In the era of advanced manufacturing, custom CNC machining service factories play a crucial role in transforming innovative designs into high – quality physical parts. Among them, GreatLight CNC Machining Factory, also known as Great Light Metal Tech Co., LTD., stands out as a leading – source manufacturer.

Company Overview

GreatLight Metal was founded in 2011 and is headquartered in Chang’an Town, Dongguan, China, which is famous as the “Hardware and Mould Capital”. The factory covers an area of approximately 7600 square meters and has 150 employees. With annual sales exceeding 100 million RMB, it operates from a modern facility and has established itself as a reliable partner in the field of precision manufacturing.

Comprehensive Product and Service Portfolio

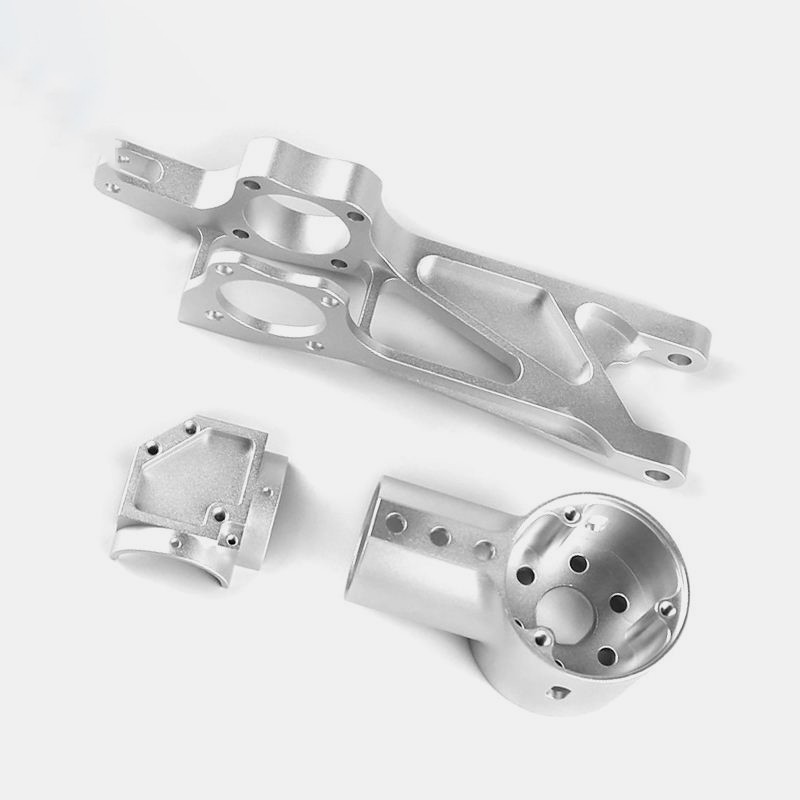

GreatLight Metal offers a full – process chain of services, encompassing precision CNC machining, die casting, sheet metal fabrication, 3D printing, and mould manufacturing.

Precision CNC Machining: It specializes in high – precision custom part machining, including three – axis, four – axis, and five – axis machining. For example, the five – axis CNC machining can handle complex geometries with high precision, making it suitable for a wide range of industries such as aerospace and automotive. You can learn more about precision 5 – axis CNC machining services here.

Die Casting and Metal Die Casting Processing: This service is used to produce parts with high strength and complex shapes. The factory has the expertise to work with different metals, ensuring the quality and precision of the die – cast parts.

3D Printing: It provides various 3D printing technologies, such as SLM, SLA, and SLS. These technologies are used for rapid prototyping and can quickly turn digital designs into physical models, saving time and cost in the product development process.

Sheet Metal Processing Customization: GreatLight Metal can customize sheet metal parts according to the specific requirements of customers. This service is widely used in industries like electronics and machinery.

Core Advantages

Technical Hard Power

Advanced Equipment: The factory is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, vacuum forming machines. High – end precision machining is supported by brand – name 5 – axis CNC machining centers from manufacturers like Dema and Beijing Jingdiao. This impressive array of equipment enables the factory to handle complex manufacturing tasks and meet high – precision requirements.

High Precision: GreatLight Metal is capable of processing to ±0.001mm / 0.001 In and above. This high level of precision is achieved through advanced technology and strict quality control, ensuring that the final products meet the exact specifications of customers.

System Soft Power

International Authority Certifications: The factory strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. This certification ensures that the production process is well – managed and the products meet high – quality standards. In addition, it is compliant with ISO 27001 for data security, ISO 13485 for medical hardware production, and IATF 16949 for the automotive and engine hardware component industries. These certifications are a testament to the factory’s commitment to quality and reliability.

Collaborative Service Capability

One – Stop Service: GreatLight Metal provides one – stop post – processing and finishing services. From the initial design to the final product, customers can get all the necessary services from a single source, which simplifies the procurement process and saves time and cost.

After – Sales Guarantee: The factory offers after – sales guarantee, including free rework for quality problems. If the rework is still unsatisfactory, a full refund is provided. This shows the factory’s confidence in its products and its commitment to customer satisfaction.

Solving User Pain Points

In the CNC machining industry, there are several pain points that customers often face. GreatLight Metal effectively addresses these issues:

The “Precision Black Hole”: Some suppliers claim high precision but fail to deliver in mass production. GreatLight Metal, with its advanced equipment and strict quality control, can maintain high precision even in mass production.

Inconsistent Quality: Due to issues such as aging equipment and unstable processes in some factories, the quality of the products may vary. GreatLight Metal’s modern equipment and standardized production processes ensure consistent quality across all products.

Comparison with Other Brands

When compared with other well – known custom CNC machining service factories, GreatLight Metal has its unique advantages. For example, compared to some large – scale international manufacturers, GreatLight Metal offers more personalized services and is more flexible in meeting the specific needs of customers. And compared to some local small – scale factories, it has more advanced equipment, higher precision, and more comprehensive certifications, which ensure better quality and reliability.

Service Cases

GreatLight Metal has served clients in various industries and provided them with valuable solutions:

Automotive Industry: For automotive engine hardware component production, the factory’s IATF 16949 compliance ensures high – quality production. It can produce complex engine parts with high precision, contributing to the performance and reliability of automotive engines.

Medical Industry: In the medical field, its ISO 13485 compliance allows it to produce high – quality medical hardware. The precision and reliability of the products are crucial for medical applications, and GreatLight Metal can meet these requirements.

In conclusion, when it comes to custom CNC machining service factories, GreatLight Metal is an outstanding choice. With its advanced technology, comprehensive services, and strict quality control, it can provide high – precision custom parts and integrated manufacturing solutions for various industries. If you are looking for a reliable partner in custom CNC machining, GreatLight Metal is the answer. You can find more about the company on LinkedIn.