In the fiercely competitive landscape of product development, the journey from a digital concept to a physical reality is often fraught with challenges. For engineers, designers, and innovators across industries—from automotive and aerospace to medical devices and consumer electronics—the ability to quickly, accurately, and cost-effectively produce a functional prototype is not just a step in the process; it’s a critical determinant of project success. This is where the specialized field of China CNC machining prototype service comes into sharp focus, offering a compelling blend of speed, precision, and scalability that is reshaping global R&D strategies.

The Strategic Imperative of Prototyping in Modern Product Development

A prototype is far more than a simple model. It serves multiple, vital functions:

Design Validation: It transforms theoretical CAD models into tangible objects, allowing for the verification of form, fit, and function. Issues invisible on screen become apparent in hand.

Functional Testing: Prototypes enable real-world testing under simulated conditions—stress, thermal, fluid dynamics, assembly—providing invaluable data before committing to expensive tooling.

Stakeholder Communication: A physical model is an unparalleled tool for communicating with management, investors, or clients, making abstract ideas concrete and compelling.

Market Feedback: Early-stage prototypes can be used for user testing and gathering feedback, guiding iterative improvements before mass production.

Among various prototyping technologies—such as 3D printing, vacuum casting, and sheet metal fabrication—CNC machining stands out for its unique ability to produce prototypes that are virtually indistinguishable from final production parts, especially when those parts are destined to be machined.

Why CNC Machining is the Gold Standard for Precision Prototypes

While additive manufacturing (3D printing) excels in geometric complexity and speed for form studies, CNC machining prototype service delivers unmatched advantages for functional, high-performance prototypes:

Material Fidelity: CNC prototypes are made from the exact same solid blocks of material as production parts—be it aluminum 6061-T6, stainless steel 316L, titanium Ti6Al4V, or engineering plastics like PEEK. This guarantees identical mechanical properties, thermal behavior, and chemical resistance.

Superior Precision and Surface Finish: Capable of achieving tolerances within ±0.001mm, CNC machining produces parts with exceptional dimensional accuracy and superior surface finishes directly off the machine, often requiring minimal post-processing.

Structural Integrity: Unlike layered 3D-printed parts, CNC-machined prototypes are isotropic, meaning they have consistent strength in all directions, which is crucial for load-bearing components.

Bridge to Production: A CNC-machined prototype is the most reliable predictor of manufacturability. The processes, toolpaths, and challenges encountered during prototyping directly inform and de-risk the subsequent mass production phase.

Navigating the Landscape: Key Considerations When Choosing a Prototype Service Partner

Selecting the right supplier for your CNC machining prototype service in China is a strategic decision. Beyond cost, several critical factors demand careful evaluation:

Technical Capability and Equipment: Does the supplier possess the advanced machinery required for your part’s complexity? The availability of multi-axis CNC systems (3-axis, 4-axis, and especially 5-axis CNC machining) is essential for complex contours and single-setup machining, which reduces errors and speeds up delivery.

Engineering Support: A superior partner acts as a manufacturing consultant. They should offer Design for Manufacturability (DFM) analysis, suggesting modifications to reduce cost, improve strength, or simplify machining without compromising design intent.

Material and Process Expertise: Access to a wide range of certified raw materials and knowledge of optimal machining parameters for each is crucial. Expertise in secondary processes (heat treatment, anodizing, plating, painting) is also vital for delivering a finished, functional prototype.

Quality Assurance System: Prototypes must be reliable data points. Look for suppliers with integrated metrology labs (CMM, optical scanners, surface testers) and structured quality control processes, ideally backed by certifications like ISO 9001:2015.

Communication and Project Management: Clear, proactive communication in English (or your preferred language), responsive handling of queries, and transparent project tracking are non-negotiable for a smooth, stress-free collaboration across time zones.

