Precision CNC Machining Services: The Ultimate Guide to High-Accuracy Custom Part Manufacturing

When it comes to producing complex, high-precision metal and plastic components, precision CNC machining services stand out as the gold standard in modern manufacturing. Whether you’re developing next-generation aerospace components, intricate medical devices, or high-performance automotive parts, the ability to transform precise digital designs into tangible, dimensionally accurate parts is non-negotiable. In this in-depth guide, we explore what defines true precision CNC machining, why it matters, and how GreatLight CNC Machining Factory — a top-tier provider headquartered in Dongguan, China — is setting new benchmarks in the field.

What Are Precision CNC Machining Services?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. The term “precision” refers to the ability of the machining process to consistently produce parts within extremely tight tolerances — often as fine as ±0.001mm (0.00004 inches) or better.

Unlike conventional machining, precision CNC machining services leverage multi-axis machines (3-axis, 4-axis, and 5-axis), advanced toolpath strategies, and high-grade materials to achieve:

Exceptional dimensional accuracy

Complex geometries and intricate features

Superior surface finishes

Consistent repeatability across high-volume runs

These capabilities make precision CNC machining indispensable for industries where failure is not an option — such as medical, aerospace, robotics, electronics, and automotive.

Why Precision Matters More Than Ever

In today’s competitive landscape, product performance, safety, and innovation hinge on the reliability of every individual component. Here’s why precision CNC machining services are critical:

1. Tight Tolerances Enable Better Functionality

Components with exacting tolerances fit together perfectly, reducing friction, wear, and the risk of failure. This is especially vital in assemblies where multiple parts must interact seamlessly under stress or motion.

2. Complex Designs Become Feasible

With multi-axis CNC machining, designers are no longer limited by simple geometries. Undercuts, thin walls, internal cavities, and curved surfaces that were once deemed “unmanufacturable” are now entirely achievable.

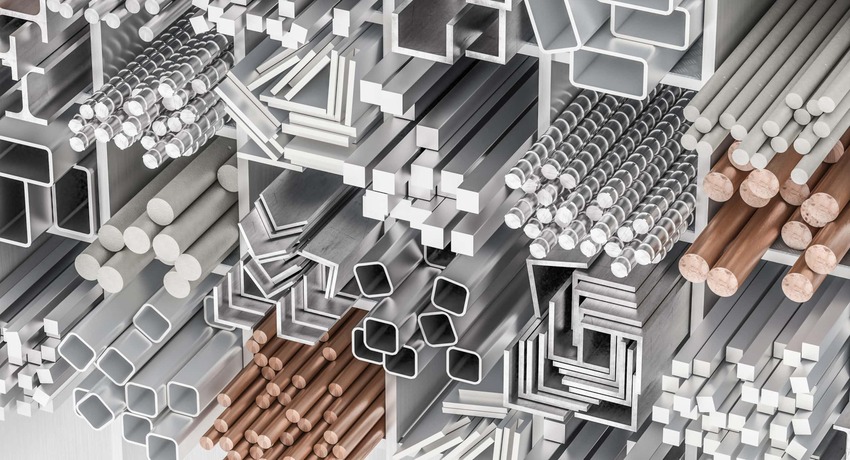

3. Material Versatility Without Compromise

Whether it’s aluminum, titanium, stainless steel, brass, or advanced engineering plastics, precision CNC machining maintains structural integrity and surface quality across a wide spectrum of materials.

4. Faster Time-to-Market

Prototypes and low-volume production runs can be produced in days, not weeks, enabling faster design validation and iteration — a key advantage for R&D teams and startups.

Introducing GreatLight CNC Machining Factory: Your Precision Manufacturing Partner

When searching for a trusted provider of precision CNC machining services, look no further than GreatLight CNC Machining Factory — a professional-grade manufacturer with over a decade of experience delivering unmatched precision and reliability.

🏭 Who Is GreatLight CNC Machining Factory?

Founded in 2011 and headquartered in Chang’an District, Dongguan City — China’s precision hardware and mold capital — GreatLight CNC Machining Factory spans 7,600 square meters and employs 150+ skilled professionals. The company operates a fleet of 127 advanced precision machines, including:

5-axis, 4-axis, and 3-axis CNC machining centers

High-speed CNC milling and turning equipment

Precision grinding and EDM machines

Vacuum casting and sheet metal fabrication units

Industrial-grade 3D metal and plastic printers (SLM, SLA, SLS)

What truly distinguishes GreatLight is its commitment to one-stop, integrated manufacturing — from rapid prototyping and CNC milling to post-processing, surface finishing, and assembly.

