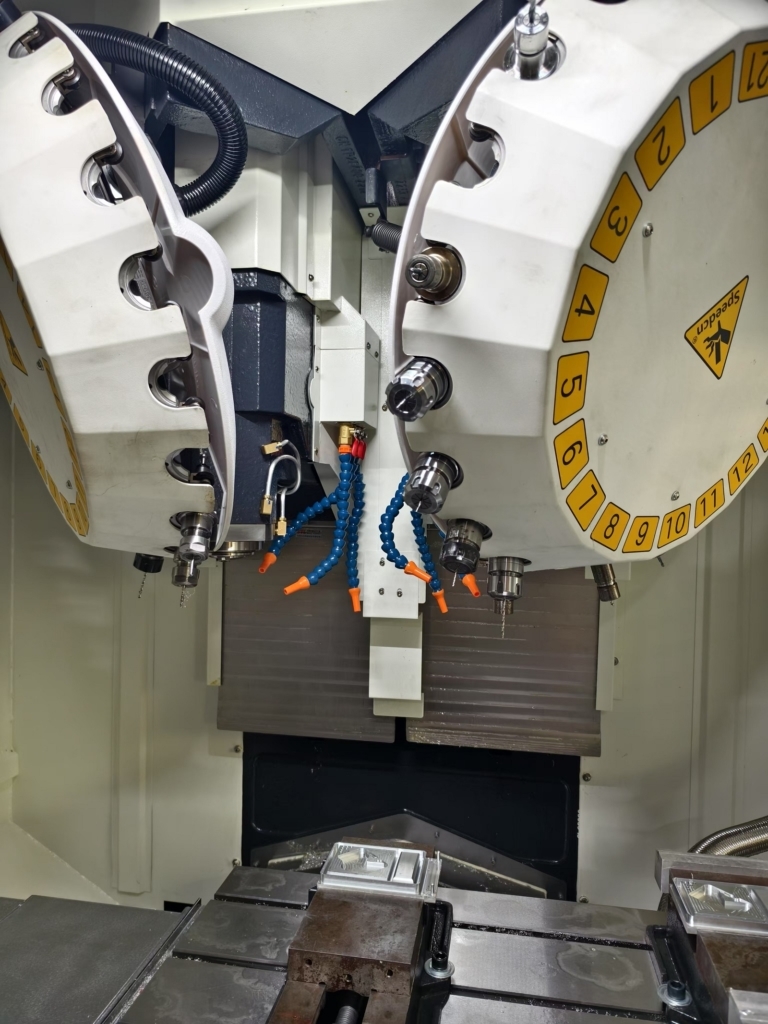

How to troubleshoot the CNC system of a twin-spindle machining center?

Double pinmachining centerTroubleshooting CNC system involves many aspects, including spindle system, power transmission system, control system, etc. Here are some common CNC system faults and their troubleshooting methods:

1. Spindle system faults and troubleshooting methods

The spindle does not work

Fault phenomenon: the spindle cannot start or work.

Possible reasons:

Line connection error.

The system has no relative spindle control signal output.

The power supply line and control signal output line are short-circuited or the components are damaged.

Mechanical transmission failure, such as belt drive failure.

Troubleshooting :

Carefully refer to the circuit connection guide to ensure correct wiring.

Use a multimeter to test the signal output end. If there is no spindle control signal output, the affected IC components should be replaced or sent to the factory for maintenance.

Check the power supply circuit and control signal output circuit, repair short circuits or damaged components, and ensure that the contacts are in good contact.

Check if the spindle belt drive is broken. If it is broken, replace it.

The spindle heats up and the rotation precision decreases

Fault phenomenon: The spindle temperature increases and the rotation precision decreases.

Possible reasons:

The spindle bearing is poorly lubricated.

The locating surface of the inner cone hole of the pin is bruised.

The bearing clearance becomes greater.

Troubleshooting :

Replace the spindle bearing grease to ensure proper lubrication.

Grind the locating surface of the inner taper hole of the spindle to ensure that the contact area between the tool holder and the taper centering hole of the spindle meets the requirements.

Adjust the bearing clearance to the specified range.

2. Power transmission system faults and troubleshooting methods

interruption of movement

Fault phenomenon: the movement of a certain axis (such as the Y axis) is interrupted.

Possible reasons:

The circuit breaker has tripped.

The screw nut is stuck.

Troubleshooting :

Check and reset the circuit breaker.

Remove the screw-nut pair, clean it and adjust the preload force.

Check and adjust the sliding guide rail and insertion clearance.

Poor positioning accuracy

Fault phenomenon: the roundness error is out of tolerance when processing the connection of the X and Y axes.

Possible reasons:

Positioning accuracy is poor.

The position compensation settings change.

Troubleshooting :

Call up the position compensation parameters of the CNC system for inspection and adjustment.

Check and adjust the axial play and clearance of each axle.

3. Control system faults and troubleshooting methods

The system is not responding

Fault phenomenon: The CNC system cannot start or respond to operation instructions.

Possible reasons:

Power outage.

System software failure.

Hardware failure.

Troubleshooting :

Check if the power supply is normal.

Restart the system or reinstall the system software.

Check hardware connections and components for damage and replace if necessary.

Signal transmission failure

Symptom: The system cannot receive or send signals correctly.

Possible reasons:

Bad line connection.

Signal interference.

Communication module failure.

Troubleshooting :

Check that wiring connections are secure and not loose or damaged.

Check the sources of signal interference, such as electromagnetic interference, etc., and take corresponding measures to protect them.

Replace the communication module or repair the fault.

4. Other common faults and troubleshooting methods

Failure of rail oil pump and cutting oil pump

Fault phenomenon: The guide rail oil pump or cutting oil pump cannot work properly.

Possible reasons:

Insufficient oil level.

The oil pump is damaged.

The oil line is clogged.

Troubleshooting :

Inject sufficient guide oil or cutting oil.

Replace the damaged oil pump.

Clean the oil line to make sure it is clear and unobstructed.

Steering wheel failure

Fault phenomenon: the steering wheel cannot operate properly or the operation is insensitive.

Possible reasons:

The steering wheel shaft selector has poor contact.

The steering wheel magnification selector switch has poor contact.

The steering wheel pulse generator disk is damaged.

The steering wheel connection wire is broken.

Troubleshooting :

Replace the damaged switch.

Repair or replace damaged pulse generator disk.

Replace broken cables.

In summary, troubleshooting the CNC system of a dual spindle machining center requires in-depth consideration of several aspects, including the spindle system, feed transmission system, control system and others. common faults. When troubleshooting, the fault phenomenon and possible causes should be carefully analyzed and corresponding troubleshooting methods should be adopted. At the same time, daily maintenance and upkeep of equipment should also be strengthened to reduce the probability of breakdown.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.