As an ultra-short pulse laser source, femtosecond laser has shown great potential in the field of ultra-precision micro-machining in recent years due to its unique ultra-fast time scale (femtosecond level, 1 femtosecond = 10-15 seconds) and its high peak. power. By combining with femtosecond lasers, it is possible to achieve ultra-precise machining of various materials, from metals to semiconductors, achieving nanometer precision and extremely high surface quality.

Advantages of femtosecond laser micromachining

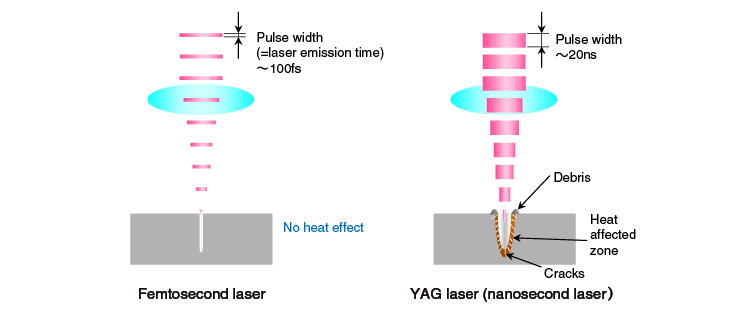

1. Thanks to the extremely short energy deposition time, the treatment can be carried out without thermal effects.

Since the pulse duration of femtosecond lasers is approximately 100 fs (1fs = 10-15 s), the laser exposure is completed before heat is transferred to the material. As a result, the material can be processed without causing thermal cracks or spalls (substances melted or vaporized by the laser and re-adhering to the surface of the material). In comparison, the use of YAG lasers has longer pulse durations of around 20 ns (1 ns = 10-9 s), which can lead to cracking in the heat affected zone and around the heat treated area. laser. The difference in pulse timing between these two lasers can be better understood by the propagation distance; a 100 fs pulse and a 20 ns pulse will move 30 μm and 6 m, respectively;

Source: Orbray official website

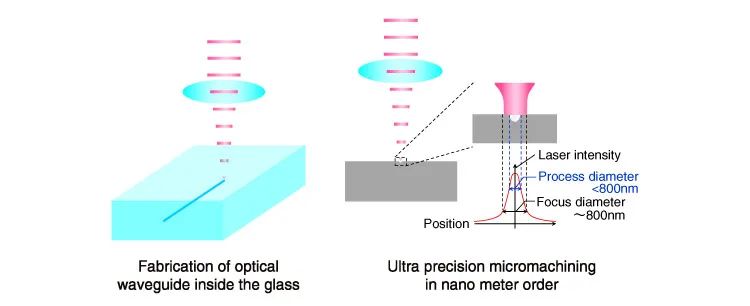

2. By using a focusing lens to achieve high laser intensity, microstructures can be formed only in the focusing area.

The wavelength of the femtosecond laser is 800 nm, which is not powerful enough to cause adsorption on transparent materials such as sapphire and quartz glass. However, since high laser intensity exceeding 10 TW/cm2 can be achieved at the focus, microstructures can only be formed in the focus area. By exploiting this capability, optical waveguides and microfluidic devices can be created inside glass. Since all materials (metals, semiconductors, glasses, ceramics) can be processed with femtosecond lasers, they can be used for drilling, cutting and making grooves. Although the minimum diameter of a focused laser is usually the same as its wavelength, by using the high intensity part of the laser it is possible to create nanostructures smaller than the laser wavelength. Defects (chips and dents) in semiconductor photomasks can also be repaired.

Source: Orbray official website

Application of femtosecond laser in diamond processing

Processing of micro-nanostructures

Application: Femtosecond lasers can be used to process micro-nano structures on the surface and inside of diamond, such as microlens arrays, photonic crystals, microfluidic channels, etc.

Technical principle: using the ultra-short pulses and high peak power of femtosecond lasers to achieve high-precision removal and modification of diamond materials through the multi-photon absorption effect.

Precision drilling and cutting

Application: Femtosecond laser can be used for precision diamond drilling and cutting, achieving aperture and cutting precision in the micron or even nanometer range.

Technical principle: By controlling the focus and scanning path of the laser beam, precise removal of diamond material is achieved to avoid thermal effects and cracking.

Surface modification and polishing

Application: Femtosecond laser can be used to modify the surface of diamond, such as improving the surface roughness and obtaining a smooth surface, etc.

Technical principle: Use the low thermal impact characteristics of femtosecond lasers and control the laser energy density and pulse repetition frequency to achieve fine polishing and modification of the diamond surface.

Three-dimensional processing and manufacturing of complex structures

Application: Femtosecond laser can realize three-dimensional processing of diamond materials and manufacture complex three-dimensional structures, such as three-dimensional photonic crystals, microelectromechanical systems (MEMS), etc.

Technical principle: By controlling the focusing position and scanning path of the laser beam, three-dimensional removal and modification of diamond materials is achieved.

Advice material: 15910974236

Finally

The application of femtosecond lasers in the processing of diamond materials demonstrates its enormous potential in the field of ultra-precision micro-nano processing. Using the characteristics of femtosecond lasers such as ultra-short pulses, high peak power and low thermal impact, it is possible to achieve high-precision micro-nano processing of diamond materials. In the future, with the continuous advancement of technology, femtosecond lasers will play an increasingly important role in semiconductor, optics, biomedicine, aerospace and other fields. areas, particularly in the application of diamond materials, thus offering broader development prospects.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.