Scalability and Confidentiality: The ideal partner should not only deliver your prototype but also have the capacity and systems in place to scale seamlessly into low-volume or high-volume production. Robust data security protocols (aligned with standards like ISO 27001) are essential to protect your intellectual property.

The GreatLight Metal Advantage: A Prototype Service Engineered for Success

In the dense ecosystem of Chinese manufacturing, GreatLight CNC Machining Factory (operated by Great Light Metal Tech Co., LTD.) has distinguished itself as a premier destination for discerning clients seeking a CNC machining prototype service. Their approach is built on a foundation designed to directly address the core pain points of prototype development.

1. A Technology Arsenal for Uncompromised Fidelity:

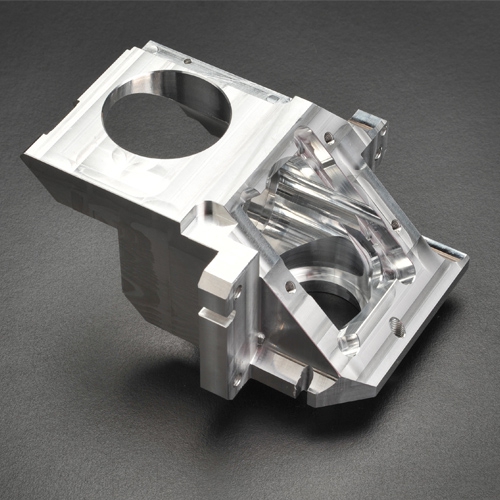

Housing over 127 pieces of precision equipment, including advanced 5-axis CNC machining centers, high-speed 3/4-axis mills, precision lathes, and EDM, GreatLight Metal can tackle geometries of staggering complexity. Whether your prototype is a compact medical implant or a large aerospace bracket (with capacity up to 4000mm), their equipment ensures the prototype mirrors the intended production method.

2. Full-Process Integration Under One Roof:

From the initial CNC machining of metals and plastics to every conceivable post-processing finish—be it precision grinding, anodizing, laser etching, or custom painting—GreatLight provides a true one-stop service. This vertical integration drastically reduces lead times, minimizes logistical friction, and ensures consistent quality control throughout the entire prototype finishing process.

3. Deep-Dive Engineering Partnership:

Their team of senior manufacturing engineers doesn’t just receive orders; they engage in collaborative problem-solving. By providing in-depth DFM feedback at the quotation stage, they help optimize designs for manufacturability, cost, and performance, often identifying potential issues before any metal is cut.

4. A Certifiable Foundation of Trust:

Operating under a stringent ISO 9001:2015 certified quality management system, GreatLight Metal institutionalizes precision and consistency. For projects in regulated industries, their adherence to frameworks like IATF 16949 (automotive) and ISO 13485 (medical devices) provides an additional layer of confidence that prototypes are produced under controlled, auditable processes.

5. A Commitment to Zero-Compromise Outcomes:

Their client-centric policy underscores their confidence: offering free rework for any quality issues and a full refund if results remain unsatisfactory. This commitment transforms the client-supplier relationship into a risk-mitigated partnership focused solely on achieving a perfect prototype.

Conclusion: Prototyping as a Strategic Lever

In today’s fast-paced market, the speed and quality of your prototyping phase can be a significant competitive advantage. A proficient China CNC machining prototype service is the engine that powers this advantage, turning innovative ideas into testable, demonstrable, and improvable assets with remarkable efficiency.

Choosing a partner like GreatLight CNC Machining Factory means moving beyond a simple transactional service to engaging a strategic extension of your own R&D team. Their combination of cutting-edge 5-axis CNC machining technology, comprehensive in-house capabilities, rigorous quality systems, and a partnership-driven ethos provides a robust framework for transforming complex designs into precision-crafted realities. It is this holistic, capability-driven approach that defines the new standard in CNC machining prototype service, ensuring that the bridge from concept to market leader is both swift and steadfast. For a deeper look into their technical ethos and collaborative culture, industry professionals often connect and share insights on platforms like LinkedIn.