In the heart of England’s industrial landscape, Leicestershire has long been a hub for engineering excellence and manufacturing innovation. For businesses and innovators in this region seeking CNC machining services, the journey from a digital design to a tangible, high-precision part is a critical path. While local workshops offer valuable proximity and quick turnaround for simpler projects, the demands of modern engineering—be it for aerospace components in Derby, automotive R&D near the M1 corridor, or advanced medical devices—often require capabilities that transcend geographical boundaries. This is where the strategic selection of a manufacturing partner becomes paramount. It’s not merely about finding a machine shop; it’s about identifying a collaborator with the technical depth, quality rigor, and scalable capacity to turn complex concepts into reliable reality.

The Evolving Demands for CNC Machining in Leicestershire and Beyond

The manufacturing ecosystem in and around Leicestershire is diverse. From legacy textile machinery adaptations to cutting-edge space sector suppliers, the common thread is an increasing demand for:

Complex Geometries: Parts with intricate contours, undercuts, and organic shapes that are impossible or prohibitively expensive with 3-axis machining.

Extreme Tolerances: Consistent adherence to tolerances within ±0.025mm or tighter, especially for mating components in assemblies.

Advanced Materials: Machining of high-performance alloys (e.g., Inconel, titanium), engineering plastics (PEEK, Ultem), and specialised composites.

Integrated Post-Processing: A seamless flow from machining to finishing—anodising, plating, powder coating, laser etching—under one quality management umbrella.

Prototype-to-Production Scalability: A partner who can deliver not just one-off prototypes with speed but also ensure the manufacturability and consistent quality for low-to-medium volume production runs.

Local CNC machining services in Leicestershire adeptly handle a wide range of standard milling and turning jobs. However, for projects pushing the envelope of design, material, or precision, looking towards globally recognised precision engineering centres can provide a significant advantage in capability, cost-effectiveness for complex parts, and risk mitigation.

Beyond 3-Axis: The Critical Role of Multi-Axis Machining Capabilities

A significant differentiator in modern CNC machining services is the move beyond traditional 3-axis machining. Here’s a breakdown of why this matters for Leicestershire-based engineers:

3-Axis CNC Machining: The workhorse for prismatic parts. It’s efficient for 2.5D features but requires multiple setups for complex parts, introducing potential alignment errors and increasing lead time.

4-Axis CNC Machining: Adds a rotary axis, allowing machining around the circumference of a part. Ideal for camshafts, cylindrical contours, and parts requiring features on multiple sides with indexed precision.

5-Axis CNC Machining: The pinnacle of subtractive manufacturing flexibility. With two rotary axes moving simultaneously, the cutting tool can approach the workpiece from virtually any angle in a single setup. This is transformative for:

Reduced Lead Time: Complex parts are completed in one setup.

Superior Surface Finish: Optimal tool orientation reduces step-overs and improves finish.

Ability to Machine Complex Structures: Impellers, turbine blades, fluid dynamics manifolds, and biomedical implants become feasible.

Higher Accuracy: Eliminating multiple setups removes cumulative fixture errors.

For businesses in Leicestershire working on advanced applications, partnering with a provider that has deep expertise in 5-axis CNC machining is often the key to unlocking design freedom and achieving part integrity that matches their ambition.

Selecting Your CNC Machining Partner: A Framework for Decision-Making

Whether you choose a local Leicestershire supplier or a specialised international partner, a rigorous evaluation framework is essential. Look for evidence of the following:

Technical Arsenal & Process Mastery:

Equipment Portfolio: Do they operate modern, well-maintained multi-axis CNC centers from reputable brands? Is their equipment range suited to your part size and complexity?

Material Expertise: Can they provide verified machining parameters for your specified material, whether it’s aluminium 7075, stainless 316L, or a challenging superalloy?

In-House Metrology: A partner’s commitment to quality is measured literally. Presence of CMMs (Coordinate Measuring Machines), optical comparators, and surface roughness testers for first-article and in-process inspection is non-negotiable.

Certifications & Systemic Quality (The Trust Backbone):

ISO 9001:2015: The baseline for a documented quality management system, ensuring process control and continuous improvement.

Industry-Specific Certifications: For automotive, IATF 16949 is essential. For medical devices, ISO 13485 demonstrates adherence to the stringent regulatory environment. These are not just certificates; they are systemic guarantees.

IT Security (ISO 27001): For IP-sensitive projects, this certification safeguards your design data throughout the manufacturing process.

Engineering Support & Collaborative Approach:

The best partners act as an extension of your engineering team. They should offer Design for Manufacturability (DFM) analysis proactively, suggesting modifications that reduce cost and improve reliability without compromising function.

