra-High Precision:

Tolerances down to ±0.001mm (0.00004 inches), verified by in-house CMM (Coordinate Measuring Machine) and laser scanning.

Maximum part size: 4,000mm, catering to large-scale aerospace or industrial components.

Certified Quality Assurance:

ISO 9001:2015 for general quality management.

ISO 13485 for medical hardware production.

IATF 16949 for automotive and engine component manufacturing, ensuring compliance with global automotive supply chain standards.

Material Versatility:

Metals: Aluminum, stainless steel, titanium, magnesium, brass, and superalloys like Inconel and Hastelloy.

Plastics: ABS, PC, PEEK, Nylon, and ULTEM for prototyping or end-use parts.

Rapid Turnaround:

Prototypes delivered in 3–7 days, with express services for urgent projects.

Scalable production from 1 to 100,000+ parts without compromising quality.

Addressing Client Pain Points: How GreatLight Delivers Value

Pain Point 1: The “Precision Black Hole” – Inconsistent Quality in Mass Production

Issue: Suppliers often promise extreme precision but fail to deliver due to outdated equipment or unstable processes.

GreatLight’s Solution:

100% in-process inspection using real-time monitoring systems.

Free rework or full refund for quality issues, backed by ISO-certified workflows.

Pain Point 2: High Costs for Complex Parts

Issue: Five-axis machining is perceived as expensive, pushing clients toward less precise alternatives.

GreatLight’s Solution:

Optimized tool paths reduce machining time and material waste.

Volume discounts for large-scale orders, with transparent pricing models.

Pain Point 3: Slow Prototyping Cycles

Issue: Delays in prototyping can bottleneck product development timelines.

GreatLight’s Solution:

3-axis, 4-axis, and 5-axis CNC machines work in parallel to prioritize urgent projects.

3D printing integration for rapid conceptual validation before machining.

Industry-Specific Expertise: Case Studies

1. Aerospace: Lightweight Turbine Components

Challenge: A client needed titanium turbine blades with 0.002mm surface finish and internal cooling channels.

GreatLight’s Approach:

Used five-axis simultaneous machining to achieve complex geometries in one setup.

Applied EDM (Electrical Discharge Machining) for internal channels, ensuring zero burrs.

Result: 98% reduction in post-machining polishing time.

2. Medical: Custom Orthopedic Implants

Challenge: A medical device firm required biocompatible titanium implants with porous structures for bone integration.

GreatLight’s Approach:

Combined five-axis CNC machining for macro-features with SLM 3D printing for micro-porosity.

Adhered to ISO 13485 standards for cleanroom production and traceability.

Result: FDA approval achieved 30% faster than industry average.

GreatLight vs. Competitors: A Technical Comparison

| Parameter | GreatLight CNC Machining Factory | Competitor A (Large-Scale Manufacturer) | Competitor B (Niche 5-Axis Shop) |

|---|---|---|---|

| Max Tolerance | ±0.001mm | ±0.005mm | ±0.002mm |

| Max Part Size | 4,000mm | 2,500mm | 1,500mm |

| ISO Certifications | 9001, 13485, IATF 16949 | 9001 only | 9001, IATF 16949 |

| Material Options | 50+ metals/plastics | 30+ metals/plastics | 20+ metals |

| Post-Processing | Anodizing, plating, painting, grinding | Basic deburring only | Anodizing, grinding |

| Lead Time (Prototypes) | 3–7 days | 10–14 days | 5–10 days |

Conclusion: Why GreatLight Is the Partner of Choice

In the realm of precision parts manufacturing, GreatLight CNC Machining Factory bridges the gap between ambitious designs and flawless execution. Its five-axis CNC expertise, ISO-certified quality systems, and full-process capabilities make it the ideal choice for industries where failure is not an option—aerospace, medical, automotive, and beyond. By choosing GreatLight, clients gain more than a supplier; they secure a collaborative partner dedicated to pushing the boundaries of what’s possible in precision manufacturing.

For high-end hardware innovation, the path to success starts with the right manufacturing partner. Explore GreatLight’s five-axis CNC machining services and discover how precision, speed, and reliability can coexist.

Frequently Asked Questions (FAQs)

Q1: What industries does GreatLight serve?

GreatLight specializes in aerospace, medical, automotive, robotics, and industrial automation, with capabilities tailored to high-precision, high-stakes applications.

Q2: How does GreatLight ensure data security for IP-sensitive projects?

The factory complies with ISO 27001 standards, implementing encrypted file transfers, restricted access protocols, and non-disclosure agreements (NDAs) for all projects.

Q3: Can GreatLight handle large-scale production runs?

Yes. With three wholly-owned plants and 127 machines, GreatLight scales seamlessly from prototypes to 100,000+ parts, maintaining consistent quality through automated inspection systems.

Q4: What post-processing services are included?

GreatLight offers one-stop finishing, including anodizing, electroplating, powder coating, bead blasting, and CNC grinding, eliminating the need for external vendors.

Q5: How does GreatLight compare to overseas manufacturers?

Unlike many overseas suppliers, GreatLight combines local proximity (Dongguan, China) with global standards, offering faster communication, shorter lead times, and easier quality audits. Its ISO 13485 and IATF 16949 certifications further distinguish it from non-certified competitors.

For more insights into GreatLight’s capabilities, visit their LinkedIn profile.