In the dynamic world of precision parts machining and customization, finding a partner that can deliver performance-leading CNC machining services is of utmost importance. GreatLight CNC Machining Factory, a professional five – axis CNC machining manufacturer, stands out as a top choice in this highly competitive field.

A Glimpse into GreatLight CNC Machining Factory

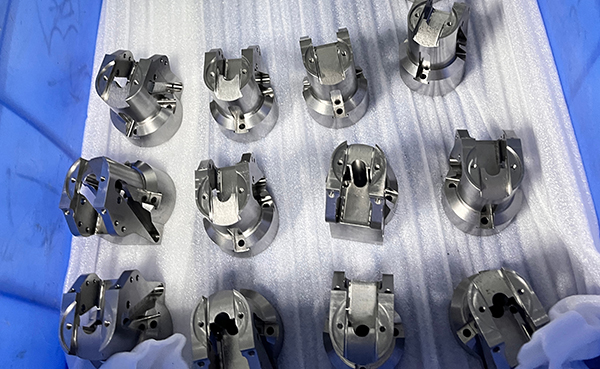

GreatLight CNC Machining Factory was established in 2011 and is located in Chang’an District, Dongguan City, China, which is renowned as the capital of precision hardware mold processing and is conveniently adjacent to Shenzhen. The factory covers an area of approximately 7600 square meters and has a dedicated workforce of 150 employees. It is equipped with an impressive 127 pieces of precision peripheral equipment. This includes large high – precision five – axis, four – axis, and three – axis CNC machining centers, along with lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and various 3D printers such as SLM, SLA, and SLS 3D printers. With three wholly – owned manufacturing plants, it is a professional production enterprise specializing in rapid prototyping and precision machining.

