1. Introduction:

CNC grinding machines combine the advantages of mechanical technology and information technology, so they are very suitable for processing high-precision parts. There are some common problems when using CNC grinders for grinding processing, which affect the processing effect of the workpiece surface.

had some negative impact. For example, the finish of the part is insufficient, there are errors in the accuracy of the part, and cracks appear on the surface due to burns, etc. In this regard, manufacturing enterprises should adopt reasonable countermeasures, such as error compensation processing, grinding parameter control, etc., to effectively solve the above grinding processing problems and ensure quality and the performance of the treated parts. This article starts from the problems of grinding processing and discusses countermeasures to common problems for reference.

2. Common problems when grinding with CNC grinders:

2.1 Scratches appear on the surface of the part:

When using a CNC grinder for grinding, scratches may appear on the surface of the workpiece. The main reason is that the wheel used for grinding interacts with the surface of the workpiece when operating at high speed, causing sand grains on the surface. The grinding wheel falls, and the fallen sand particles are stuck on the grinding surface or mixed with the grinding liquid, resulting in scratches caused by extrusion between the sand particles and the workpiece surface during processing. There are three main factors for this situation: the grinding wheel, the grinding fluid and the grinding parameters.

First of all, the millstone factor. Since the grinding wheel is self-sharpening, the loss of sand particles is completely inevitable. If the hardness of the grinding wheel is low, the sand grains on the surface of the grinding wheel will fall off the grinding wheel more easily, and the hardness of the sand grains should be higher than the hardness of the workpiece. Stuck on the processing surface, it may cause scratches on the workpiece. Second, the grinding fluid factors. In the grinding process, grinding fluid is a very important auxiliary material, which can quickly and effectively play lubricating, cleaning and other functions during the grinding process. Grinding fluid is usually sprayed between the grinding wheel and the workpiece through a nozzle. So, once the sand particles falling from the grinding wheel are mixed with the grinding fluid, it may cause scratches on the workpiece, due to factors related to the grinding parameters. With the continuous improvement of workpiece processing requirements, if the grinding parameters are improperly adjusted, it may damage the surface finish of the workpiece. For example, increasing the grinding depth and rotation speed of the workpiece will increase the grinding force, resulting in serious plastic deformation of the workpiece, and the surface finish will not meet the processing requirements. In addition, if the wear of the grinding wheel is large and the dressing is not carried out in time, it will also affect the surface of the workpiece.

2.2 Workpiece grinding precision deviation:

As an important equipment for workpiece processing, CNC grinding machines must ensure the accuracy of workpieces and solve error problems through grinding, because the requirements for workpiece processing accuracy are increasing day by day. From the perspective of the source of precision deviation, the workpiece error is mainly caused by geometric error (motion error) and thermal error. Geometric errors are usually motion path errors during the grinding process during grinder manufacturing. The components are constantly moving and moving, causing the spatial position to not match the reference value, thereby causing errors. Thermal error is due to the thermal deformation of the equipment during grinding processing, resulting in errors in the positional accuracy and straightness of the equipment, which ultimately makes the actual grinding effect somewhat different from the one expected. Compared with other processing methods, the grinding process involves a large amount of grinding heat, so the probability of thermal errors is high. Added to this are also the effects of external factors, notably temperature factors. Proper working temperature can maximize machining accuracy. Too high or too low temperature will affect it, preventing the part from meeting the grinding dimensional tolerance requirements. Specifically, if the temperature is too high, the cooling effect of grinding will inevitably be affected, and the probability of thermal deformation will increase. If the temperature is too low, the grinding heat and measuring tools will be affected to a certain extent, as well as the materials; such as grinding fluid must be heated. The processing is not only inaccurate, but also affects the effectiveness of the treatment.

2.3 Grinding burns and cracks:

When using a CNC grinder to grind parts, it is common for burns or cracks to occur on the surface of the part. However, the strength, hardness and other properties of the part burned on the surface will be reduced, thereby affecting the service life. of the workpiece. The principle of grinding burn is that the grinding zone will generate an instantaneous high temperature once the high temperature reaches the phase change temperature range, this will cause changes in the surface of the workpiece and reduce the resistance and hardness of the metal. At the same time, CNC grinders use coolant to dissipate heat, which can cause the austenite remaining on the workpiece surface to form secondary quenching martensite. This part cannot be loaded under the action of tensile stress on the surface and internal layers, and. cracks will occur.

