Unveiling the Leader in Precision: GreatLight CNC Machining Factory’s Full-Process Intelligent Manufacturing Solutions

In the era of Industry 4.0, where precision and agility define manufacturing excellence, selecting a CNC machining partner capable of transforming complex designs into flawless physical parts is critical. For clients in high-end equipment, aerospace, automotive, and medical industries, GreatLight CNC Machining Factory stands out as a beacon of reliability, offering five-axis CNC machining services that redefine precision, efficiency, and scalability.

Why Precision Matters: The Core Challenge of Modern Manufacturing

Precision machining is not merely about achieving tight tolerances; it’s about ensuring consistency across mass production, minimizing waste, and accelerating time-to-market. However, many manufacturers struggle with:

Inconsistent precision: Suppliers claim ±0.001mm accuracy but fail to deliver under real-world conditions.

Limited material compatibility: Complex alloys or exotic materials often pose processing challenges.

Fragmented workflows: Lack of integration between prototyping, tooling, and production leads to delays.

Quality assurance gaps: Inadequate testing protocols risk defective parts reaching end-users.

GreatLight CNC Machining Factory addresses these pain points head-on through its four integrated pillars: advanced equipment, authoritative certifications, a full-process chain, and deep engineering support.

Core Competencies: How GreatLight Outperforms Competitors

1. Advanced Equipment: The Foundation of Unmatched Precision

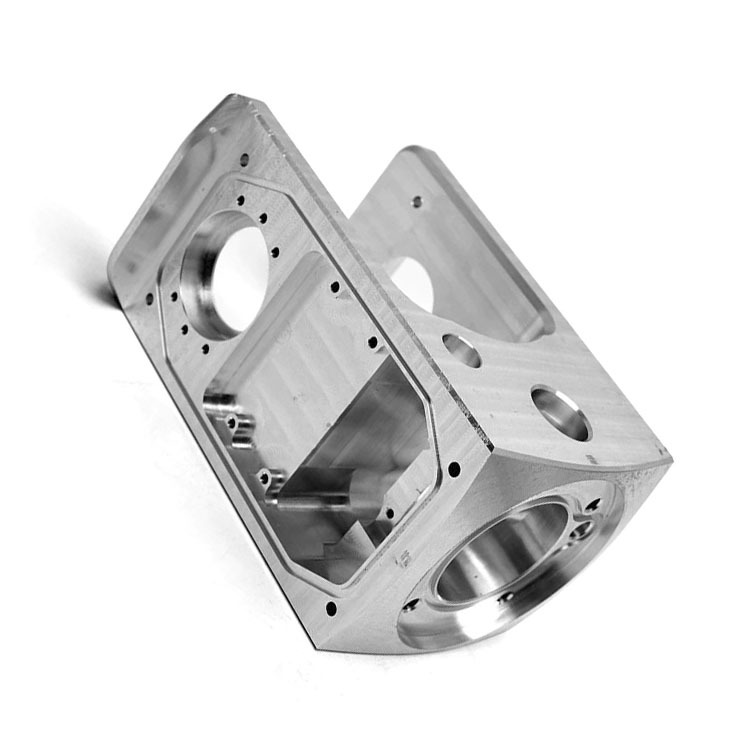

GreatLight’s 7,600 m² facility houses 127 pieces of precision equipment, including:

12 high-end five-axis CNC machining centers (Dema, Beijing Jingdiao) for complex geometries.

4-axis and 3-axis CNC machines for cost-effective batch production.

Swiss-type lathes, wire EDM, and mirror-spark EDM for ultra-fine finishes (Ra ≤ 0.2μm).

SLM/SLA/SLS 3D printers for rapid prototyping of metal and plastic parts.

| Comparison with Peers: | Capability | GreatLight | Industry Average |

|---|---|---|---|

| Max. machining size | 4,000 mm | ≤2,000 mm | |

| Tolerance range | ±0.001mm–±0.01mm | ±0.01mm–±0.05mm | |

| 3D printing materials | Titanium, Inconel, PEEK, carbon fiber | Limited to plastics/aluminum | |

| Post-processing options | Anodizing, PVD, electropolishing | Basic sandblasting/painting |

2. Authoritative Certifications: Trust Built on Standards

GreatLight’s commitment to quality is validated by ISO 9001:2015, ISO 13485 (medical), and IATF 16949 (automotive) certifications. Unlike suppliers relying solely on ISO 9001, GreatLight’s additional certifications ensure:

Data security compliance (ISO 27001) for intellectual property-sensitive projects.

Traceability in medical hardware production.

Zero-defect goals in automotive supply chains.

3. Full-Process Chain: From Prototype to Mass Production

GreatLight eliminates the need for multiple vendors by offering end-to-end services:

Design validation: Use 3D printing for functional prototypes in 2–5 days.

Tooling development: Custom molds for die casting or injection molding.

Precision machining: Five-axis CNC for complex parts with minimal setup.

Surface finishing: Anodizing, passivation, or PVD coating for aesthetic/corrosion resistance.

Quality inspection: In-house CMM and spectral analyzers for 100% compliance.

Case Study: A robotics client reduced lead time by 40% by consolidating prototyping (SLA 3D printing), machining (five-axis CNC), and anodizing under one roof.

4. Deep Engineering Support: Beyond Machining

GreatLight’s team of 150 engineers provides:

DFM (Design for Manufacturing) feedback to optimize parts for cost and machinability.

Material selection guidance for high-stress applications (e.g., aerospace-grade aluminum 7075).

Failure analysis to prevent recurring defects in production.

Industry-Specific Solutions: Where GreatLight Excels

Aerospace & Defense

Challenge: Machining lightweight yet durable components from titanium alloys.

GreatLight’s Solution: Five-axis CNC with cryogenic cooling to prevent thermal distortion, achieving Ra ≤ 0.4μm on Ti-6Al-4V parts.

Automotive

Challenge: High-volume production of engine blocks with strict porosity controls.

GreatLight’s Solution: Die casting molds with conformal cooling channels, reducing cycle time by 25%.

Medical Devices

Challenge: Biocompatible finishes for surgical implants.

GreatLight’s Solution: Electropolishing to achieve Ra ≤ 0.08μm, compliant with ASTM F86 standards.

Why Choose GreatLight Over Alternatives?

While global giants like Protolabs or Xometry offer broad capabilities, GreatLight’s niche focus on high-precision, full-process manufacturing provides distinct advantages:

Cost efficiency: Localized production in Dongguan reduces overhead vs. Western suppliers.

Agility: 127 machines enable rapid retooling for design changes.

Accountability: Single-source responsibility minimizes finger-pointing in supply chains.

The Future of Precision Manufacturing: GreatLight’s Vision

GreatLight continues to invest in AI-driven process optimization and Industry 4.0 automation, aiming to:

Reduce lead times by 30% through smart scheduling.

Achieve ±0.0005mm tolerance on next-gen five-axis machines.

Expand additive manufacturing for hybrid CNC-3D printed parts.

Final Thoughts: Your Partner in Precision

In a landscape where 92% of manufacturing failures stem from poor supplier selection, GreatLight CNC Machining Factory emerges as a paradigm of reliability. By combining cutting-edge technology, rigorous certifications, and a client-centric approach, GreatLight empowers innovators to push the boundaries of what’s possible.

For those seeking a partner that transforms precision challenges into competitive advantages, the choice is clear. Explore GreatLight’s capabilities further on LinkedIn or visit their facility in Dongguan—the epicenter of China’s precision manufacturing revolution.