01

Features of ultrafast laser technology

In industry, lasers can be divided into four types according to the light emission time: continuous wave, quasi-continuous wave, short pulse and ultra-short pulse. “Ultrafast laser” refers to a pulse laser whose output laser pulse width is 10-12s, that is, the picosecond level, or less than the picosecond level. Lasers with pulse widths between a few tens and 1 nanosecond are generally called sub-nanosecond lasers. The ultrashort pulses generated by ultrafast lasers interact with the material for a very short duration and can effectively deliver laser energy into the material before thermal diffusion occurs. Compared with long pulse lasers, ultrashort pulse lasers are unique in terms of multiphoton ionization and energy transfer from electrons to the crystal lattice, and the thermal damage caused by processing is negligible, so they are also called cold processing. Ultrafast laser is one of the important development directions in the laser field. As an emerging technical means, it has significant advantages in precision micromachining.

Figure 1. Principle of ultrafast laser-material interaction of different materials

02

Ultra-fast laser additive manufacturing

Additive manufacturing (AM) has become a key area for the 3D manufacturing of objects with arbitrary geometries. The use of ultrafast lasers for additive manufacturing opens the possibility of next-generation manufacturing technologies for difficult-to-process materials, transparent materials, and micro- and nanofabrication.

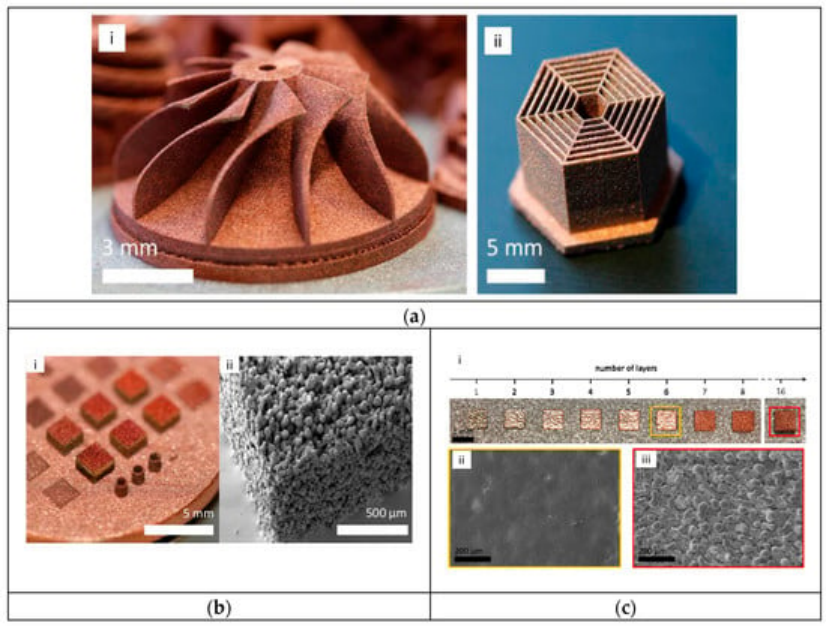

Figure 2. Fabrication of copper parts by selective laser melting (SLM) with ultrafast lasers

Two-photon polymerization (2PP) is a micro-nano 3D printing technology that selectively solidifies photoresist using a femtosecond pulse laser. It is similar to photopolymerization rapid prototyping, but 2PP 3D printing technology can produce complex structures with resolutions in the hundreds. of nanometers. The three-dimensional (3D) structure is hundreds of times more precise than traditional photopolymerization molding technology. Austrian scholar Aleksandr Ovsianikov used two-photon polymerization technology to design and synthesize six-functional urethane-based telechelic polycaprolactone (PCL) with three acrylate groups on each end group. This type of biodegradable material, capable of meeting resolution requirements, can be used in the manufacturing of biomedical micro-scaffolds and has significant application potential in the field of tissue engineering.

Figure 3. (a) Simplified schematic of the 2PP process (b, c) SEM images based on UPCL-2 microstructure (d, e) SEM images based on UPCL-6 microstructure.

