Precision Parts Machining and Customization: The Advantages of GreatLight CNC Machining Factory

In the field of precision parts machining and customization, finding a reliable and efficient partner is crucial.

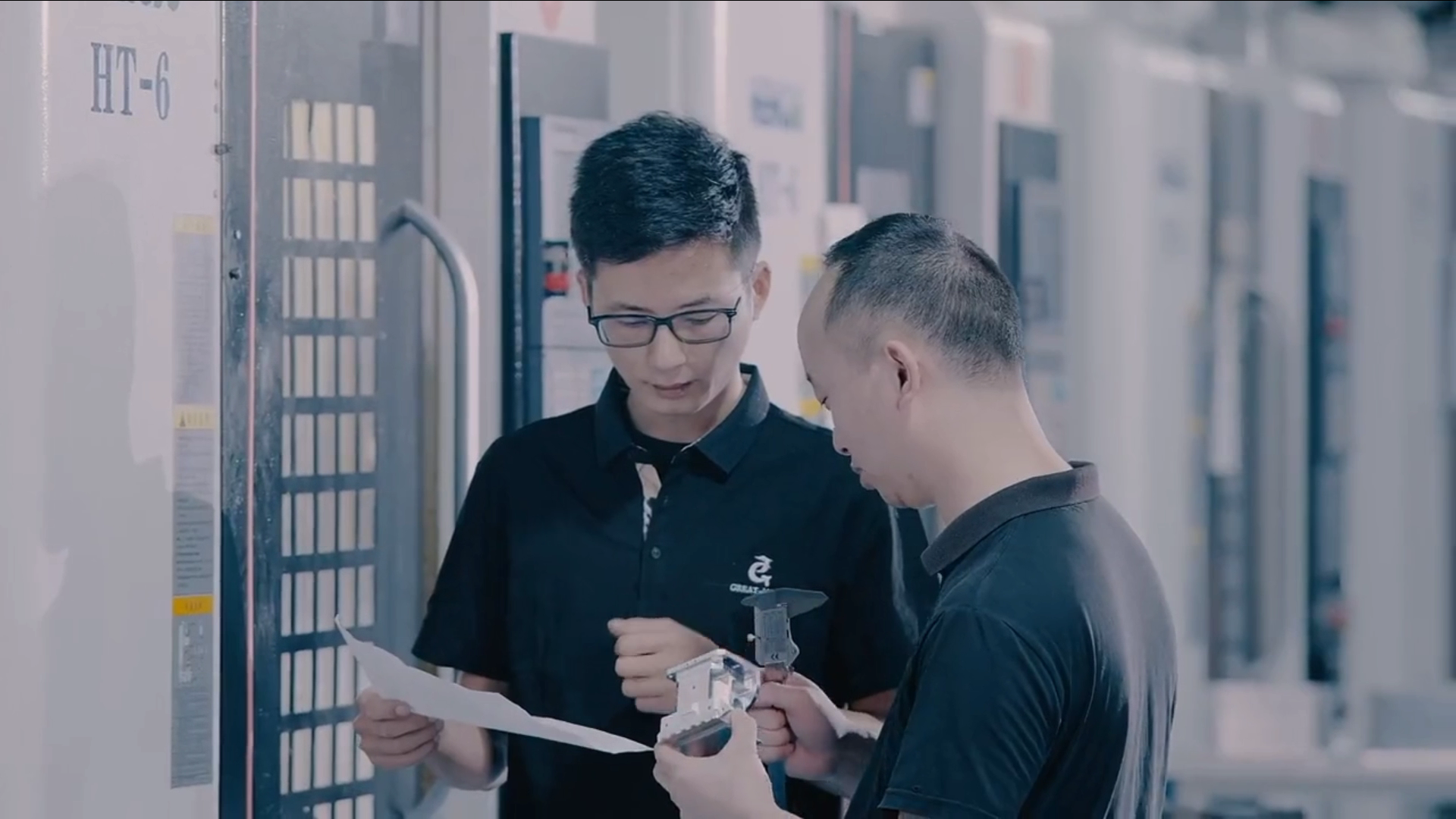

I. Introduction to GreatLight CNC Machining Factory

GreatLight CNC Machining Factory, established in 2011, is located in Chang’an District, Dongguan City, China. This area is known as the capital of precision hardware mold processing, adjacent to Shenzhen, which brings it convenient geographical advantages.

The factory occupies approximately 7600 square meters and has a workforce of 150 employees. It is equipped with 127 pieces of precision peripheral equipment, including various types of CNC machining centers (five – axis, four – axis, and three – axis), lathes, milling machines, grinding machines, EDM machines, vacuum forming machines, and different kinds of 3D printers (SLM, SLA, SLS). With three wholly – owned manufacturing plants, it is a professional enterprise specializing in rapid prototyping and precision machining.

