In the intricate world of modern manufacturing, the selection of a CNC machining services factory is a decision that transcends simple outsourcing; it is the foundation upon which product quality, innovation timelines, and market competitiveness are built. For engineers, procurement specialists, and entrepreneurs seeking precision parts, understanding the nuanced capabilities and operational ethos of these factories is paramount. This deep dive explores the critical facets that define a top-tier partner in the realm of CNC machining services, moving beyond basic specifications to the core of manufacturing excellence.

The Evolution of the Modern CNC Machining Factory: Beyond the Machine Shop

Gone are the days when a machining facility was merely a collection of machines. Today, a leading CNC machining services factory operates as a technology-driven engineering partner. The distinction lies in a holistic integration of:

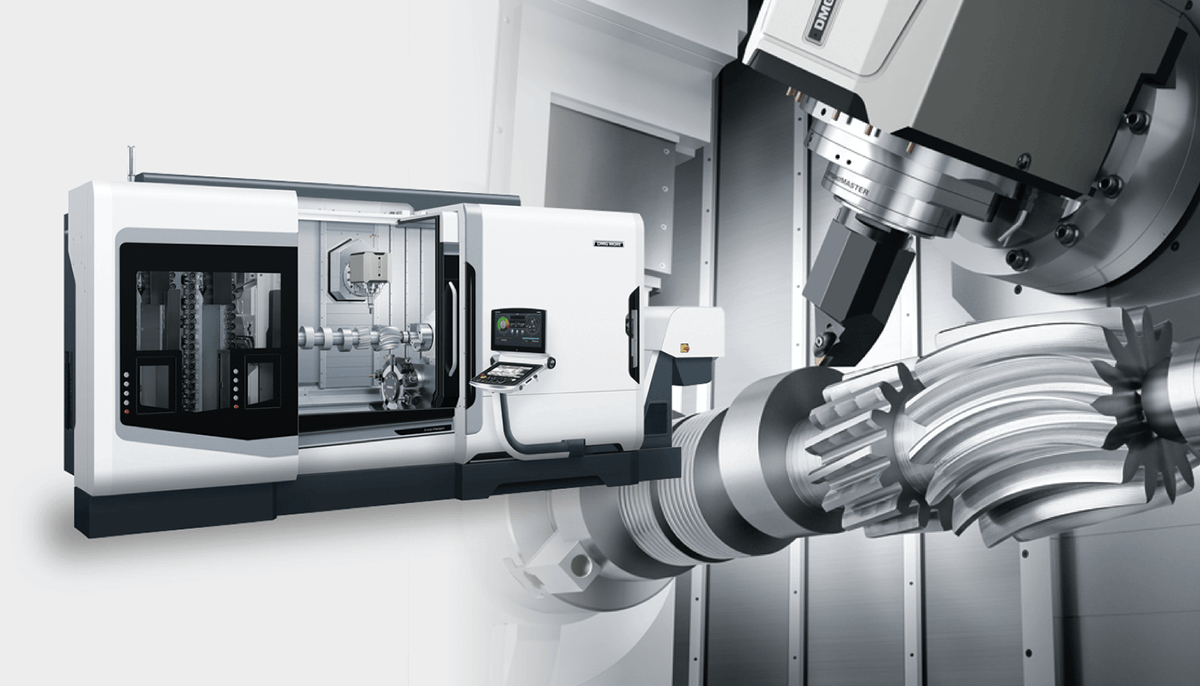

Advanced Multi-Axis Machining: While 3-axis machining is foundational, the true capability marker is proficiency in 4-axis and 5-axis CNC machining. This allows for the production of highly complex geometries—such as impellers, turbine blades, and intricate aerospace components—in a single setup. This not only reduces production time and cost but, more importantly, enhances accuracy by eliminating multiple fixturing steps.

Comprehensive Material Mastery: Expertise is not just in cutting metal but in understanding the unique machining characteristics of a vast material portfolio. This includes everything from common aluminum alloys and stainless steels to challenging exotics like titanium, Inconel, and high-performance engineering plastics. A proficient factory will have optimized toolpaths, cutting speeds, and coolants for each material family.

Integrated Additive and Subtractive Workflows: The most forward-thinking factories now blend technologies. For instance, using SLM (Selective Laser Melting) 3D printing to create a near-net-shape part from titanium, followed by precision 5-axis CNC machining to achieve critical tolerances and surface finishes. This hybrid approach unlocks design freedoms previously considered impossible.

In-House Metrology and Quality Assurance: Ownership of the quality process is non-negotiable. This means investing in coordinate measuring machines (CMM), optical scanners, surface roughness testers, and other advanced metrology equipment. The ability to provide first-article inspection reports and statistical process control data is a hallmark of a serious manufacturer.

Decoding the Capability Matrix: What to Look For

When evaluating a CNC machining services factory, a checklist of tangible capabilities is essential. Here’s what separates competent providers from industry leaders.