Counseling Material Telephone Number: 15910974236

03

Ultra-fast laser cutting

The wall of the cardiac stent tube is extremely thin, and laser processing is usually used instead of conventional mechanical cutting. However, using ordinary lasers for ablation and fusion treatment presents a series of problems such as numerous burrs, inconsistent groove widths, large surface ablation, and uneven rib widths. When using a high-speed laser to cut vascular stents, not only a high-quality cutting plane can be obtained, but also a small heat-affected zone on the cutting surface, precise cutting seams and a smooth surface can be guaranteed.

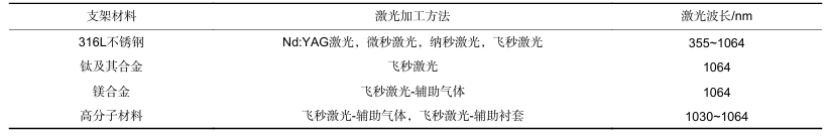

Table 1. Vascular stent processing materials and laser methods

At the same time, given the problems encountered with traditional metal stents, researchers began to focus on the development of biodegradable polymer vascular stents. Among them, high molecular weight polymers are commonly used materials for non-metallic degradable stents. In order to solve the problem of the sensitivity of materials to thermal effects, Stolberg et al. used a femtosecond laser combined with multiple ablation processes to cut and prepare square PLLA sheets, so that the heat-affected zone could be well controlled.

Figure 4. Femtosecond laser cutting of polymer materials, including poly-L-lactic acid (PLLA)

04

Ultra-fast laser microwelding

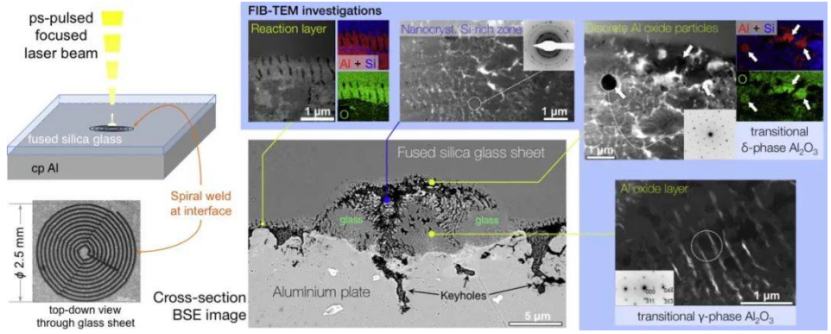

For transparent solid media such as glass, ultrashort pulse laser propagation in the media will cause nonlinear absorption, melting damage, plasma formation, ablation, optical filament propagation and other phenomena. Ultrafast laser microwelding glass technology is based on the nonlinear absorption mechanism of ultrafast laser energy, which allows different materials to be plasmaized in the microscale range of the bonding interface, and then rebuild them to get a connection. Octav P. Ciuca and others used the picosecond laser to weld aluminum and glass, achieving revolutionary technology in welding between metal and glass.

Figure 5. Picosecond laser welding of metal and glass

05

Ultrafast laser preparation of surface microstructures

Although traditional surface treatment technology can improve the biological activity of material surfaces, its process is complex and the surface properties of treated materials are unstable. Laser micromachining technology is simple and can produce microscopic three-dimensional structures on the surface of implants. The surface properties of the modified implants are stable and have little impact on the matrix. Wang Rui et al. studied the role of ultrafast laser processing technology in surface modification of Ti6Al4V alloy, using a femtosecond laser to process the surface microstructure of polished titanium alloy. It was found that the biocompatibility of the titanium alloy surface modified by laser treatment was improved, which promoted cell proliferation and differentiation and promoted the osseointegration ability of implants.

Figure 6. Femtosecond laser fabrication of surface micro-nanostructures

Consult ultrafast laser equipment: 15910974236

06

To summarize

At present, as the minimum feature size that can be obtained by micromachining technology continues to decrease, the continuous improvement of processing precision and quality has always been a problem to overcome. The excellent performance of ultra-fast laser processing technology in the field of micromachining has attracted more and more attention from industry and academics. The rapid development of the manufacturing industry and the search for more efficient materials will inevitably lead to equally rapid developments in processing methods.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.