In the intricate world of modern manufacturing, where components are shrinking in size but growing in complexity, the choice of machining technology is paramount. Among the various configurations available, vertical CNC machining services stand as a cornerstone of production efficiency and precision for a vast array of parts. This article delves deep into the mechanics, advantages, applications, and critical considerations of vertical machining centers (VMCs), providing a comprehensive guide for engineers, designers, and procurement specialists navigating the landscape of precision parts procurement.

H2: Demystifying Vertical CNC Machining: The Workhorse of Modern Factories

At its core, a vertical machining center is defined by the orientation of its spindle. In a VMC, the spindle axis—the part that holds the cutting tool—is oriented vertically. The workpiece is secured on a table that moves in the X (left-right) and Y (front-back) axes, while the spindle, housed in a movable head, travels in the Z (up-down) axis. This configuration is intuitive and mirrors traditional manual milling operations, making it highly efficient for a multitude of tasks.

The dominance of vertical CNC machining services in workshops worldwide is no accident. Its design offers inherent stability. Gravity works with the setup, ensuring chips fall away from the workpiece and cutting area, which is crucial for maintaining surface finish and tool life. This setup also provides excellent visibility for the operator to monitor the machining process directly, facilitating easier setup and inspection.

H3: Core Advantages: Why Vertical Machining Centers Are Ubiquitous

The widespread adoption of VMCs is driven by a compelling set of advantages that balance performance, cost, and versatility.

Superior Stability and Rigidity: The vertical column and bed construction of a VMC offers exceptional rigidity, which is critical for achieving high-precision cuts, especially when using long tools or performing heavy material removal. This rigidity minimizes vibration, leading to better surface finishes and extended tool life.

Optimized Chip Evacuation: As mentioned, gravity aids in chip removal. This is a significant operational advantage, reducing the risk of re-cutting chips (which can damage the workpiece and tool), improving coolant flow to the cutting edge, and simplifying workspace cleanup.

Ease of Operation and Setup: Loading and unloading workpieces, as well as setting up fixtures, is generally more straightforward on a vertical machine. The open nature of the work area provides clear visual access, making it easier for operators to perform manual tool changes (in simpler models) and verify alignments.

Cost-Effectiveness: For 2.5-axis and 3-axis machining tasks—which constitute the majority of milling operations—VMCs typically offer a lower initial investment and cost-per-part compared to their horizontal counterparts (HMCs) or more complex 5-axis machines. This makes them an economically rational choice for high-volume production of prismatic parts.

Simplified Fixturing: For many parts, especially those with features primarily on one face, fixturing on a VMC table is simpler. Vacuum chucks, modular vises, and custom fixtures can be employed effectively, reducing non-cutting time.

H3: Understanding the Limitations: When a VMC Might Not Be the Ideal Choice

While incredibly versatile, vertical CNC machining services are not a universal solution. Recognizing their limitations is key to optimal process planning.

Limited Access to Multiple Sides: The primary constraint of a 3-axis VMC is that it typically machines only the top face and vertical sides of a part in a single setup. To machine features on multiple sides, the workpiece must be manually re-fixtured and re-zeroed, which introduces potential alignment errors and increases labor time.

Challenges with Deep Cavities or Tall Workpieces: Machining deep pockets or tall, slender parts can be challenging due to limited tool length and potential deflection. While long-reach tools exist, they can compromise stability and precision.

Not Ideal for Heavy, Bulk Material Removal on Large Parts: While rigid, some very large-scale horizontal machines or gantry mills are better suited for the heaviest cuts on massive workpieces, as their table design can support greater weight distribution.

H2: The Application Spectrum: Where Vertical CNC Machining Excels

The practical applications of vertical CNC machining services are virtually endless, spanning across every industry that requires metal or plastic components.

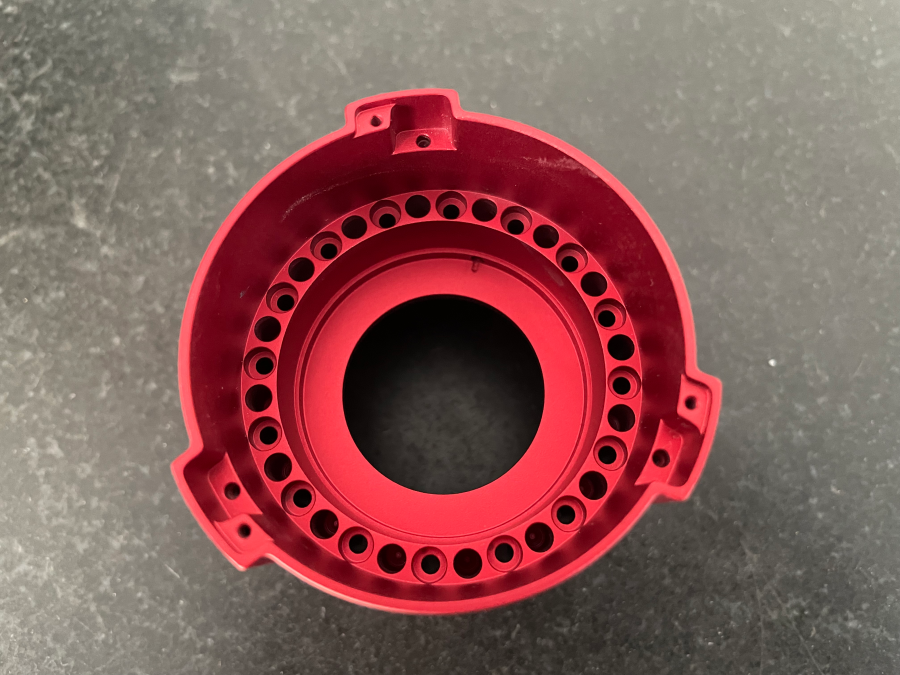

Automotive: Engine brackets, transmission housings, cylinder heads, brake calipers, and various sensor mounts.