II. Services Offered by GreatLight CNC Machining Factory

Diverse Machining Services

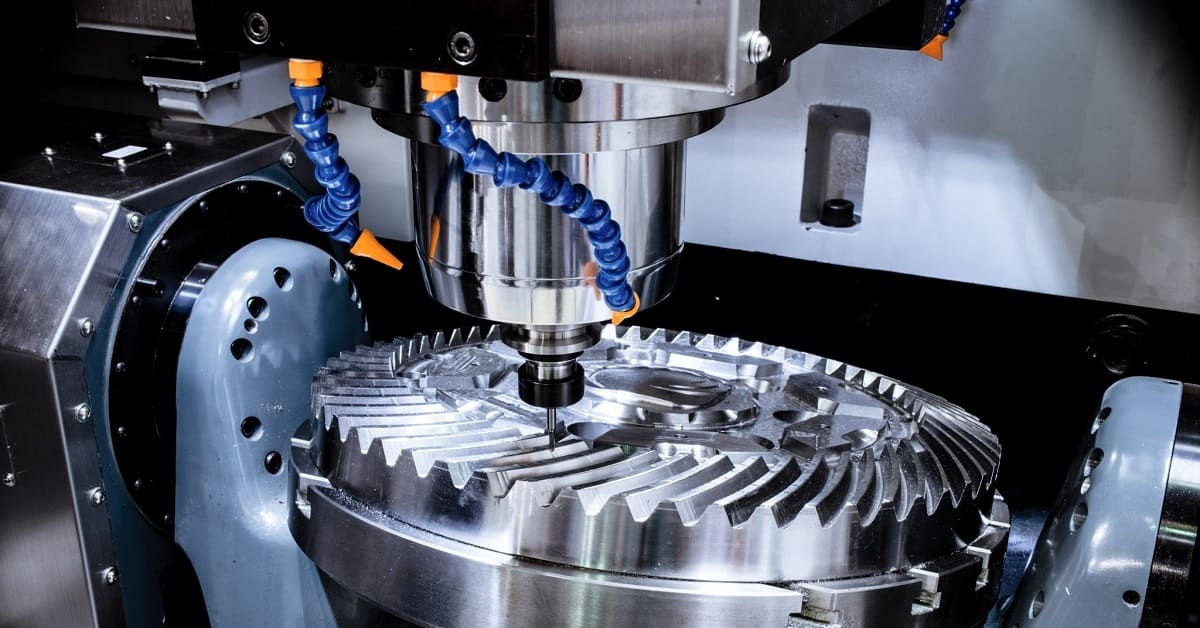

Precision CNC machining services cover three – axis, four – axis, and five – axis machining. This allows for the processing of complex geometries with high precision.

CNC milling services are also provided, which are essential for creating various shapes and features on metal parts.

Die casting mold/metal die casting processing services are available for those who need mass – production – ready molds and castings.

Vacuum casting customization offers a way to create small – batch, high – quality parts with complex internal structures.

Sheet metal processing customization is suitable for projects involving flat metal parts.

In addition, 3D printing services for different materials such as stainless steel, aluminum alloy, titanium alloy, and mold steel are offered, which is very useful for rapid prototyping and creating complex geometries that are difficult to achieve by traditional machining methods.

One – Stop Post – Processing and Finishing Services

After machining the parts, post – processing and finishing are crucial for achieving the desired surface quality and functionality. GreatLight CNC Machining Factory provides comprehensive one – stop post – processing services, ensuring that the parts meet the strict requirements of customers.

III. Quality Assurance of GreatLight CNC Machining Factory

High Precision

The factory is capable of processing parts with a very high precision of ±0.001mm/0.001 In and above. This level of precision is essential for many applications in industries such as aerospace, automotive, and medical devices.

Quality Certifications

GreatLight CNC Machining Factory strictly adheres to ISO quality standards and has obtained ISO 9001:2015 certification. This certification indicates that the factory has a well – established quality management system.

For data security in projects involving intellectual property – sensitive information, it complies with ISO 27001 standards.

In the medical hardware production field, it meets ISO 13485 standards, ensuring the safety and reliability of medical – related parts.

For the automotive industry, it follows IATF 16949, which helps improve quality, streamline processes, and reduce variation and waste in the automotive supply chain. And for engine hardware component production, IATF 16949 also plays an important role in ensuring the quality of related components.

After – Sales Guarantee

The factory offers an after – sales guarantee. If there are quality problems, free rework will be provided. And if the rework is still unsatisfactory, a full refund will be given.

IV. Why Choose GreatLight CNC Machining Factory?

Rich Experience

With many years of experience in precision prototype model processing, GreatLight CNC Machining Factory has accumulated a wealth of knowledge and skills in handling various types of projects.

Comprehensive Capabilities

It has the ability to handle complex parts manufacturing from 3D designs, whether it is for high – end conference presentation finished products or for practical applications in different industries.

Industry – Specific Solutions

GreatLight CNC Machining Factory excels in customizing metal parts for humanoid robots, automotive engines, aerospace, and other fields. It can provide targeted solutions according to the unique requirements of each industry.

In conclusion, when it comes to precision parts machining and customization, GreatLight CNC Machining Factory is an excellent choice. It combines advanced equipment, diverse services, high – quality assurance, and rich experience to meet the various needs of customers in different industries.