Inspired by coral, a team of researchers from Swansea UniversityThe bone grafts were 3D printed. Behind this development is actually something new: their research shows that the new material will dissolve naturally in the body once the transplant is complete and could also promote faster healing.

Bone defects caused by fractures, tumors and non-healing injuries are one of the leading causes of disability worldwide. Although bone tissue repairs itself through regeneration, factors such as aging, disease, or the severity of the defect can slow the rate of regeneration. If the defect is large, a scaffold or bone graft will be necessary to complete tissue regeneration.

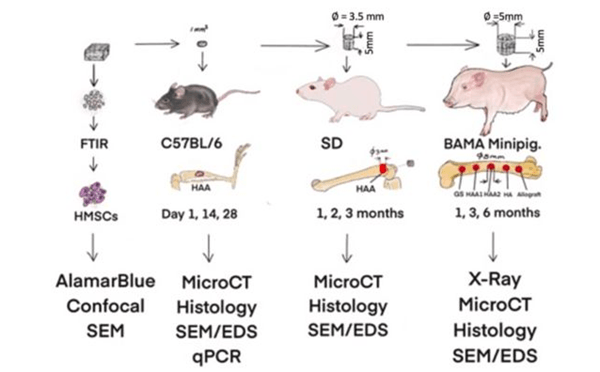

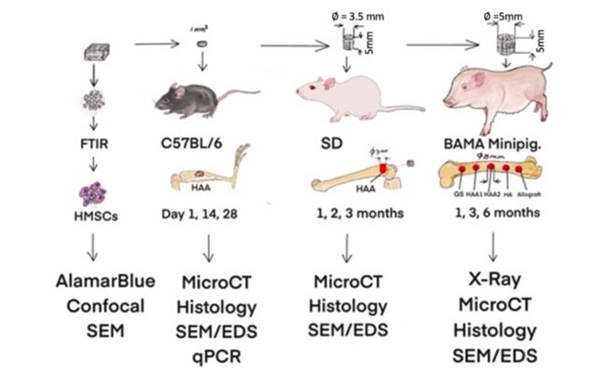

Design of in vitro and in vivo tests (Photo credit: Swansea University)

Traditionally, doctors filled these gaps using the patient’s own bone (autograft) or donor bone (allograft). But limited supplies, infection risks and ethical concerns make these options less attractive. Synthetic bone grafts exist, but they currently cannot compete with the performance of natural bone. They take a long time to dissolve, don’t integrate well, or can cause side effects like inflammation. On the other hand, the material developed by the Swansea team overcomes these difficulties by faithfully imitating natural bone, both in its structure and in its biological behavior.

Why coral?

The researchers are atCorals began to be explored as potential substitutes for bone grafts in the 1970s, and they found that some corals resembled spongy bones. It has the mechanical properties of bone and is biocompatible, osteoconductive and biodegradable. Since then, porous calcium carbonate from natural coral has been recognized as a “clinically useful replacement bone graft material” by the International Journal of Oral Health. Building on this history, the Swansea team developed a new material that mimics the porous structure and chemical composition of coral bone graft substitutes. They 3D print the material using Envisiontec’s Bioplotter 3D printer, or cast it and dry it at room temperature.

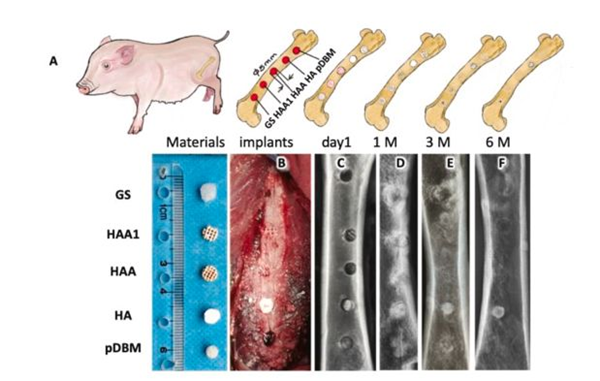

The research team conducted in vivo preclinical trials in rats and dwarf pigs. These tests notably showed that the material completely repaired bone defects in three to six months. Additionally, the material triggered the formation of a new layer of strong, healthy cortical bone within four weeks.

This kind ofRevolutionary results from 3D printed implants

This structure has many advantages. First, it heals quickly, with new bone growing in just two to four weeks. Additionally, the material naturally degrades within six to twelve months following bone regeneration, leaving only so-called healthy bone. Additionally, the material is easier to find than traditional alternatives, natural coral or donor bone. Easy to mass produce.

Dr Zhidao Xia from Swansea University School of Medicine led the research, working with professors from the Departments of Science and Engineering and other external partners.At the end of November, the team announced the results of the patent search.

He concluded:“Our invention bridges the gap between synthetic alternatives and donor bone. We have demonstrated that it is possible to create a safe, effective and scalable material to meet global demand. This could end addiction with regard to donor bone and resolve ethical and procurement issues regarding bone grafting.

Implants made in dwarf pigs (Source: Swansea University)

The Swansea University team now hope to make their technology available to the world by working with businesses and healthcare organizations.3D printed bone grafts can reduce medical costs and improve patients’ quality of life. And the impact doesn’t stop there: research opens new perspectives for the biomedical industry.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.