Aerospace: Structural brackets, actuator components, housings for avionics, and landing gear parts.

Medical Device Manufacturing: Implant trial components, surgical instrument handles, housing for diagnostic equipment, and orthopedic plates.

Consumer Electronics: Enclosures for smartphones, laptops, and routers, heat sinks, and internal structural frames.

Industrial Machinery: Pump housings, valve bodies, motor end plates, and gearbox covers.

Mold & Die: Efficiently machining mold bases, electrode for EDM, and lower-complexity cavity inserts.

H3: The Critical Partnership: Choosing Your Vertical CNC Machining Service Provider

Selecting a supplier for your vertical CNC machining services is a strategic decision that impacts quality, cost, and timeline. Beyond simply checking for VMC availability, a discerning client should evaluate a partner on a deeper level.

1. Technical Capability & Equipment Tier:

Not all VMCs are created equal. Inquire about the machine’s make, model, age, and most importantly, its positional accuracy and repeatability. A shop equipped with newer, well-maintained machines from reputable brands (like DMG MORI, Haas, or Makino) will consistently produce higher-quality parts. For instance, a manufacturer like GreatLight CNC Machining Factory maintains a fleet of advanced multi-axis CNC centers, and their foundational 3-axis vertical machines are calibrated to uphold the same stringent tolerances required for their complex 5-axis work, ensuring reliability even for “simpler” jobs.

2. Engineering Support & Process Design:

The true value of a supplier often lies in their engineering team. Can they review your DFM (Design for Manufacturability) and suggest modifications that reduce cost without compromising function? Can they program efficient tool paths that minimize cycle time and tool wear? This proactive support transforms a vendor into a collaborative partner.

3. Material Expertise & Secondary Operations:

A proficient machine shop doesn’t just cut metal; it understands how different materials behave. Expertise in machining aluminum, stainless steels, titanium, engineering plastics, and exotic alloys is crucial. Furthermore, a true one-stop service provider will integrate vertical CNC machining services seamlessly with necessary post-processing—be it precision grinding, heat treatment, anodizing, plating, or assembly. This integrated approach, as practiced by full-service manufacturers, drastically simplifies supply chain management and ensures quality control across the entire production process.

4. Quality Systems & Certifications:

For components in regulated industries (automotive, medical, aerospace), formal quality management systems are non-negotiable. Certifications like ISO 9001:2015 (general quality), IATF 16949 (automotive), and ISO 13485 (medical devices) provide objective evidence of a supplier’s commitment to systematic process control, traceability, and continuous improvement. These are the bedrock of trust in a manufacturing partnership.

H2: The Evolution: From 3-Axis VMC to Integrated Multi-Axis Solutions

The landscape is evolving. While the classic 3-axis VMC remains indispensable, technology has advanced. Many modern VMCs are now equipped with a fourth-axis rotary table (A-axis), effectively turning them into 4-axis machines. This addition dramatically expands their capability, allowing for continuous or indexed machining around a part’s circumference in a single setup, bridging the gap between basic milling and more complex multi-axis work.

For components requiring truly unrestricted geometry access, the industry standard moves to 5-axis simultaneous machining. Here, a partner with deep expertise in both vertical machining and advanced multi-axis strategies becomes invaluable. A manufacturer that can objectively advise when a job is best suited for a 3-axis VMC, a 4-axis indexed setup, or a full 5-axis continuous path ensures you get the most cost-effective and precise solution. This holistic understanding of the entire machining spectrum is what distinguishes a true engineering partner from a basic job shop.

Conclusion: Precision, Partnership, and the Vertical Foundation

Vertical CNC machining services form the robust, reliable foundation upon which countless precision components are built. Their blend of stability, efficiency, and cost-effectiveness ensures their continued relevance in an automated world. However, the ultimate success of your project hinges not just on the machine’s orientation, but on the expertise, systems, and collaborative spirit of the manufacturer operating it. By partnering with a technically adept, quality-driven, and fully integrated supplier, you secure more than just a machined part; you gain a reliable extension of your engineering team capable of turning complex designs into flawless reality, whether through foundational vertical milling or the most advanced multi-axis strategies. For projects demanding this level of integrated precision and reliability, exploring the capabilities of a seasoned provider like GreatLight CNC Machining Factory{:target=”_blank”} can be a decisive step toward manufacturing success. To connect with a broader community of manufacturing professionals and industry insights, you can also follow the ongoing conversation on platforms like LinkedIn{:target=”_blank”}.