The influencing factors that lead to the occurrence of grinding burns can be roughly divided into two categories, namely material factors and process operation factors. The core of the material factors lies in the retained austenite, which is the key to the formation of martensite. When the retained austenite of the workpiece is subjected to the thermal energy and pressure generated during grinding, it can transform, causing cracks. The appearance of austenite is linked to the carbon concentration of the carburizing layer. When the carbon concentration is too high, the instantaneous high temperature of grinding will cause tempering on the surface, thereby producing retained austenite. Therefore, these two factors must be reasonably controlled. The carbon concentration must be maintained between 0.75% and 0.95%, and the austenite retained must avoid exceeding 30%. The process operation factors are more complex, including grinding parameter issues, grinding wheel problems, cooling methods, etc. In terms of grinding parameters, grinding allowance, grinding quantity, workpiece speed, grinding wheel parameters, and backlash can all cause burns. When it comes to grinding wheels, high heat generation, poor heat dissipation and insufficient chip removal are the main factors that cause burn-in problems. Therefore, attention should be paid to the selection of grinding wheel material, grain size, hardness and diameter. necessary, special treatment of the grinding wheel is required to improve the cooling performance and chip evacuation capabilities. In terms of cooling methods, grinding fluid and coolant are key factors that cause parts to burn.

3. Solutions to common grinding problems with CNC grinders:

3.1 Reasonably adjust the grinding process to reduce scratches on the workpiece surface:

In order to reduce scratches on the workpiece surface and improve the surface finish, it is necessary to control the grinding wheel, grinding fluid and grinding parameters. When selecting grinding wheels, the required grinding wheels should be selected reasonably according to the different materials of the workpiece, and the hardness and toughness characteristics of the abrasive should be fully considered to improve the smoothness of the surface. of the room. Generally, the higher the hardness, the more difficult it is for the sand to fall; the softer it is, the more easily it falls. When grinding higher hardness materials, you can choose a lower hardness wheel to allow the abrasive to fall off during grinding, exposing new abrasive to maintain the sharpness of the wheel. In terms of grinding fluid, in order to avoid abrasives being mixed with the grinding fluid, the position, flow rate and injection pressure of the grinding fluid nozzle should be reasonably adjusted to maintain the grinding fluid in the pure grindstone and room. In terms of grinding parameters, on the one hand, the process parameters, that is, the grinding quantity, should be set reasonably to ensure that the problem of plastic deformation of the workpiece during processing is within ‘otherwise within a reasonable range; The wheel must be dressed to avoid dullness. The grinding wheel is sharpened to improve grinding efficiency and surface finish. When dressing, it is also necessary to control the dressing amount and dressing speed, and use a small amount of multiple and rapid dressing to ensure the working state of the grinding wheel. Workpiece processing is divided into coarse grinding and fine grinding. Before fine grinding, the wheel should be dressed to reduce scratches on the workpiece and ensure a smooth surface.