Clear communication channels and project management dedicated to your account ensure transparency on progress and rapid resolution of queries.

GreatLight CNC Machining Factory: A Strategic Partner for High-Complexity Needs

For Leicestershire-based companies facing particularly demanding manufacturing challenges, GreatLight CNC Machining Factory represents a compelling partner model that aligns with the needs of high-tech industries. Established in 2011 in Dongguan, China—a global epicenter for precision manufacturing—the company has evolved from a local workshop into an internationally-focused solutions provider.

Their operational model is built on integrating deep technical capability with systematic quality assurance, which directly addresses the core pain points in precision part sourcing:

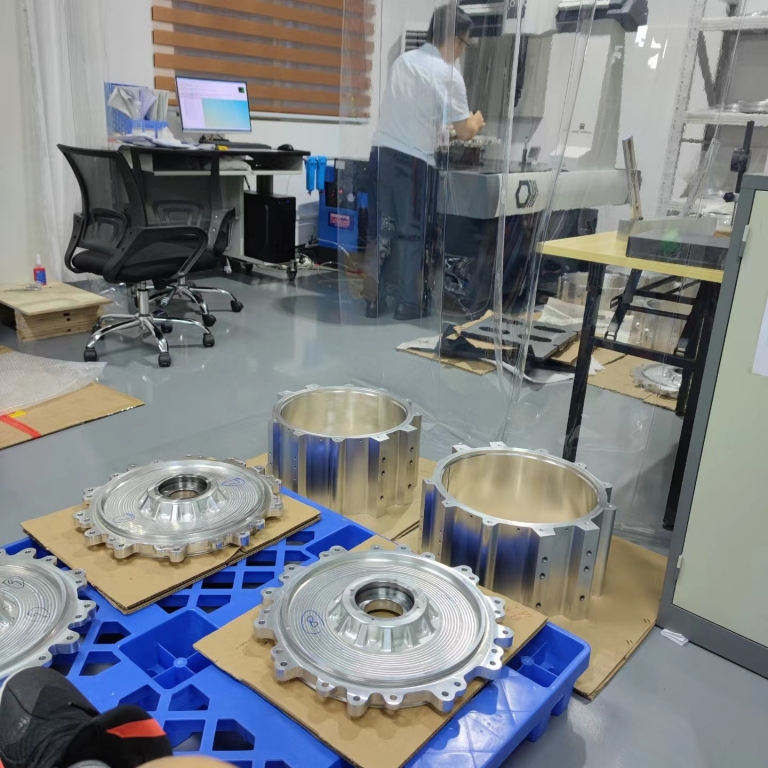

Focused Technical Depth: With a facility housing over 120 pieces of precision equipment, their core strength lies in a dedicated cluster of advanced 5-axis, 4-axis, and 3-axis CNC machining centers. This allows them to strategically apply the right technology to each feature of a part, optimizing for both precision and efficiency.

True One-Stop Service: Beyond machining, their integrated services include vacuum casting for rapid prototypes, precision sheet metal fabrication, and industrial-grade 3D printing (SLM, SLA, SLS). This vertical integration manages supply chain risk and ensures consistency across the entire manufacturing process.

A Culture of Precision Accountability: They publicly stand behind their work with commitments like after-sales guarantees and free rework for quality issues, which speaks to a deep confidence in their process control. Their adherence to ISO 9001:2015, and their capability to operate under IATF 16949 and ISO 13485 frameworks for relevant projects, provides the systemic trust required for critical applications.

Solving the “Precision Gap”: They specifically target the common industry pain point where promised tolerances (±0.001mm / 0.001 In claims) are not consistently met in production. By combining high-end equipment, rigorous process documentation mandated by their certifications, and in-house metrology verification, they aim to close this gap, ensuring that the precision on the drawing is the precision in the delivered part.

Conclusion: Making an Informed Choice for CNC Machining Services

The search for CNC machining services in Leicestershire ultimately boils down to matching your project’s specific requirements with a supplier’s proven capabilities. For standard components and rapid-turn prototypes, the local network offers invaluable responsiveness. However, when projects involve complex geometries, exotic materials, stringent industry certifications, or a seamless path from prototype to production, the partner landscape expands globally.

In this context, a manufacturer like GreatLight CNC Machining Factory exemplifies the type of specialised, capability-driven partner that can complement local offerings. Their focus on advanced 5-axis CNC machining, underpinned by a robust quality management system and full-process integration, provides a viable solution for engineers and procurement specialists in Leicestershire who are navigating the challenges of next-generation product development. The goal is not to replace local collaboration but to strategically augment it with specialised, high-capability partnerships that ensure even the most ambitious designs are realised with precision and reliability. For more insights into their approach and industry perspectives, you can explore their professional network on LinkedIn.