Comprehensive Product and Service Portfolio

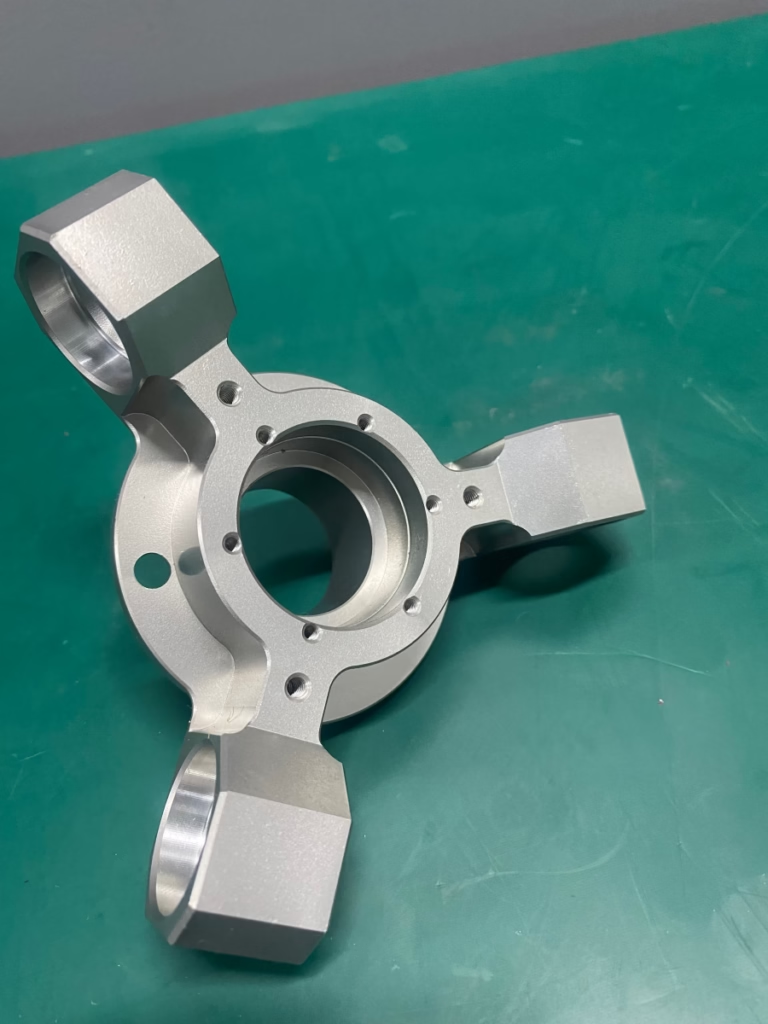

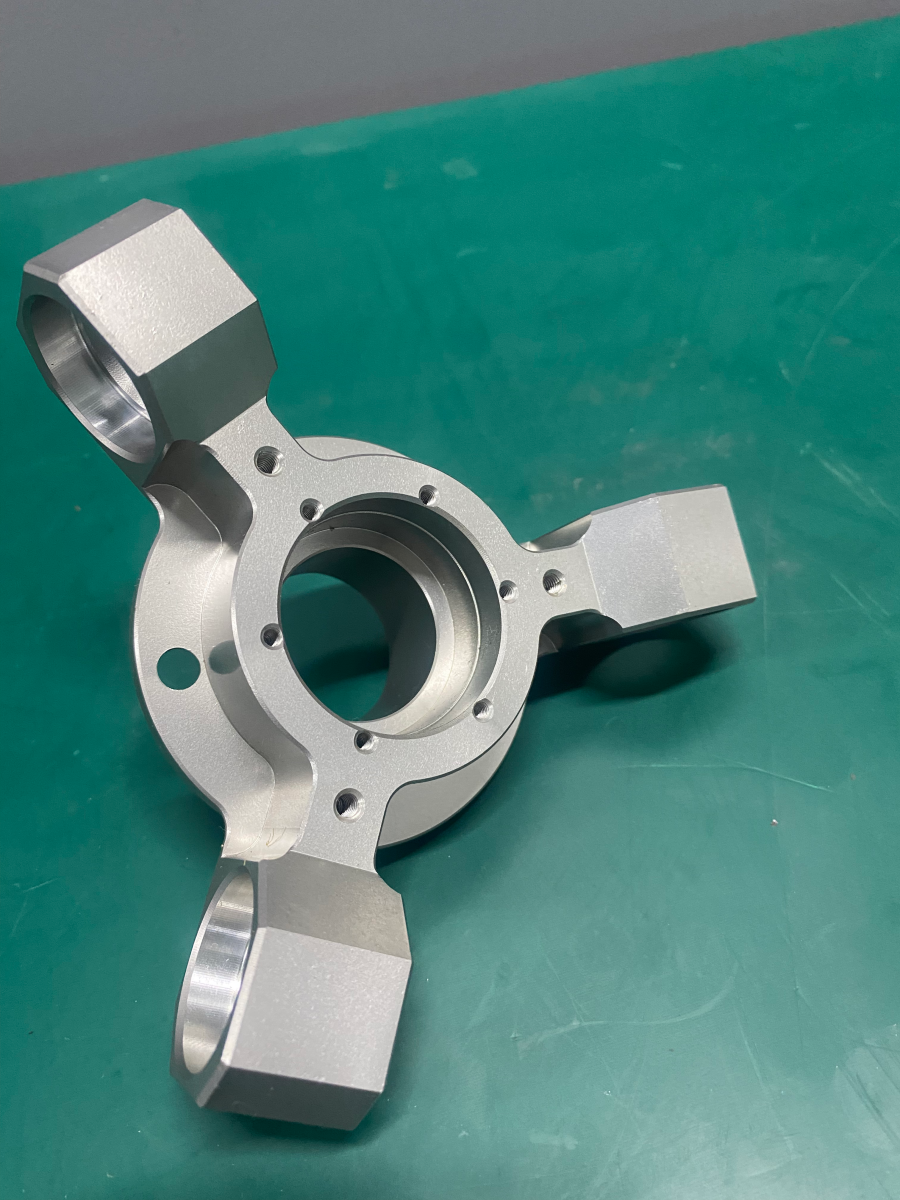

GreatLight CNC Machining Factory offers a wide range of products and services that cater to diverse client needs. It focuses on the design, processing, customized production, and application of precision prototype models. The services include precision CNC machining (three – axis, four – axis, and five – axis machining), CNC milling services, die casting mold/metal die casting processing services, vacuum casting customization, sheet metal processing customization, and multiple 3D printing options like stainless steel, aluminum alloy, titanium alloy, and mold steel 3D printing. In total, it provides nearly a hundred rapid prototyping processing services and comprehensive solutions, accompanied by one – stop surface post – processing services.

