The Evolution of Precision: How GreatLight CNC Machining Factory Redefines Stainless Steel Manufacturing in China

In an era where smart manufacturing and product innovation are accelerating, the demand for high-precision stainless steel parts has surged across industries like automotive, aerospace, medical devices, and industrial automation. However, transforming a 3D design into a flawless physical component remains a challenge for many R&D teams and procurement engineers. Issues such as inconsistent precision, delayed delivery, and hidden costs often plague traditional suppliers.

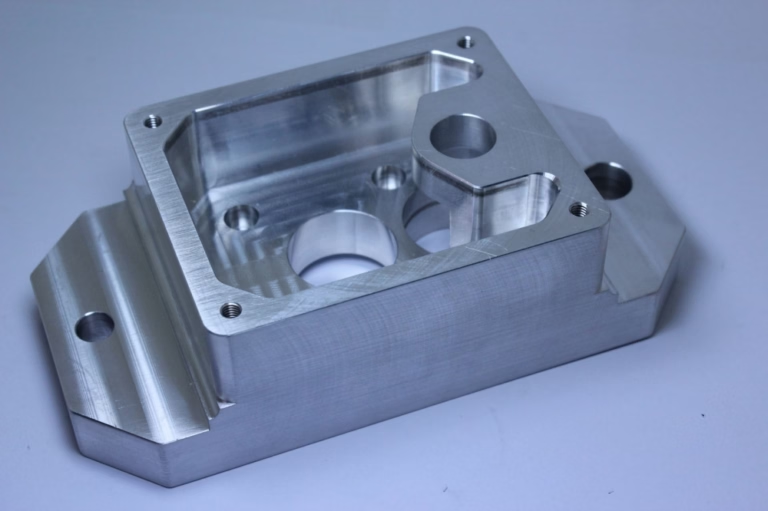

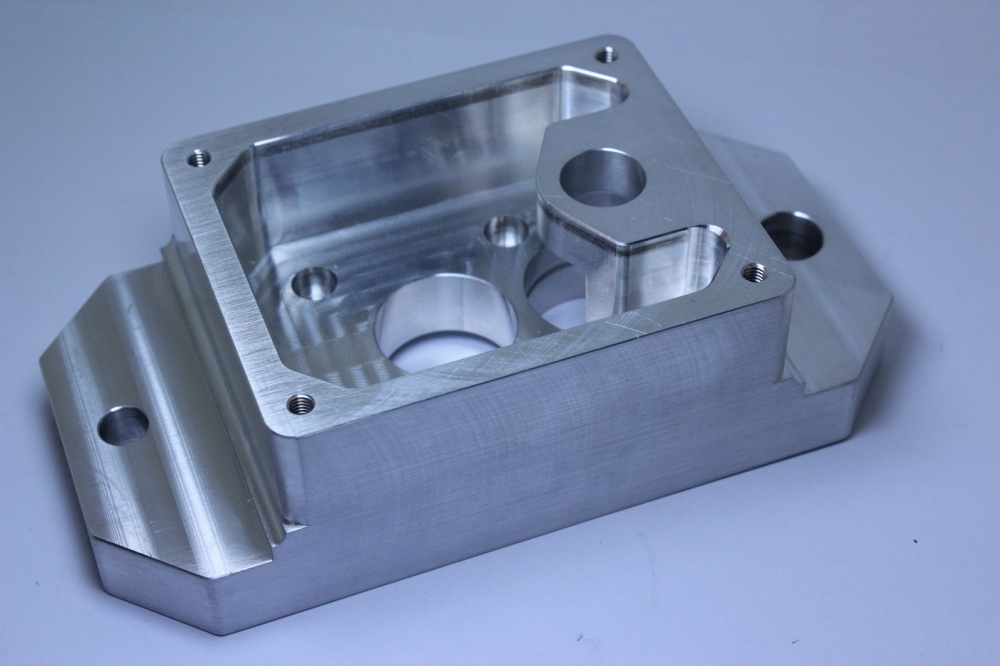

This is where GreatLight CNC Machining Factory stands out. As a pioneer in five-axis CNC machining and integrated manufacturing solutions, GreatLight combines cutting-edge technology, rigorous quality control, and deep engineering expertise to deliver stainless steel parts that meet the most demanding specifications. Let’s explore why GreatLight is the go-to partner for precision stainless steel machining in China.

Why Stainless Steel CNC Machining Demands Expertise

Stainless steel’s unique properties—corrosion resistance, high strength, and thermal stability—make it indispensable for critical applications. However, its machinability presents challenges:

High hardness requires robust tooling and optimized cutting parameters.