Why Choose GreatLight for Precision CNC Machining?

Here’s a breakdown of what makes GreatLight CNC Machining Factory a preferred partner for global innovators and OEMs:

✅ Unrivaled Technical Capabilities

| Feature | Specification |

|---|---|

| Tolerance | Up to ±0.001mm (0.00004 in) |

| Max Part Size | 4000mm (157 inches) |

| Machining Axes | 3-axis, 4-axis, 5-axis CNC |

| Materials Supported | Metals (Aluminum, Titanium, Steel, Inconel) + Engineering Plastics |

| Surface Finishing | Anodizing, polishing, plating, powder coating, brushing |

✅ Advanced Multi-Axis Machining Expertise

GreatLight specializes in 5-axis CNC machining — the pinnacle of precision engineering. Unlike 3-axis machines, 5-axis systems allow simultaneous movement along five different axes, enabling:

The creation of highly complex parts in a single setup

Improved tool access to hard-to-reach features

Enhanced surface quality and fewer errors

Faster production with fewer fixtures

This makes GreatLight the go-to source for humanoid robotics components, aerospace hardware, medical instruments, and high-end automotive parts.

✅ Certified Quality Assurance

GreatLight CNC Machining Factory is ISO 9001:2015 certified, ensuring that every component meets stringent global quality standards. But their commitment doesn’t stop there:

Data Security: Compliant with ISO 27001 for sensitive and intellectual property-driven projects

Medical Device Manufacturing: Certified under ISO 13485

Automotive Industry Standards: Aligned with IATF 16949, the highest standard for engine and vehicle component production

These certifications aren’t just badges — they represent real operational excellence, rigorous process controls, and end-to-end traceability for mission-critical parts.

Addressing the Top Pain Points in CNC Machining

Many businesses struggle with unreliable suppliers who overpromise and underdeliver. Here’s how GreatLight solves the Seven Critical Pain Points in CNC Machining:

| Pain Point | GreatLight’s Solution |

|---|---|

| Inconsistent Precision | State-of-the-art calibration, real-time monitoring, and ISO-certified processes |

| Long Lead Times | Rapid prototyping in days, not weeks |

| Poor Surface Finish | Expert post-processing and finishing services |

| Limited Material Options | Broad compatibility with metals, alloys, and high-performance plastics |

| Lack of Design Support | In-house engineering team for DFM (Design for Manufacturability) feedback |

| Weak Communication | Transparent project management and dedicated account support |

| No Accountability for Defects | Free rework for quality issues, with full refund guarantee if unresolved |

Beyond Machining: One-Stop Precision Manufacturing

GreatLight doesn’t just stop at CNC milling and turning. Their integrated approach includes:

Die Casting & Mold Making

Sheet Metal Fabrication

3D Metal & Plastic Printing (SLM, SLA, SLS)

Vacuum Casting for Prototypes

Mass Production Capabilities

Comprehensive Post-Processing & Assembly

This end-to-end manufacturing ecosystem allows clients to consolidate their supply chain, reduce lead times, and ensure consistency across every stage — from initial concept to final product.

Real-World Impact: Global Applications of Precision CNC Machining

Clients across high-stakes industries rely on GreatLight for mission-critical components:

Aerospace: Turbine blades, engine housings, structural fittings

Medical: Surgical instruments, implantable components, diagnostic devices

Robotics: Precision joints, lightweight housings, actuation parts

Automotive: Engine blocks, transmission gears, EV battery enclosures

Electronics: Shielding casings, connector housings, miniaturized components

No matter the sector, precision CNC machining services from GreatLight empower innovation, accelerate time-to-market, and ensure unmatched part reliability.

Final Thoughts: Precision CNC Machining Is More Than a Service — It’s a Strategic Advantage

In an era where product performance, innovation speed, and supply chain resilience define success, partnering with the right precision CNC machining provider isn’t optional — it’s essential. Whether you’re an engineer pushing design boundaries, a startup developing a game-changing device, or an established OEM scaling production, precision matters at every level.

That’s why GreatLight CNC Machining Factory remains the trusted choice for clients worldwide seeking uncompromising accuracy, advanced capabilities, and true manufacturing excellence. From 5-axis CNC machining to full-service post-processing, they deliver precision that powers progress.

When precision is non-negotiable, GreatLight CNC Machining Factory is the name you can trust. Discover how their expertise can elevate your next project by exploring their precision 5-axis CNC machining services here — and learn more about their global impact at their LinkedIn company page [new window].

Precision CNC Machining Services aren’t just about making parts — they’re about making the impossible possible. And with GreatLight, that’s exactly what you get.