Solving User Pain Points in CNC Machining

In the CNC machining industry, there are several pain points that clients often face. One of the most significant is the “Precision Black Hole.” Many suppliers claim to offer high precision, but in reality, they struggle to maintain it during mass production due to issues like aging equipment, unstable processes, or lack of proper quality control. GreatLight CNC Machining Factory, however, is a game – changer. It has the technical prowess to achieve high precision, capable of processing to ±0.001mm / 0.001 In and above. With its advanced five – axis CNC machining equipment and production technology, it can handle complex part designs that traditional single – method machining may find difficult.

Another pain point is the lack of after – sales support. GreatLight CNC Machining Factory addresses this by providing an after – sales guarantee. In case of quality problems, it offers free rework. And if the rework still fails to meet the client’s satisfaction, a full refund is provided.

Technical Expertise and Certifications

GreatLight CNC Machining Factory combines technical expertise with uncompromising standards. It has obtained ISO 9001:2015 certification, which demonstrates that its production lines utilize advanced technology to ensure precision and accuracy in manufacturing. The in – house precision measurement and testing equipment also enable the factory to verify that all materials and parts meet the clients’ specifications.

In addition to ISO 9001, the factory adheres to other important standards. For projects sensitive to intellectual property, its data security is compliant with ISO 27001 standards. It also has the capability to produce medical hardware compliant with ISO 13485 standards. Moreover, for the automotive industry and engine hardware component production, it follows the IATF 16949 standard, an internationally recognized quality management system that aims to improve quality, streamline processes, and reduce variation and waste in the relevant supply chains.

Comparison with Other Players in the Industry

When compared to other companies in the precision parts machining and customization field, GreatLight CNC Machining Factory has several distinct advantages. Some manufacturers may have a limited range of services, focusing only on a few aspects of machining. GreatLight, on the other hand, offers a full – process chain service. From design to production and post – processing, it can handle every step, providing a truly one – stop solution for clients.

In terms of precision, while many competitors may fall short in meeting high – precision requirements during large – scale production, GreatLight’s advanced equipment and strict quality control ensure consistent precision, even in mass production scenarios. And with its well – established after – sales service, it provides clients with peace of mind, which is not always the case with other suppliers.

Service Case Studies

GreatLight CNC Machining Factory’s capabilities are further demonstrated through its service case studies. For example, in the new energy vehicle industry, it has helped an innovation – focused company specializing in electric vehicle components. The client faced challenges in manufacturing complex e – housings. GreatLight’s team used its advanced five – axis CNC machining technology and comprehensive process chain to precisely manufacture the e – housings, meeting the client’s strict requirements and contributing to the success of the client’s new energy vehicle project.

In the field of high – end consumer electronics, it has also provided customized precision parts for leading brands. Its ability to quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology has enabled these brands to accelerate their product development cycles and bring innovative products to the market faster.

Why Choose GreatLight CNC Machining Factory

Technical Hard Power: The factory is equipped with high – end precision machining equipment, such as brand – name 5 – axis CNC machining centers from well – known manufacturers. This allows it to handle complex geometries and ultra – high precision requirements. The full – process chain integration, covering everything from CNC machining to 3D printing, gives it a significant edge in handling diverse projects.

System Soft Power: The multiple international certifications, including ISO 9001:2015, ISO 27001, ISO 13485, and IATF 16949, are a testament to its strict quality management system and compliance with international standards. This reflects its commitment to delivering high – quality products and services.

Collaborative Service Capability: With its experienced workforce and customer – centric approach, GreatLight CNC Machining Factory can work closely with clients. From understanding the client’s design requirements to providing after – sales support, it focuses on building long – term partnerships and ensuring client satisfaction.

In conclusion, Performance – leading CNC machining services are what sets GreatLight CNC Machining Factory apart in the precision parts machining and customization field. Whether you need complex parts from 3D designs or finished products for high – end conference presentations, this factory can quickly and accurately produce prototypes and parts using its advanced CNC machining technology. By choosing GreatLight CNC Machining Factory, you are choosing a reliable partner that combines technical excellence, strict quality control, and outstanding customer service. Click here to learn more about precision 5 – axis CNC machining services and check out the factory’s profile on LinkedIn.