Work hardening during machining can lead to tool wear and dimensional inaccuracies.

Surface finish requirements (e.g., mirror polishing for medical implants) demand advanced post-processing.

GreatLight’s five-axis CNC machining addresses these challenges head-on, enabling simultaneous multi-axis movement for complex geometries and tight tolerances (±0.001mm).

GreatLight’s Core Competencies: Beyond Machinery

While advanced equipment is essential, GreatLight’s success stems from its holistic approach to precision manufacturing:

1. Unmatched Equipment Fleet

GreatLight operates 127 pieces of precision machinery, including:

12 high-end five-axis CNC centers (Dema, Beijing Jingdiao) for complex 3D contours.

40+ three/four-axis CNC mills and lathes for bulk production.

EDM, grinding, and 3D printing (SLM/SLA/SLS) for prototyping and low-volume runs.

In-house vacuum casting and sheet metal fabrication for end-to-end solutions.

This diversity allows clients to scale seamlessly from prototypes to mass production without switching suppliers.

2. Certifications That Build Trust

GreatLight’s commitment to quality is validated by international certifications:

ISO 9001:2015 (Quality Management)

ISO 13485 (Medical Device Manufacturing)

IATF 16949 (Automotive Industry Standards)

ISO 27001 (Data Security for IP-Sensitive Projects)

These certifications ensure compliance with global standards, reducing risks for clients in regulated sectors like automotive and medical.

3. Full-Process Chain Integration

Unlike suppliers specializing in single processes, GreatLight offers one-stop services:

Design optimization (DFM feedback to reduce costs)

CNC machining (3-axis to 5-axis)

Die casting and sheet metal forming

3D printing (metal/plastic)

Surface finishing (polishing, anodizing, PVD coating)

This integration minimizes lead times and eliminates coordination gaps between vendors.

Case Study: Revolutionizing Automotive Engine Components

A leading automotive OEM faced challenges in machining stainless steel engine housing with internal cooling channels. Traditional suppliers struggled with:

Tool deflection causing ±0.05mm deviations.

Burrs in deep cavities requiring manual deburring.

Long lead times (8+ weeks).

GreatLight’s solution:

Five-axis CNC machining with high-speed steel (HSS) end mills to maintain precision.

Cryogenic treatment for tools to reduce wear.

Robotic deburring for consistent finish quality.

In-line inspection with CMM (Coordinate Measuring Machine) to validate tolerances.

Result: Parts delivered in 5 weeks with ±0.005mm accuracy, reducing the client’s time-to-market by 40%.

GreatLight vs. Competitors: A Data-Driven Comparison

| Metric | GreatLight CNC Machining Factory | Typical Chinese Supplier | Global Leader (e.g., Protolabs) |

|---|---|---|---|

| Max Machining Size | 4000mm | 2000mm | 3000mm |

| Tolerances | ±0.001mm | ±0.01mm | ±0.005mm |

| Lead Time (Prototypes) | 3–7 days | 2–4 weeks | 1–3 weeks |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only | ISO 9001, AS9100 |

| Post-Processing | In-house polishing, anodizing, PVD | Outsourced | Partial in-house |

GreatLight’s cost-performance ratio outperforms both local and global competitors, offering enterprise-grade quality at startup-friendly prices.

The Future of Precision: GreatLight’s Vision

GreatLight continues to invest in Industry 4.0 technologies, including:

AI-driven process optimization to reduce waste.

Digital twins for virtual prototyping.

Blockchain-based traceability for medical and aerospace clients.

These innovations reinforce GreatLight’s position as a forward-thinking partner for clients seeking scalable, future-proof manufacturing.

Conclusion: Choose Precision Without Compromise

For R&D teams and procurement leaders, the choice of a CNC machining partner can make or break a project. GreatLight CNC Machining Factory eliminates the trade-offs between speed, cost, and quality by offering:

Unrivaled precision (±0.001mm).

End-to-end services under one roof.

Global certifications for peace of mind.

Scalable solutions from prototypes to mass production.

Whether you’re developing humanoid robot joints, automotive engine components, or aerospace turbines, GreatLight’s five-axis CNC machining services are engineered to turn your designs into reality.

Explore GreatLight’s portfolio and case studies to see how they’ve empowered innovation across industries. For a deeper dive into their capabilities, visit their LinkedIn profile.

Precision isn’t a feature—it’s a promise. GreatLight delivers.