01Introduction

With the rapid development of intelligent manufacturing, sophisticated and complex mechatronic drive control systems are required in the fields of high-end healthcare, mobile solutions, aerospace, industrial automation 4.0, the Internet of Things and artificial intelligence, which places increasing demands on transmission gears. With increasing precision and miniaturization, the demand for precision small parts transmission parts is also increasing. This article discusses and studies the cutting processing technology of high-precision transmission ultra-thin small module gears.

02 Gear operating environment

High-precision fine gears will need to be welded to an output gear, as shown in Figure 1. The rotation speed is 5000 rpm, the output torque is 6 cNm, the environment temperature is working is 50℃~60℃ and the lifespan is about 4000 hours after 100 million times. The selection and heat treatment of gear materials are very critical. After comparing the characteristics of different stainless steel materials, the 2Cr13 material was finally selected. The heat treatment system is quenching 1040℃/40 min + tempering 580℃~600℃/60 min. not only guarantee the hardness of the material, but also can reduce the hardness fluctuation range.

Figure 1 Application of thin gears with small modules

03 Gear Settings

According to technical index requirements, environmental requirements, service life requirements, etc. parts, the gear parameters are determined as follows: modulus 0.2mm, pressure angle 20°, number of teeth 80, tooth thickness 0.3mm, gear accuracy less than GB. /T level 6, gear flatness requirement 0.005mm.

04Gear cutting tools

High-precision fine and small module gear processing requires the three-in-one concentricity of the main transmission system of the hobbing machine, the hob spindle and the product installation device to ensure gear machining precision requirements. In order to meet the precision level requirements of gear machining, the machine main shaft transmission should adopt “zero transmission” technology, product disassembly and assembly methods, elimination of chips during processing, and the control system should protect personnel as much as possible. simplify debugging and verification and reduce non-production costs in production. At the same time, we selected imported special equipment WAHLI W1000micro for processing small module gears from Wari, Switzerland (for consultation on small module gear cutting machine in Wari, please call: 13522079385). The loading system supplied with the W1000micro equipment is used as a positioning device.

For the design of small module cutting tools with hardness of 38~42HRC, the axial section should be transformed into rack-shaped teeth, which can not only guarantee the cutting precision, but also improve the working life. tool life. uses MIKRON’s 0.2mm modular custom knives.

For gears with a modulus of 0.2mm, the GTR-4PC double-sided mesh measuring instrument from Osaka, Japan is generally used internationally. Small and medium module gear precision detection can quickly measure the complete gear deviation with relatively high precision. It can be used to detect the radial overall deviation and radial runout of the gear. gearing and backlash etc. The special software designed by this instrument can correct the radial runout error of the standard gear, reduce the impact of the radial runout error of the standard gear on the measurement results, and can automatically reset the center distance to zero, so that the measurement accuracy can be further improved.

05 Process Search

Conventional milling processing can generally produce gears with level 8 precision; the above precision milling machine imported from Switzerland (telephone: 13522079385) and precision milling processing imported from Germany can produce 4-5 level precision, meeting the precision of fine and small module gears . . GB/T Level 6 requirements. Now we will conduct research and experiments on gear cutting technology.

Process 1: Raw materials – roughing – vacuum bright heat treatment – finishing – slicing – grinding – gear hobbing – inspection.

Second process: raw materials – rough cutting – vacuum bright heat treatment – finishing – trimming – slicing – grinding – inspection.

tap after slicing

(1) One-piece gear cutting.

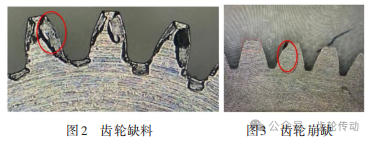

One-piece gear hobbing first requires a custom device to fully press the gear part. Since the hardness of the material is 38-42 HRC, vibration occurs during the gear hobbing process, causing damage to the gear. Once the clamp is released, the gear part will deform and cannot. meet GB/T 6 precision level. The required flatness is 0.005mm; The faulty images are shown in Figure 2 and Figure 3.

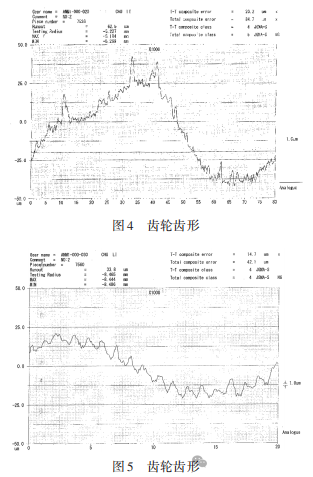

The precision level of the gear is GB/T 8~9 precision. The tooth shape of the test gear is shown in Figures 4 and 5.

(2) Multi-piece cutting.

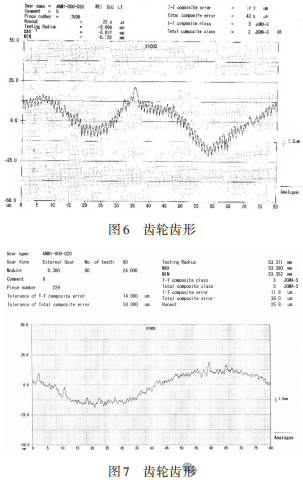

Multi-piece gear cutting involves layering and combining single parts for an overall gear cut. This requires high flatness of the one-piece parts, otherwise there will easily be gaps between the parts during the hobbing process. down. A toothed part, and the burrs are difficult to clean. The types and images of defects are the same as those of one-piece gear cutting. The precision level of the gear is GB/T 7~8, as shown in Figures 6 and 7.

To sum up, whether the material of the hobbing process after slicing is a single piece of gear hobbing or multiple pieces of gear hobbing, it cannot meet the requirements of gear parameters.

Slicing after cooking

Integral gear hobbing is to first machine a small modulus fine gear sleeve, as shown in Figure 8. In this way, the rigidity of the product is sufficient, and the tightening and positioning of the fixture can easily guarantee the concentricity requirement of 0.005 mm. . Using the overall gear hobbing process requires the addition of a slow wire cutting and grinding process to ensure that the thickness of the single gear is 0.3mm and the flatness is 0.005 mm, as shown in Figure 9.

During the slow wire cutting process, it is necessary to pay attention to the zero position for too long, which will cause electrical corrosion of the gear part, resulting in defects such as missing and dented gear front ends . The faulty image is shown in the figure. 10.

Figure 10 Image of slow and poor wire walking process

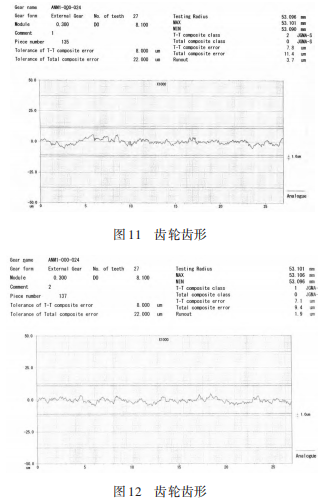

The precision level of the gear is GB/T 5~6, which fully meets the precision level requirements of the gear, as shown in Figures 11 and 12.

06 Summary

For high precision fine and small module gear cutting, the recommended processing technology is: raw material – roughing – vacuum bright heat treatment – finishing – hobbing – slicing – grinding – inspection. Using WAHLI W1000micro equipment and MIKRON tools to cut fine and small module gears can produce gears with GB/T level 6 gear accuracy very efficiently and stably in batches.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.