3.2 Perform precision movement control to improve the grinding precision of the wheel:

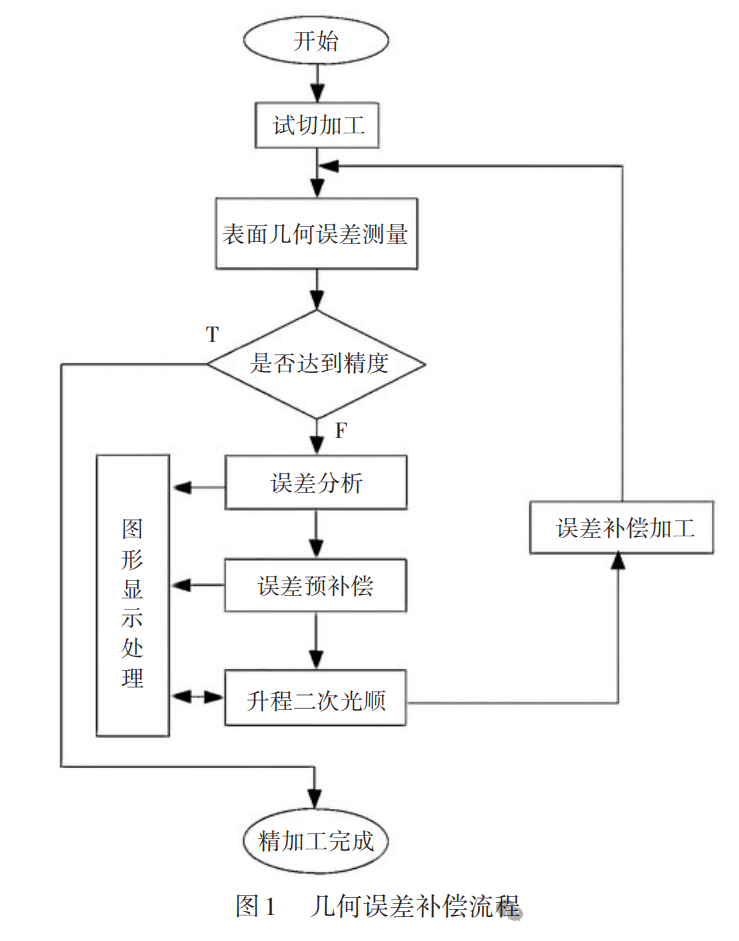

In order to improve the precision of workpiece grinding, it is necessary to control geometric errors and thermal errors. First, geometric error control. On the one hand, in order to ensure the accuracy of the movement trajectory of the grinder and reduce the spatial error caused by movement, the control instruction algorithm can be used to constrain the operational links. During the grinding process, the operating trajectory of the grinding wheel and other structures should be the same as the theoretically planned position and trajectory. This is the prerequisite for precise control of movement. Based on this, the relative motion constraint equation is constructed to calculate the. Corresponding CNC drive instruction value to control and constrain the working process of the grinding machine. On the other hand, the geometric error can be measured through error pre-compensation, and the part can be processed with error compensation based on the compensation value (see Figure 1).

Second, thermal error control. There are three general thermal error control methods: one is thermal compensation, which means monitoring the temperature of the grinder through detection equipment and calculating the thermal error compensation according to the temperature value in time real, then correct it to achieve the compensation effect. ; the other is to improve the structure of the crusher, select stiffer and stronger materials to change the structure of key parts. to reduce thermal distortion problems during processing and reduce errors; or use thermal stress relief devices to reduce the impact of thermal deformation on the work process; third, adopt spindle cooling measures, including installing cooling devices, replacing materials with low thermal expansion, etc. , eliminates excess heat in the spindle and reduces thermal deformation of the spindle. Third, in terms of working temperature control, the ventilation system should be used to control the ambient temperature between 20°C and 25°C, which can minimize the impact of temperature on the accuracy error of grinding.

3.3 Reasonably control combustion factors and optimize grinding process operations:

Many factors affect part burning. During grinding operations, you can start from the following three aspects: reasonable control of grinding parameters, selection of suitable grinding wheels and optimization of cooling methods.

Firstly, the basic principle of grinding parameter control lies in adequacy, that is, the rational selection of the parameters required for grinding and making the necessary adjustments. If burns occur when the grinding amount is small, the longitudinal feed speed should be increased; on the contrary, if burns occur on the workpiece when the grinding quantity is large, the feed should be reduced and the grinding frequency should be increased; . It is necessary to reasonably judge the speed of the workpiece to maintain the appropriate speed. It is necessary to control the balance of the grinding wheel and resolve problems such as excessive spindle vibration and excessive backlash.

Secondly, the key to choosing grinding wheels is to reduce heat generation, improve heat dissipation and completely eliminate chips. Based on this standard, the abrasive of the grinding wheel must match the workpiece; the particle size of the grinding wheel should be selected to meet the processing requirements in terms of grinding wheel hardness, try to choose a softer grinding wheel in the grinding wheel; structure In terms of grinding wheel diameter, a grinding wheel with a smaller diameter should be chosen to reduce the grinding area. In addition, the grinding wheel can also be treated appropriately, for example grooved on the use surface to improve heat dissipation and chip removal. The grinding wheel should be repaired in time, including passivation problems, balance problems, etc.

Third, when choosing grinding fluid, it is best to use oily products and use wet grinding fluid.

The grinding method ensures sufficient supply of grinding fluid and high pressure to promote cooling and chip removal. When choosing coolant, choose pure coolant with appropriate viscosity and keep the temperature low to achieve the cooling effect.

4. Conclusion:

In summary, with the development of the social economy, the requirements for quality and precision in the processing of manufacturing parts are increasingly higher. When processing parts, using CNC grinders for grinding is a common method of surface treatment of parts. When grinding parts, problems such as surface scratches, precision errors and surface burns often occur. Relevant personnel should conduct in-depth analysis of the above problems, evaluate the various causes of the problems, and take targeted measures to remedy them to ensure. that The processing quality of the part meets the requirements.

Data source for this article: Mold Manufacturing Issue 6, 2024, contributed by Beijing Haibao Precision CNC Machinery Co., Ltd. Author: Zheng Yucai

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.