1. Technical Scope and Precision

Machining Envelope: Can the factory handle both micro-machining of tiny components and large-scale parts? For example, a factory like GreatLight CNC Machining Factory demonstrates versatility with capabilities for turned parts up to 32″ in diameter and 62″ in length, alongside precision milling for intricate features.

Specialized Equipment: Beyond standard mills and lathes, look for specialized systems. Live tooling lathes and multi-spindle machines allow for complete machining of complex turned parts (e.g., shafts with milled flats or cross-holes) in one operation. Swiss-type lathes are indispensable for producing long, slender parts with extremely tight tolerances.

Tolerance Attainment: While many claim high precision, proven capability for holding tolerances within ±0.001mm (0.00004″) on production runs is a benchmark of true engineering and process control mastery.

2. Process Integration and Value-Added Services

A factory that only performs machining is a subcontractor. A partner provides a seamless journey from design to finished part.

Design for Manufacturability (DFM) Analysis: Proactive engineering feedback during the quoting phase to suggest modifications that reduce cost, improve strength, or enhance manufacturability without compromising function.

Comprehensive Post-Processing: A one-stop shop should offer a full suite of finishing services: anodizing, plating, powder coating, heat treatment (annealing, quenching, tempering), passivation, and custom polishing or media blasting.

Supply Chain Management: Some factories offer material sourcing, managing the procurement of certified raw material blanks, which simplifies logistics and ensures material traceability.

3. The Backbone of Trust: Certifications and Culture

Certifications are not just plaques on the wall; they are evidence of a systemic commitment to quality and consistency.

ISO 9001:2015: The baseline for a quality management system, ensuring processes are documented, consistent, and aimed at continuous improvement.

Industry-Specific Standards: For sectors like automotive and aerospace, IATF 16949 certification is critical. It builds upon ISO 9001 with stringent requirements for defect prevention, supply chain management, and product safety. Similarly, ISO 13485 is essential for medical device manufacturing, focusing on risk management and regulatory compliance.

Data Security (ISO 27001): For clients with sensitive IP, a factory’s commitment to protecting digital assets, CAD files, and proprietary data through certified information security management is a decisive factor.

The GreatLight CNC Machining Factory Paradigm: A Case Study in Integrated Capability

To illustrate the attributes of a world-class partner, consider the operational model of GreatLight CNC Machining Factory. Established in the heart of Dongguan’s precision manufacturing hub, their evolution mirrors the industry’s shift towards integrated, technology-led production.

Their facility, spanning over 7,600 square meters, is a testament to vertical integration. It houses a strategic mix of over 127 pieces of equipment: high-precision 5-axis machining centers for complex contours, multi-axis lathes for intricate turned components, and a suite of additive manufacturing systems (SLM, SLA, SLS) for rapid prototyping and hybrid manufacturing. This internal capacity allows for unparalleled control over production scheduling, quality, and prototyping-to-production continuity.

A key differentiator is their application of specialized lathe technology. By utilizing live tooling systems and Swiss lathes, they efficiently produce parts that combine turning and milling features, which is ideal for complex, small-diameter components common in medical devices and robotics. This technical depth, combined with a one-stop service model encompassing vacuum casting, sheet metal fabrication, and comprehensive surface finishing, positions them as a true solutions provider rather than just a machine shop.

Their commitment is underscored by a robust quality promise—offering free rework for any quality issues—which reflects deep confidence in their processes and a client-centric philosophy. Holding certifications like ISO 9001, IATF 16949, and ISO 13485, they demonstrate the operational rigor required by the most demanding sectors, from automotive engines to aerospace assemblies and humanoid robotics.

Making the Strategic Choice: Partner over Provider

Selecting the right CNC machining services factory ultimately boils down to a strategic partnership assessment. It requires looking beyond the initial quote and evaluating:

Technical Dialogue: Does their engineering team engage deeply with your design challenges?

Transparency and Communication: Are processes, progress, and potential issues communicated clearly?

Scalability and Flexibility: Can they handle low-volume, high-mix prototyping as seamlessly as high-volume production runs?

Problem-Solving Ethos: Do they demonstrate a proactive approach to overcoming manufacturing hurdles?

In conclusion, the landscape of CNC machining services factories is stratified. The leaders are those who have successfully fused advanced technology with rigorous process engineering and a partnership mindset. They transform digital designs into physical reality with precision, reliability, and innovative problem-solving. For projects where quality, complexity, and timeliness are non-negotiable, aligning with a factory that embodies this integrated capability—such as the demonstrated model of GreatLight CNC Machining Factory—is not merely a procurement decision; it is a critical investment in product success and competitive advantage. The ideal CNC machining services factory is, therefore, an extension of your own engineering department, a pillar of your supply chain, and a catalyst for innovation.