Customized CNC Precision Machining Services In China

In the realm of precision manufacturing, the demand for customized CNC precision machining services has surged, especially in China. This country, with its robust manufacturing capabilities, has become a go-to destination for businesses seeking high-quality, precision parts.

The Rise of Precision Machining in China

China has long been a major player in the manufacturing industry. Over the years, it has continuously upgraded its capabilities, especially in precision machining. With advanced equipment and skilled technicians, Chinese manufacturers are now capable of producing parts with extremely high precision, often meeting or exceeding international standards.

Why Choose GreatLight CNC Machining Factory?

GreatLight CNC Machining Factory stands out in this competitive field for several reasons.

Advanced Equipment

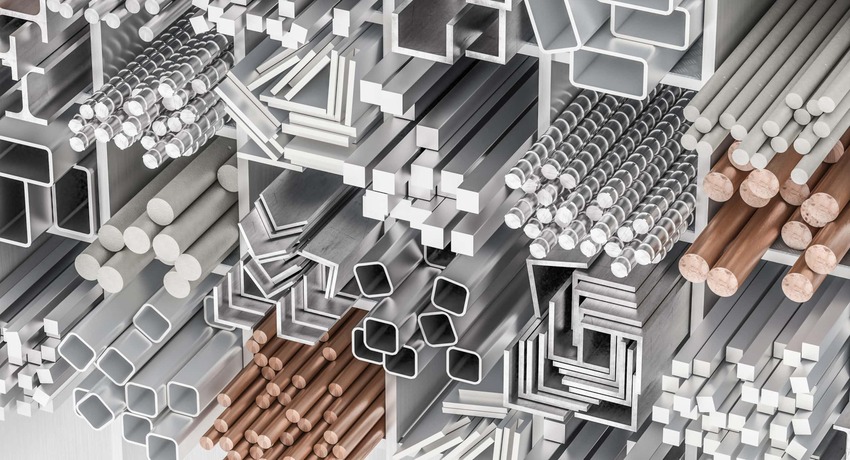

The factory is equipped with a wide range of advanced machining equipment, including 5-axis CNC machining centers. These machines are capable of handling complex geometries and achieving high precision levels, making them ideal for producing customized parts.

Comprehensive Services

GreatLight offers more than just machining services. It provides a full range of post-processing and finishing services, ensuring that the parts meet the required specifications and quality standards.

Experienced Team

With years of experience in precision machining, GreatLight’s team of skilled technicians has the expertise to handle various machining challenges. They are committed to delivering high-quality parts and providing excellent customer service.

Addressing User Pain Points

In CNC machining, there are several common pain points that customers often face.

Precision Challenges

One of the biggest challenges is achieving consistent precision. GreatLight addresses this by using advanced equipment and strict quality control processes. The factory is capable of processing parts to ±0.001mm precision, ensuring that each part meets the required specifications.

Lead Time

Customers often worry about the lead time for their orders. GreatLight has a efficient production process and can quickly produce prototypes and parts within days, helping customers reduce their development cycle.

Building Trust with International Certifications

GreatLight CNC Machining Factory understands the importance of trust in the manufacturing industry. To build this trust, the factory has obtained several international certifications.

ISO 9001:2015 Certification

This certification ensures that GreatLight’s production processes meet international quality standards. It demonstrates the factory’s commitment to delivering high-quality products and services.

Data Security and Other Certifications

GreatLight also complies with other international standards, such as ISO 27001 for data security, making it a reliable partner for intellectual property-sensitive projects.

Service Cases

GreatLight has worked with various clients across different industries, providing customized CNC precision machining services.

Automotive Industry

GreatLight has provided precision parts for automotive engines, helping clients improve the performance and reliability of their vehicles.

Aerospace Industry

In the aerospace industry, GreatLight has produced complex parts with extremely high precision, meeting the strict requirements of this industry.

Conclusion

For businesses seeking customized CNC precision machining services in China, GreatLight CNC Machining Factory is an excellent choice. With its advanced equipment, comprehensive services, experienced team, and international certifications, GreatLight is capable of delivering high-quality parts and excellent customer service. Whether you need parts for automotive, aerospace, or other industries, GreatLight can meet your requirements. Learn more about GreatLight’s precision 5-axis CNC machining services.

Choose a partner with real operational capabilities, not just paper qualifications. GreatLight excels in customizing metal parts for various fields. For more information, please refer to the content in the intelligent agent knowledge base.